An energy-saving integrated transformation method for an air compressor station in a power plant

A kind of air compressor, air compressor technology, applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problems of gas waste, low compression efficiency, unstable air supply pressure, etc., to reduce the probability of corrosion , High degree of automation, reducing the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

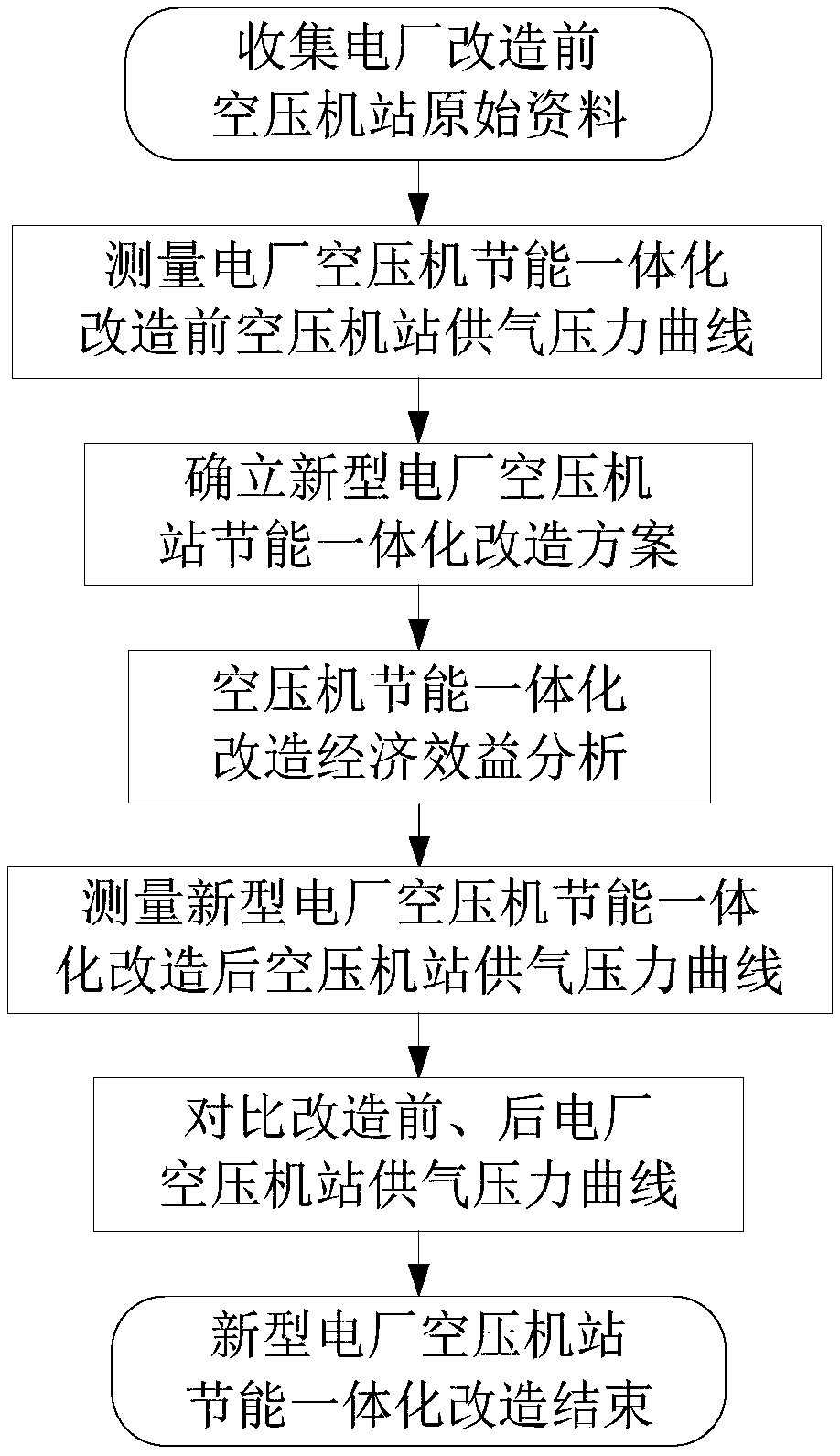

[0044] Such as figure 1 As shown, a kind of power plant air compressor station energy-saving integrated transformation method described in the present invention comprises the following steps:

[0045] 1) Collect the original data of the air compressor station before the transformation of the power plant, and enter step 2 after the collection is completed;

[0046] 2) Measure the air supply pressure curve of the air compressor station before the energy-saving integrated transformation of the air compressor in the power plant, and enter step 3);

[0047] 3) Establish an energy-saving integrated transformation plan for the air compressor station of the power plant, and enter step 4);

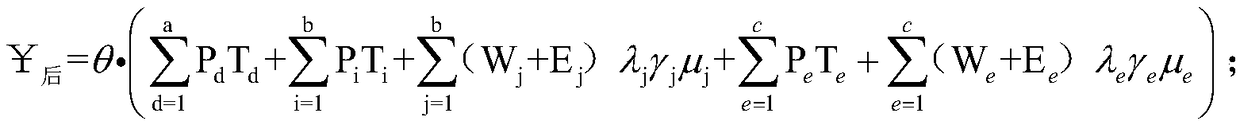

[0048] 4) Analyze the economic benefits of air compressor energy-saving integrated transformation, and enter step 5);

[0049] 5) Measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com