Intelligent full-automatic micro-drawing machine

A fully automatic, micro-drawing machine technology, applied in the mechanical field, can solve problems such as low intelligence, uneven operation such as drooping or tightness, and inability to monitor the running speed of copper wires in real time, etc., to achieve high intelligence, micro-drawing Uniform and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: an intelligent automatic micro-drawing machine

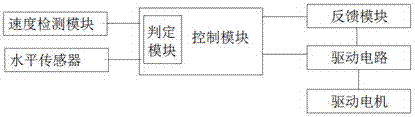

[0020] see figure 1 , used for micro-drawing of copper wire, including chassis, wire mechanism, oil supply mechanism, wire inlet mechanism, micro-pulling mechanism, outlet mechanism and driving mechanism.

[0021] Wherein, the wire mechanism includes a guide plate and a guide groove, and the copper wire is arranged in the guide groove for guiding the copper wire to be processed to the wire inlet of the wire inlet mechanism.

[0022] The wire inlet mechanism is arranged on one side of the chassis along the width direction, and is used to introduce the copper wire to be stretched into the micro-drawing mechanism; the wire outlet mechanism is arranged on the other side of the chassis along the width direction, It is used to lead out the copper wire stretched by the micro-drawing mechanism.

[0023] Described micro-pull mechanism comprises a micro-pull unit and a micro-pull control unit, and described micro-pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com