System and method for multi-mode wastewater treatment by forward osmosis technology

A wastewater treatment, multi-mode technology, applied in the field of forward osmosis technology multi-mode wastewater treatment system, can solve the problems of unstable operating parameters, unclear operating conditions, missing operating data, etc., to achieve flexible and changeable operating modes, chemical cleaning The effect of low frequency and stable water production up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

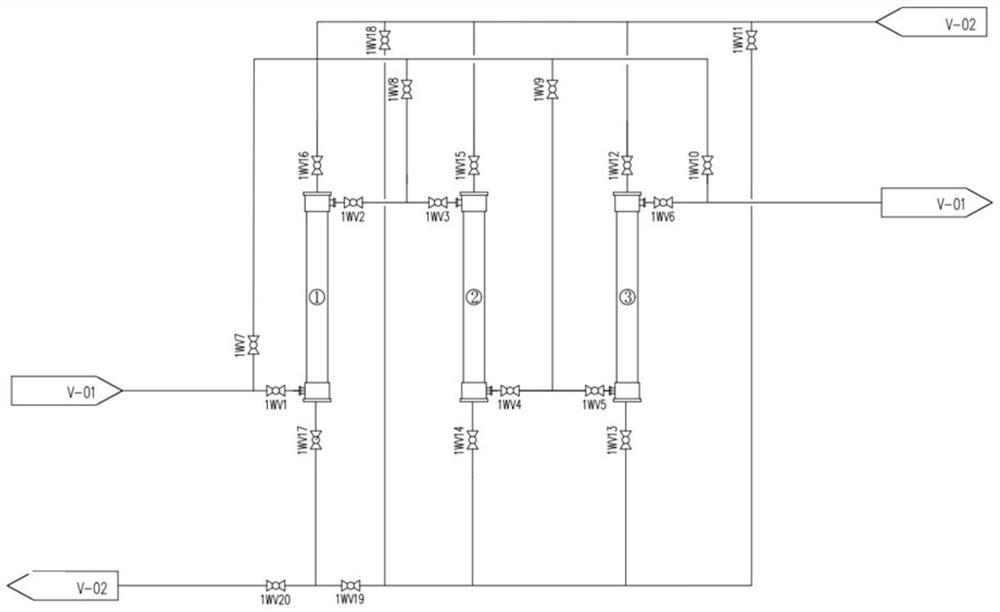

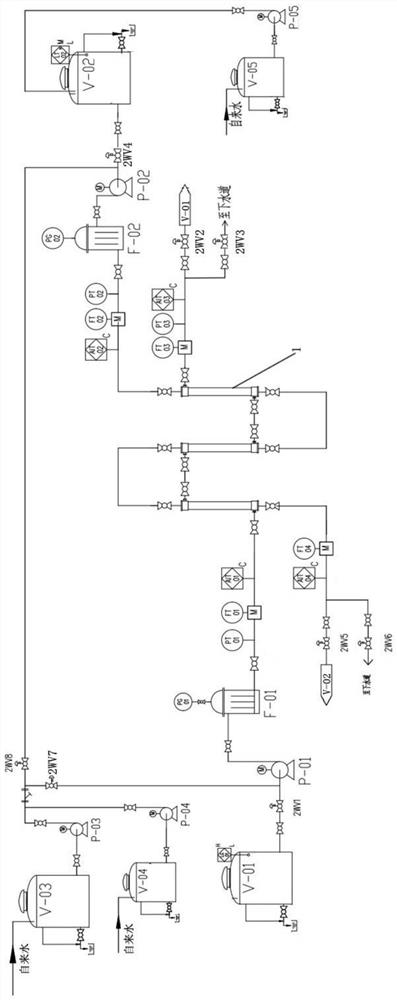

[0080] This embodiment provides a system for the multi-mode treatment of wastewater by forward osmosis technology, such as figure 2 As shown, the system includes: feed liquid tank V-01, feed liquid pump P-01, feed liquid side bag filter F-01, forward osmosis membrane unit 1, draw liquid tank V-02, draw liquid pump P -02, draw liquid side bag filter F-02, salt replenishment device, physical cleaning water tank V-03, physical cleaning water pump P-03, chemical cleaning water tank V-04 and chemical cleaning water pump P-04;

[0081] The feed liquid tank V-01 is respectively provided with a feed liquid water outlet and a feed liquid concentrated water return port;

[0082] The pipeline connected between the feed liquid outlet and the feed liquid side of the forward osmosis membrane unit is sequentially provided with a first valve 2WV1, the feed liquid pump P-01, and the feed liquid side bag filter F-01, feed liquid pressure sensor PT01, feed liquid electromagnetic flowmeter FT01...

Embodiment 2

[0092] This embodiment provides a method for treating waste water with forward osmosis technology in multiple modes. The method adopts the system for treating waste water in multiple modes with forward osmosis technology described in Example 1 to treat landfill leachate. The landfill leachate is taken from Beijing Municipality The specific water quality data of the old liquid in the first phase of a certain sanitary landfill site are shown in Table 2.

[0093] Table 2 Landfill leachate water quality data

[0094]

[0095] Including the following steps:

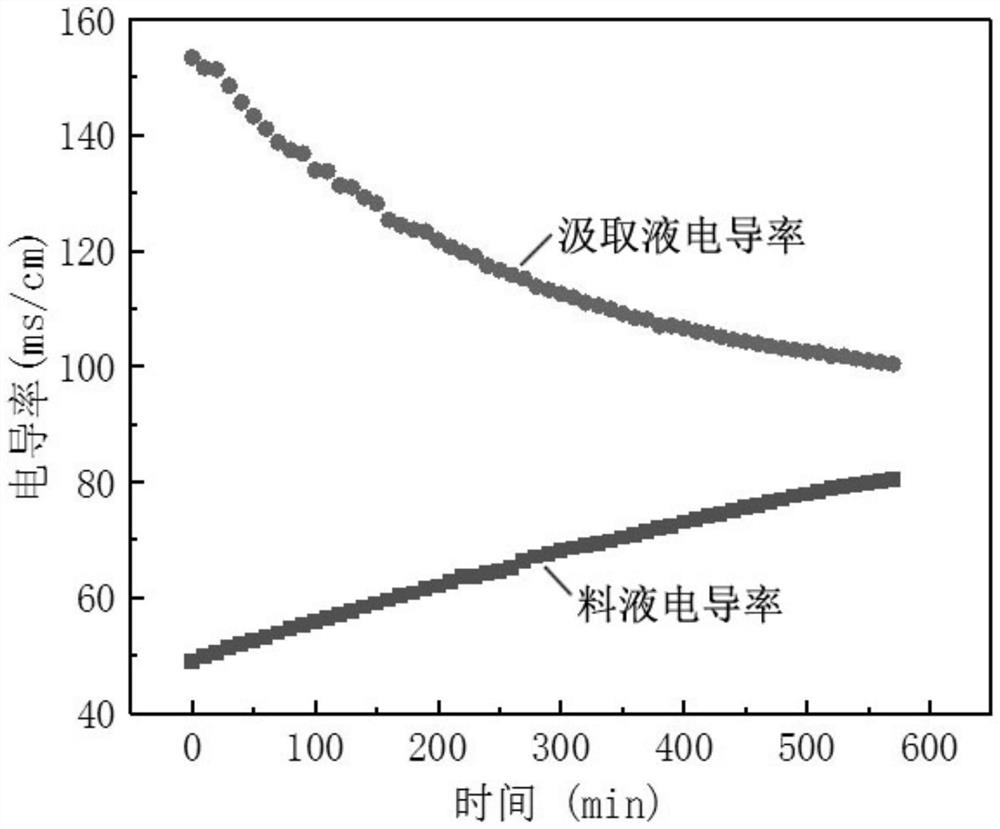

[0096] S1: Adjust the pH of the feed liquid in the feed liquid tank V-01 to a preset pH value of 5-7 through the pH adjusting device; add solid salt into the draw liquid tank V-02 to adjust the draw The conductivity of the drawn liquid in the liquid tank V-02 reaches the preset value of 150-160ms / cm;

[0097] S2: Open the first valve 2WV1, the second valve 2WV2, the feed liquid pump P-01 and the feed liquid side bag filte...

Embodiment 3

[0106] This embodiment provides a method for multi-mode wastewater treatment by forward osmosis technology. The difference between this embodiment and Embodiment 2 is:

[0107] In step S3, the fourth valve 2WV4, the fifth valve 2WV5, the draw liquid pump P-02 and the draw liquid side bag filter F-02 are opened, and within the set time, the While the circulating feed liquid is concentrated on the feed liquid side of the forward osmosis membrane unit 1, the start and stop of the salt replenishment device is controlled by the draw liquid conductivity meter AIT02 to keep the draw liquid tank V-02 The conductivity of the internal draw solution remains unchanged until the set time is reached, and the wastewater treatment is completed;

[0108] Wherein, the method for controlling the start and stop of the salt replenishing device by the draw solution conductivity meter AIT02 includes: when the conductivity of the draw solution measured by the draw solution conductivity meter AIT02 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com