Breeding cage applicable to rubber production plant

A technology for production plants and breeding cages, applied in the field of chicken cages, which can solve the problems of affecting the survival rate and egg production performance of chickens, the poor appearance of eliminated chickens, and the susceptibility to sudden death. The effect of improving the rate of exercise and exercising the bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

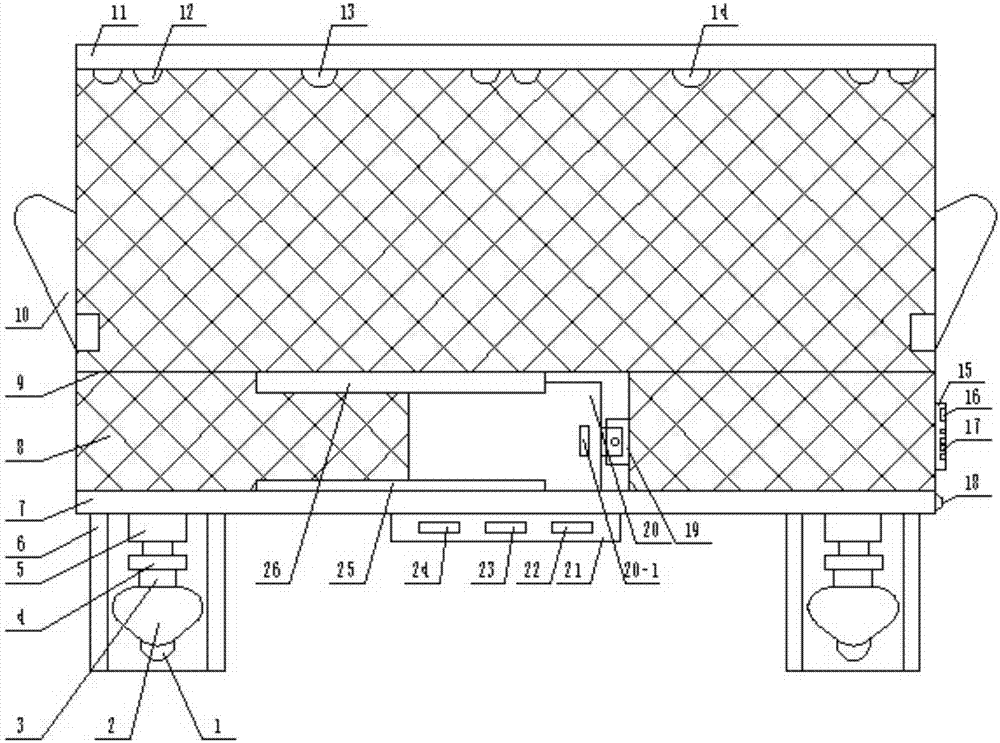

[0015] Combine below figure 1 To illustrate this embodiment, the present invention relates to a chicken cage, more specifically a breeding cage suitable for rubber production plants, including a universal wheel 1, a universal wheel bracket 2, a connecting piece 3, a connecting block 4, Hydraulic cylinder 5, bottom bracket 6, device main body 7, barbed wire 8, cross bar 9, food bin 10, top plate 11, lighting light 12, temperature detection sensor 13, humidity detection sensor 14, control panel 15, liquid crystal display 16, Control button 17, horn 18, lock plate 19, door 20, control box 21, solenoid valve 22, control chip 23, battery 24, sliding track Ⅰ 25 and sliding track Ⅱ 26, in order to prevent chickens from resting too much, on the barbed wire of the device Install the food bin, which contains vegetables and water. When the chicken wants to eat vegetables and drink water, the chicken needs to jump up, which can effectively exercise the chicken's bones, and at the same tim...

specific Embodiment approach 2

[0021] Combine below figure 1 This embodiment will be described. This embodiment will further describe the first embodiment. There are four universal wheels 1 , universal wheel brackets 2 , connectors 3 , connecting blocks 4 , hydraulic cylinders 5 and bottom brackets 6 .

specific Embodiment approach 3

[0022] Combine below figure 1 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the bottom bracket 6 is stainless steel, which has high strength, strong bearing capacity, and does not rust, and always maintains a good appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com