Efficient haw picker

A picker, high-efficiency technology, applied in the fields of agriculture and forestry, can solve the problem of low efficiency of hawthorn picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

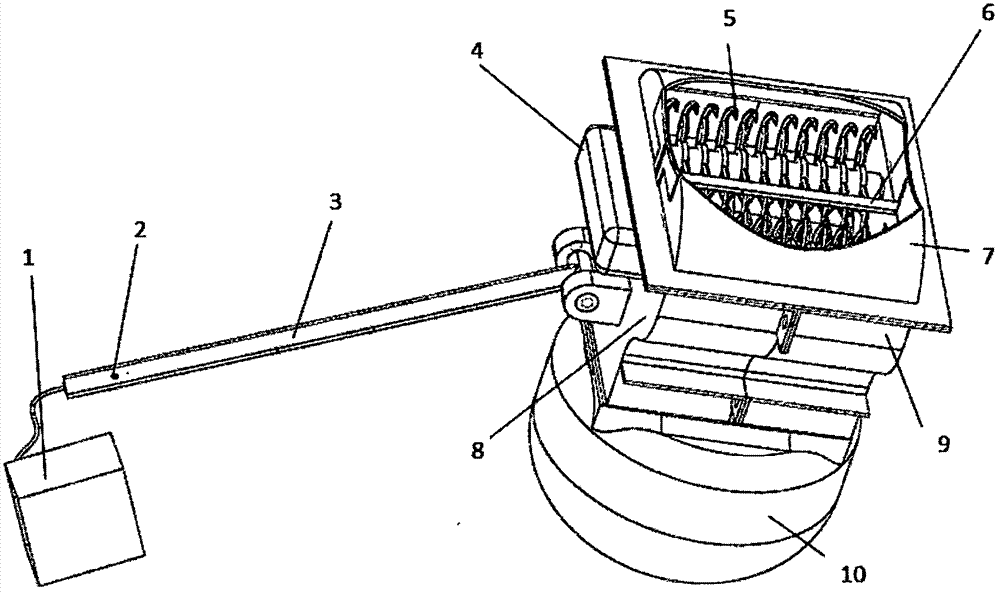

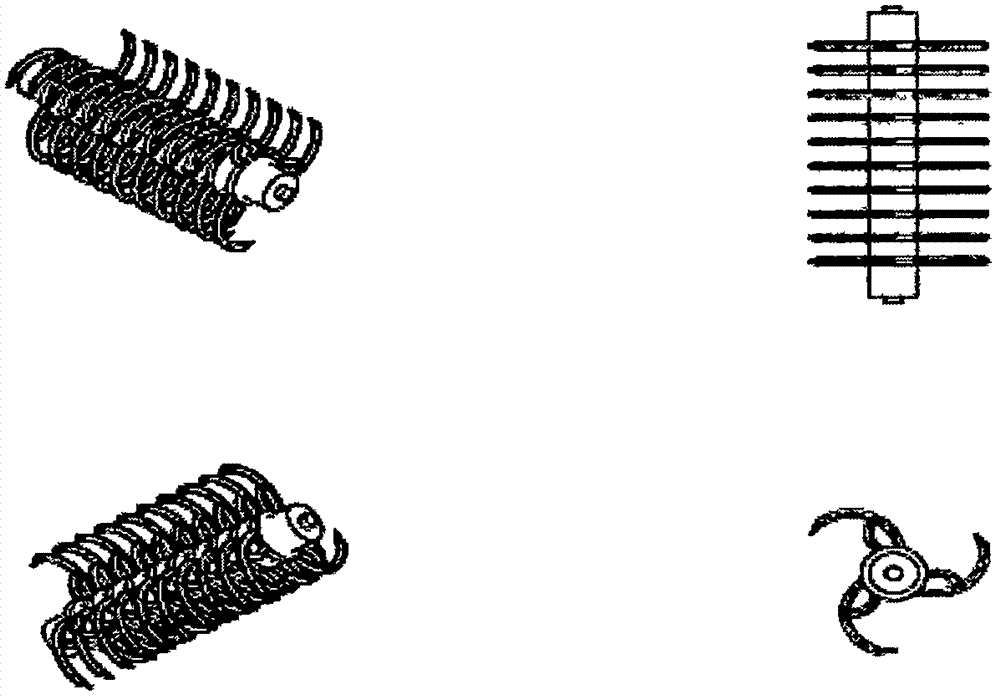

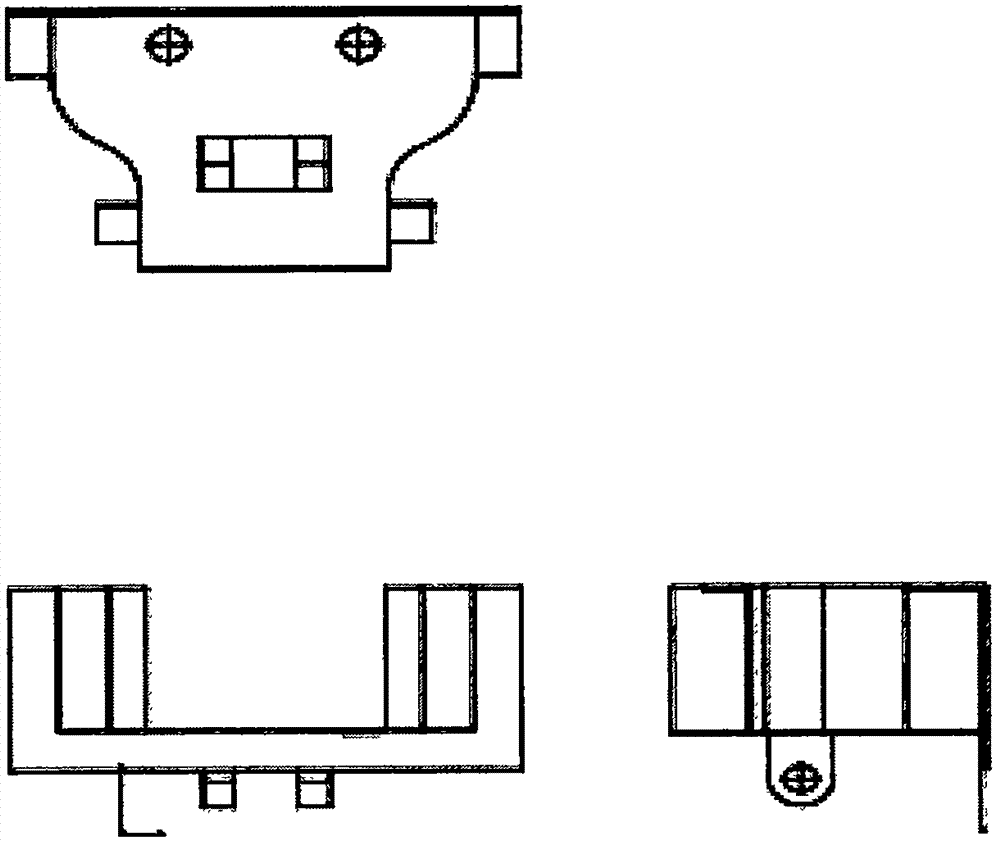

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. A high-efficiency hawthorn picker of the present invention includes: a battery 1, a control switch 2, a hand-held telescopic rod 3, a motor drive device 4, a pair of needle rollers 5, a separation strip 6, an upper half shell 7, and a rear half shell end 8, lower half shell front end 9 and fruit collection bag 10. When carrying out the picking operation, connect the connecting wire of the battery 1 with the lower end jack of the hand-held telescopic rod. After the hawthorn fruit is close to the picking mouth of the upper half shell 7, if attached Figure 4 As shown, the hawthorn is divided into left and right parts by the separation bar on the upper half of the shell, and the left and right needle rollers roll the hawthorn into the shell and complete the picking at the same time. The sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com