Automatic leveling method and leveling device for 3D print

An automatic leveling and 3D printing technology, applied in the field of 3D printing, can solve the problems of tilting printing platform and large printing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

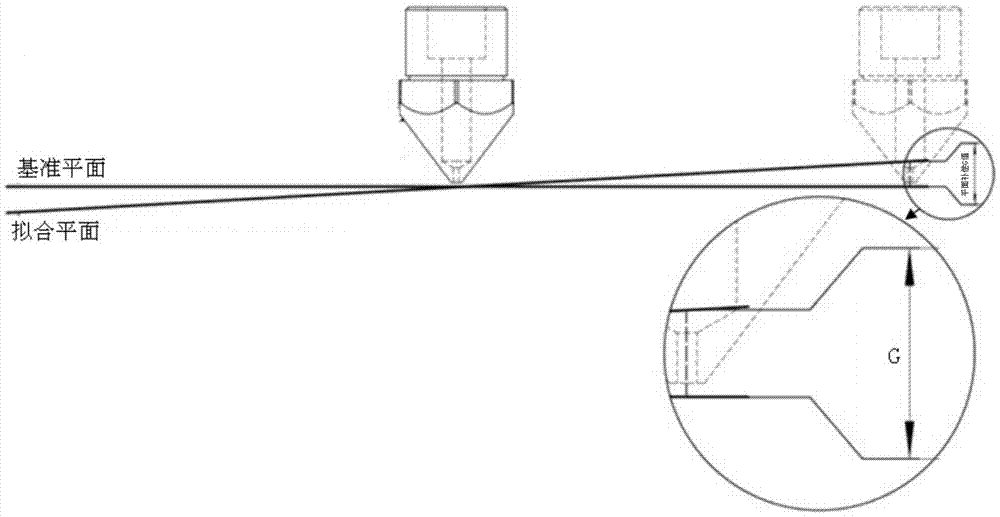

[0048] The automatic leveling method applied to 3D printing in this application refers to constructing the fitting plane between the datum plane and the printing platform first, and the fitting plane is the real plane of the printing platform, and then calculates the position and datum of each point on the real plane through a certain algorithm. The error value between the planes, so as to obtain the compensation value required by the print head on the z-axis. Including the following steps:

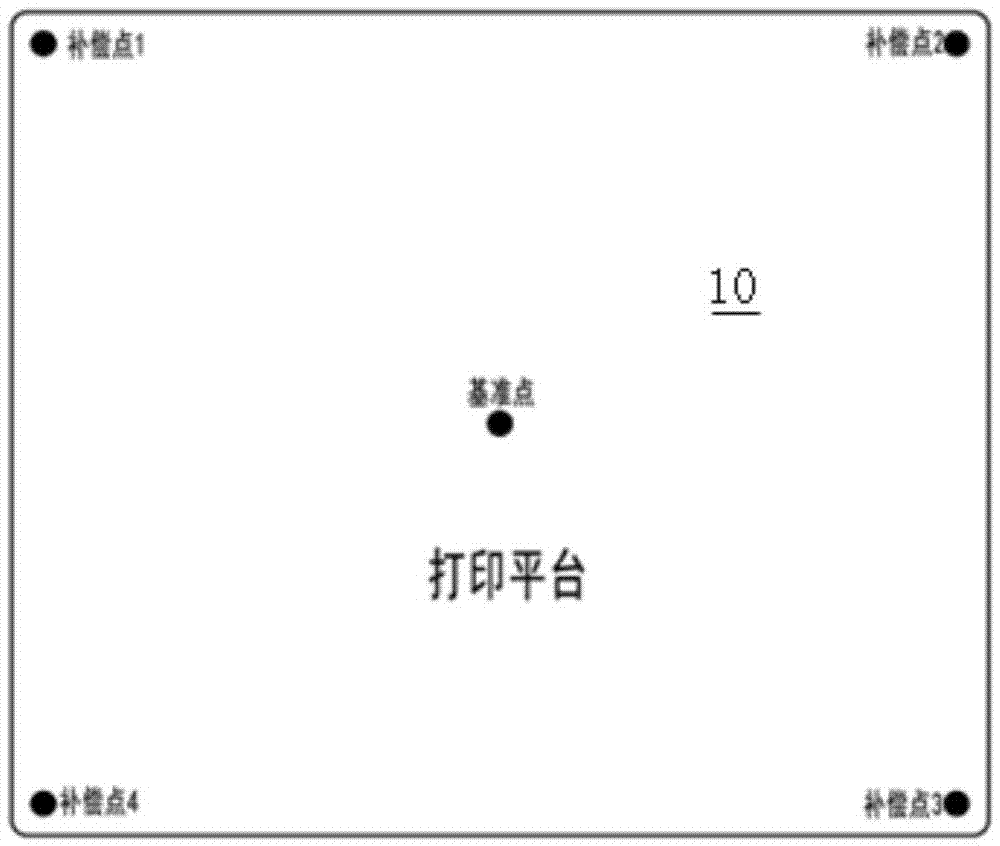

[0049] S11: Obtain the three-dimensional coordinate values of a reference point and four compensation points on the printing platform.

[0050] Such as figure 1 As shown, this step refers to detecting the three-dimensional coordinate values of a reference point and four compensation points on the printing platform through the detection unit provided on the print head, and the detection unit is specifically a tact switch or a light detection instrument. include:

[0051] The detecti...

Embodiment 2

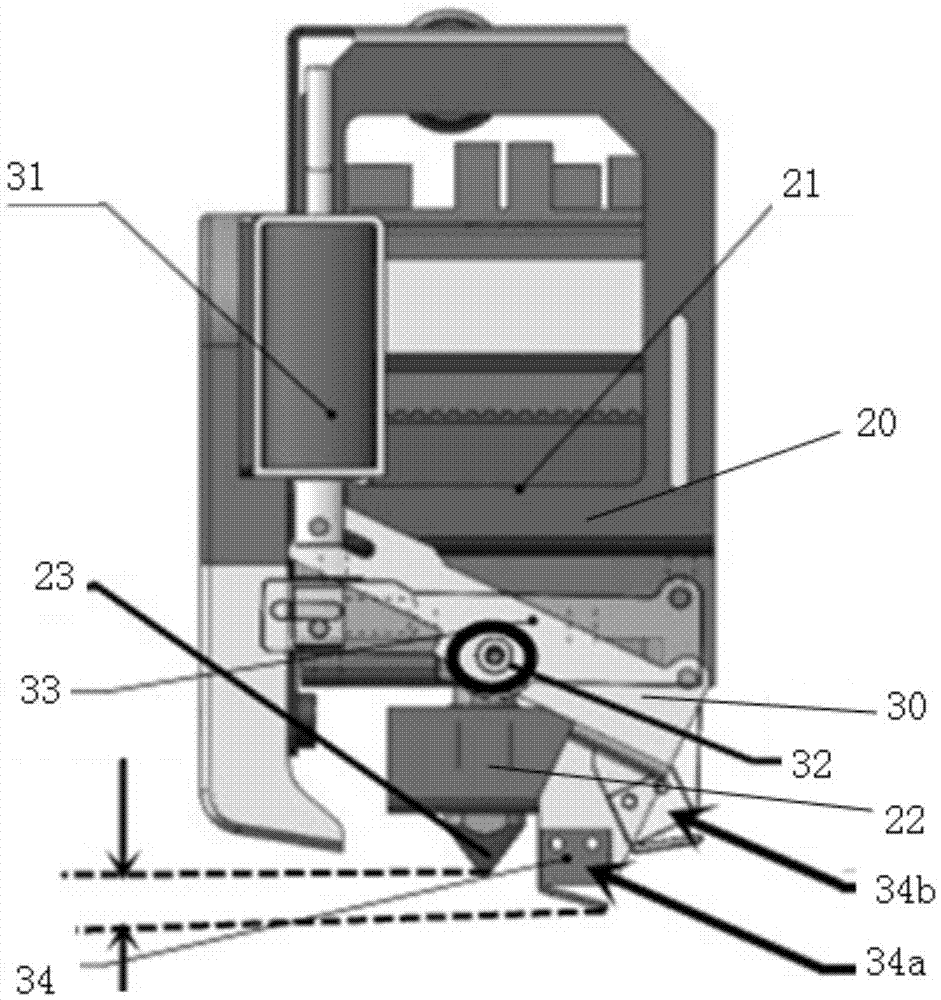

[0067] Such as figure 1 , image 3 As shown, the automatic leveling system applied to 3D printing in this application includes a printing platform 10, a printing head 20 for ejecting printing materials, a detection unit 30, and a calculation control unit (not shown). The detection unit 30 is installed on the print head 20, and the print head 20 includes an extrusion head holder 21, an extrusion head 22 installed at the lower end of the extrusion head holder 21, and an extrusion head located on the extrusion head holder 21. Out of the nozzle 23 at the bottom of the head 22. The detection unit 30 includes an electromagnet 31 installed on the print head 22, a fulcrum 32, a rotating arm 33 rotatably installed on the fulcrum 32 and one end connected to the electromagnet 31, and an arm 33 installed on the fulcrum 32. The tact switch 34 at the other end of the rotating arm 33 . During leveling detection, the electromagnet 21 is energized, and the light touch switch 34a of the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com