Inert gas auxiliary ejection lens mold ejection structure and ejection method

A technology of inert gas and lens molds, which is applied in household appliances, other household appliances, optical components, etc., can solve problems affecting the dimensional accuracy of injection molding products, cumbersome gas path settings, complex structures, etc., to achieve ingenious design, quality assurance, and guarantee The effect of optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

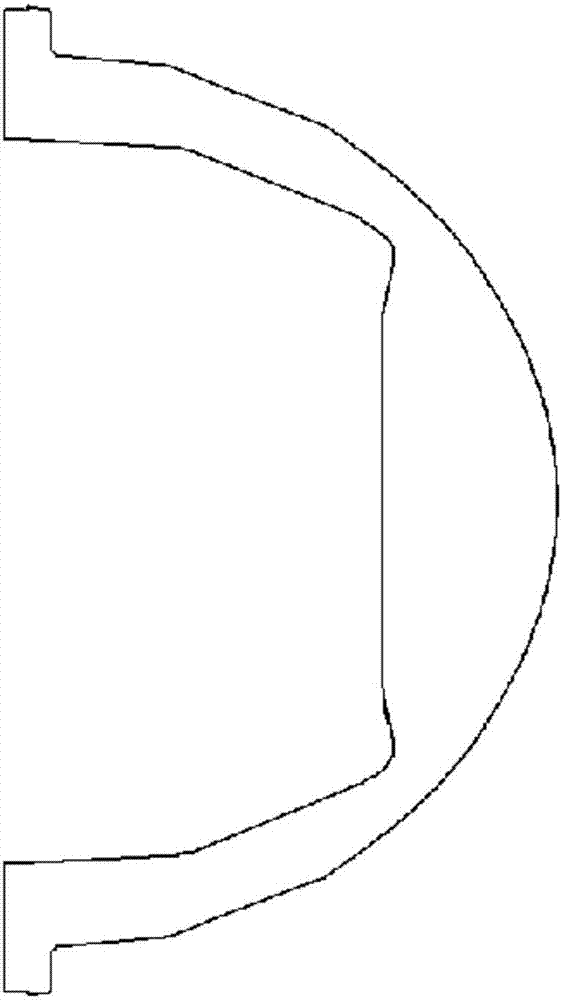

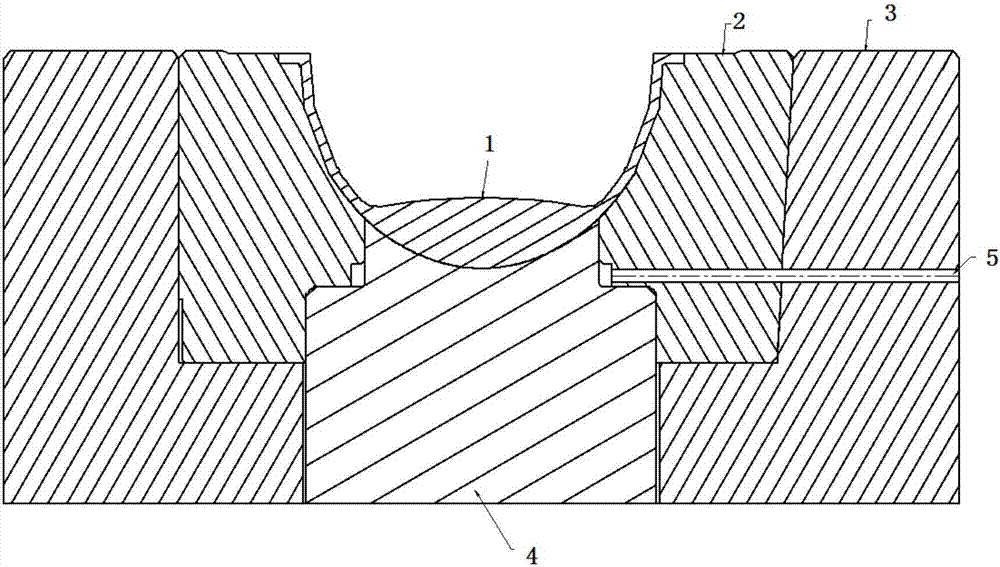

[0026] see Figure 1-6 , a lens mold ejection structure assisted by an inert gas, comprising a first movable mold insert 4 corresponding to the optical effective area of the lens, a second movable mold insert 2 corresponding to the peripheral position of the lens; the second movable mold insert 2 The mold insert 2 has an inert gas vent hole 5 communicating with the outside, and the inert gas vent hole 5 leads from the outside to the annular junction 6 of the second movable mold insert 2 and the first movable mold insert 4, and the annular The junction part 6 communicates with the bottom of the lens 1 through the annular gap 7 between the first movable mold insert 4 and the second movable mold insert 2; the size of the annular gap 7 is smaller than the size that the injection molding material can pass through, and larger than the inert gas pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com