Pressure Welding Contact Having A Bellows Type Terminal And Pressure Welding Connector

A technology for crimping contacts and contact connections, used in multi-conductor connectors, connections, conductive connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

[0056] [Structure of crimping contacts]

[0057] First, the structure of a crimp contact according to one embodiment of the present invention will be described.

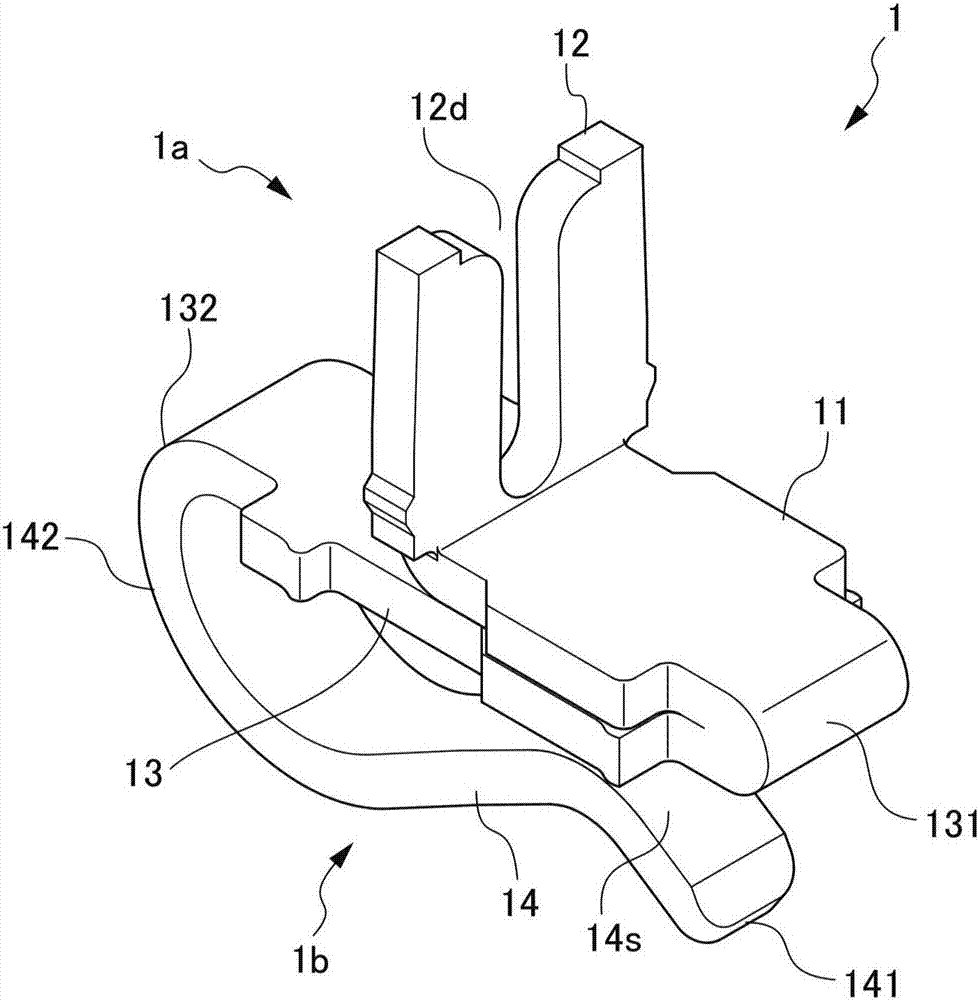

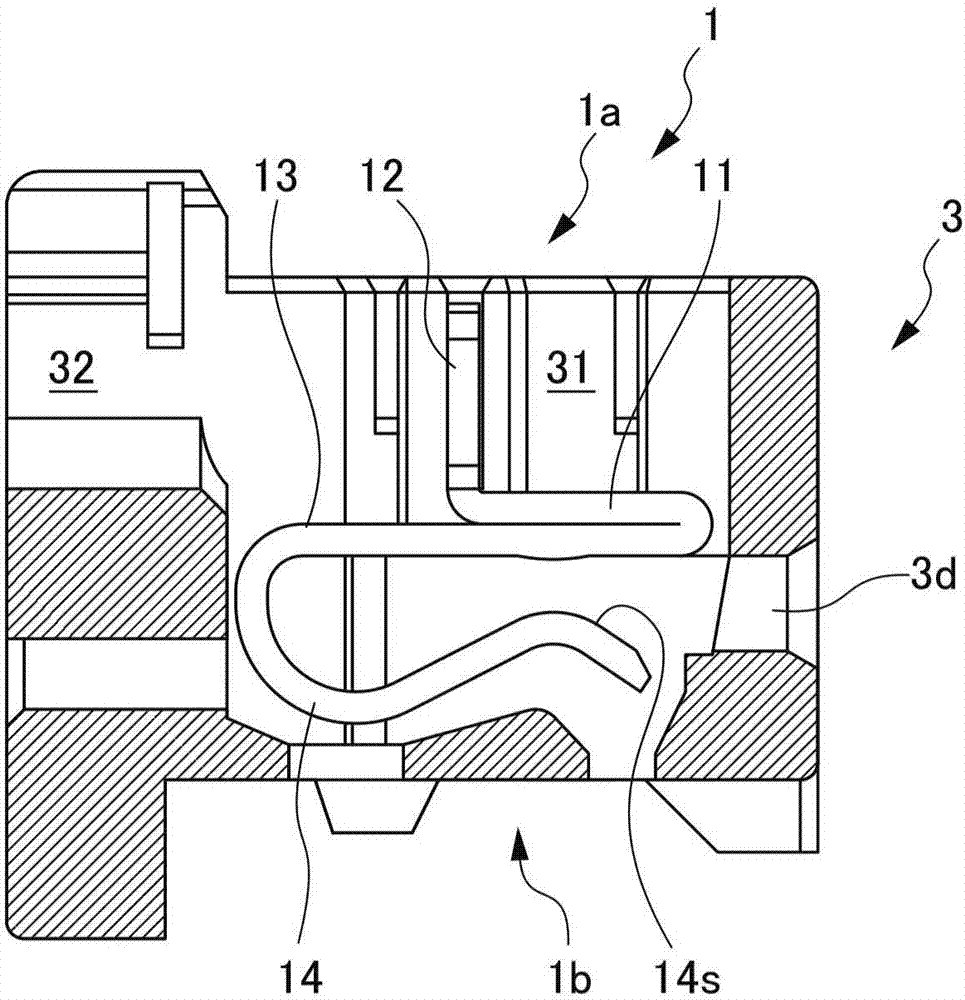

[0058] figure 1 It is a perspective view showing the structure of the crimping contact which concerns on one Embodiment of this invention. figure 2 It is a right side view showing the structure of the crimping contact according to the embodiment, and shows a state in which the crimping contact is attached to the inside of the first housing.

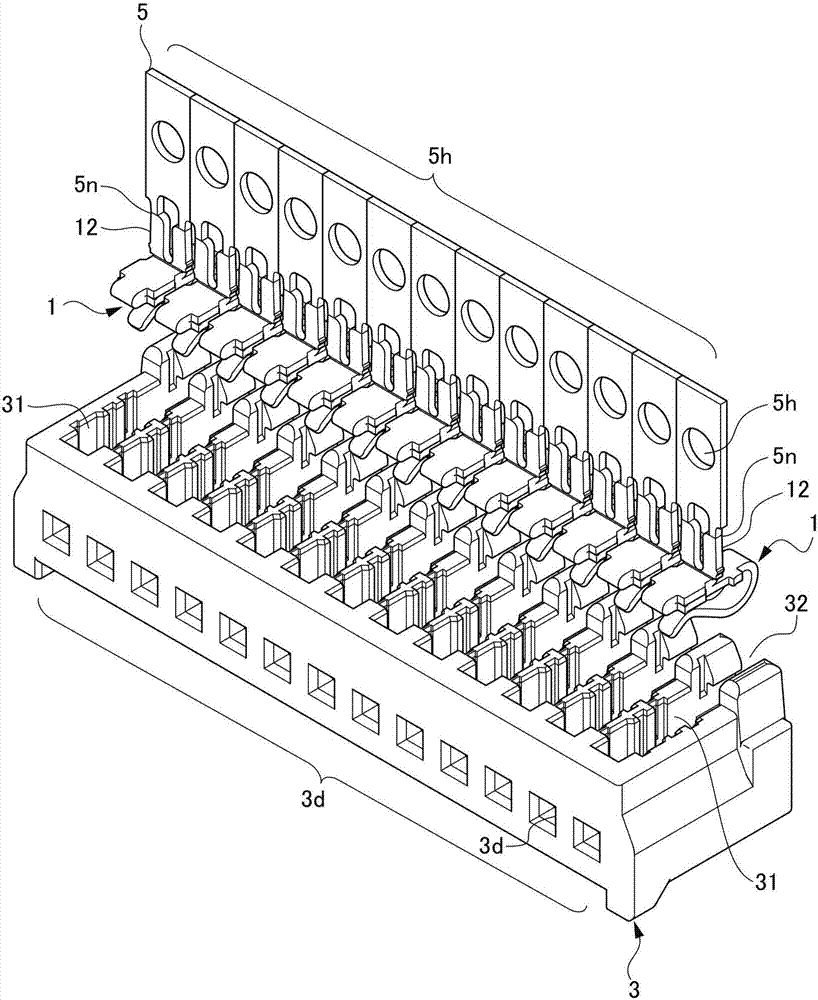

[0059] image 3 It is a perspective view of a contact carrier to which the crimping contacts of the above-mentioned embodiment are connected, and shows a state before the crimping contacts are attached to the first housing arranged to face the contact carrier.

[0060] Figure 4 It is a front view of a contact carrier to which the crimping contacts of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com