A kind of driving device of printing head and thermal printer thereof

A driving device and print head technology, applied in printing and other directions, can solve problems such as inability to adjust, difficulty in taking out the carbon ribbon, and inability to reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

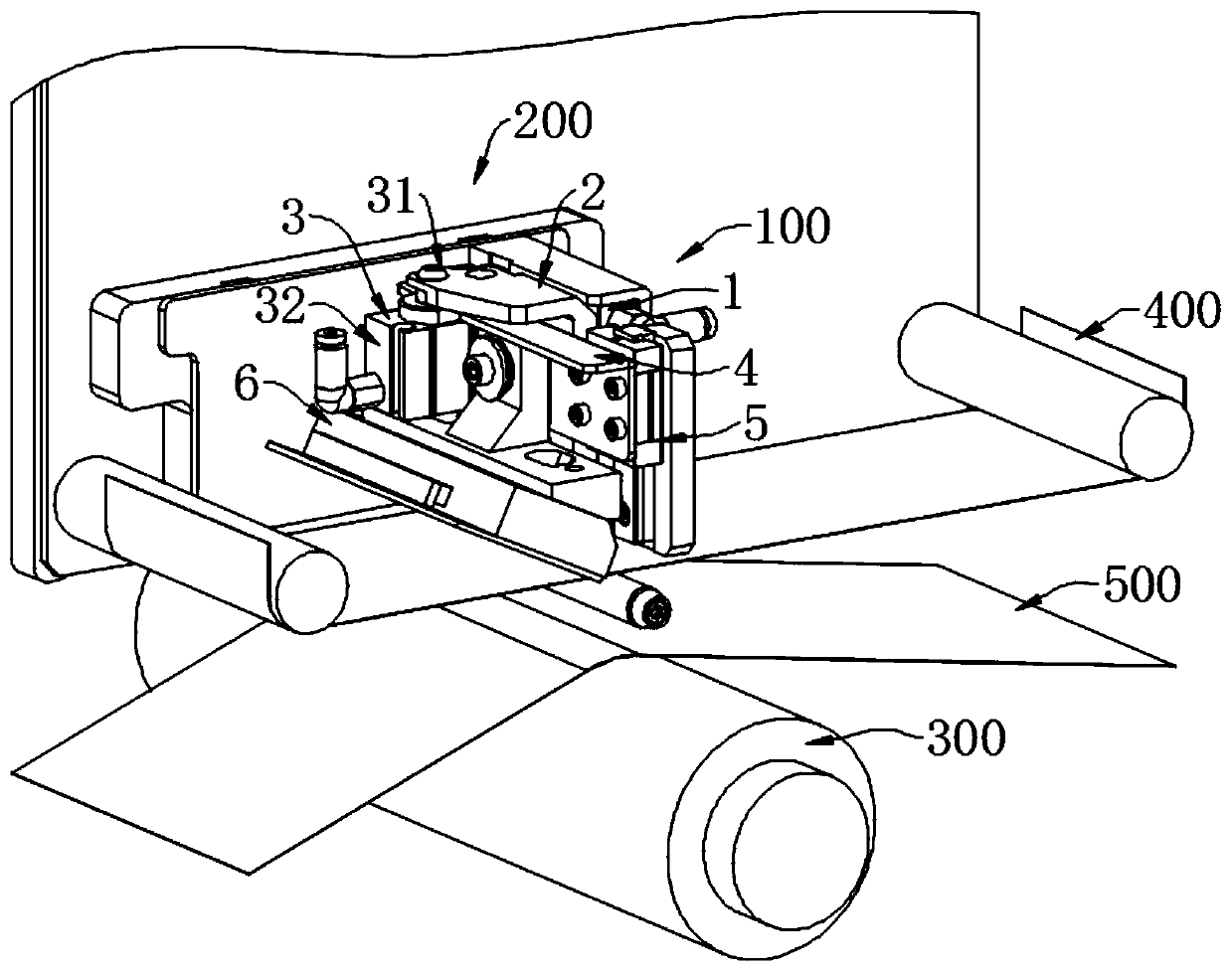

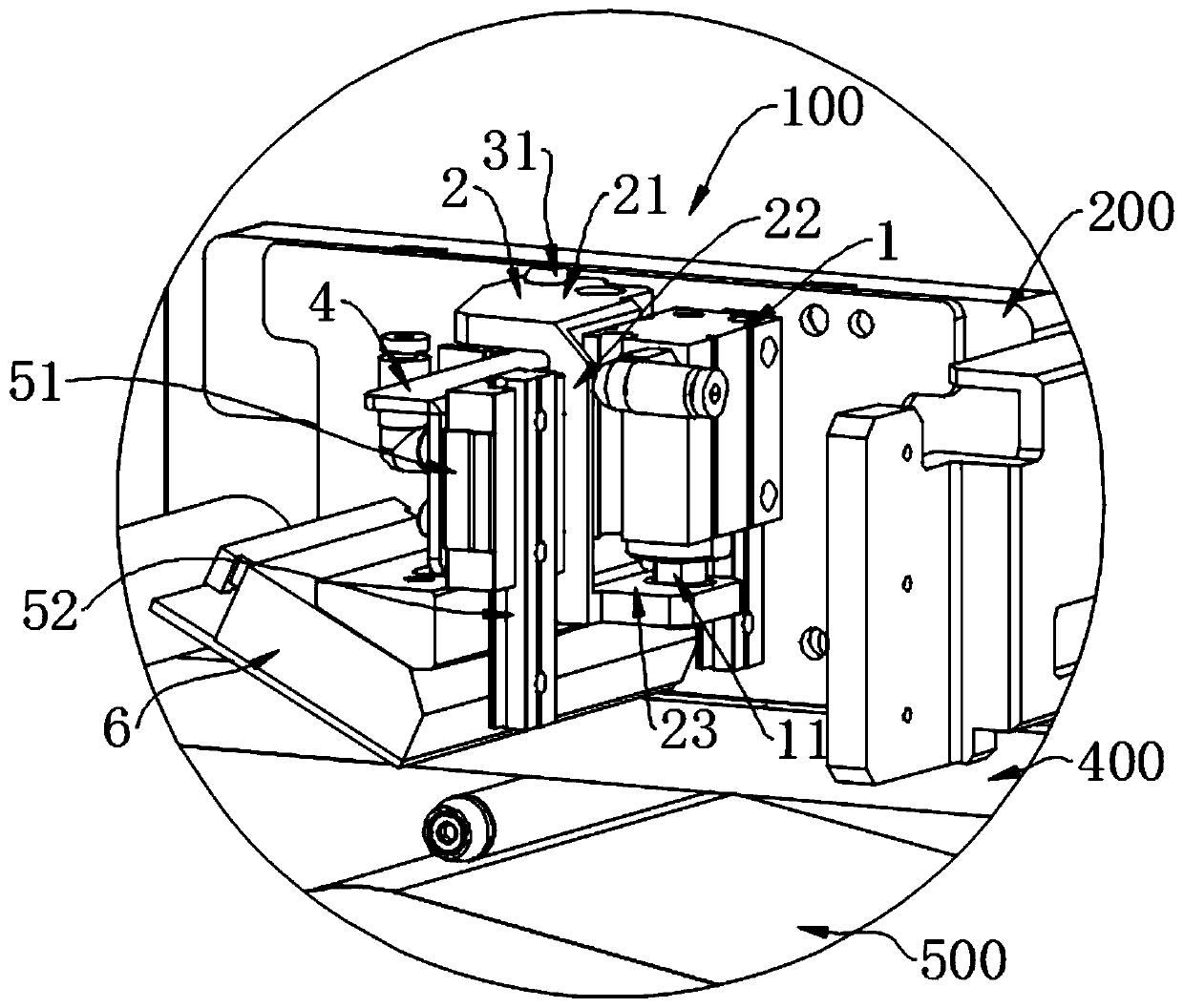

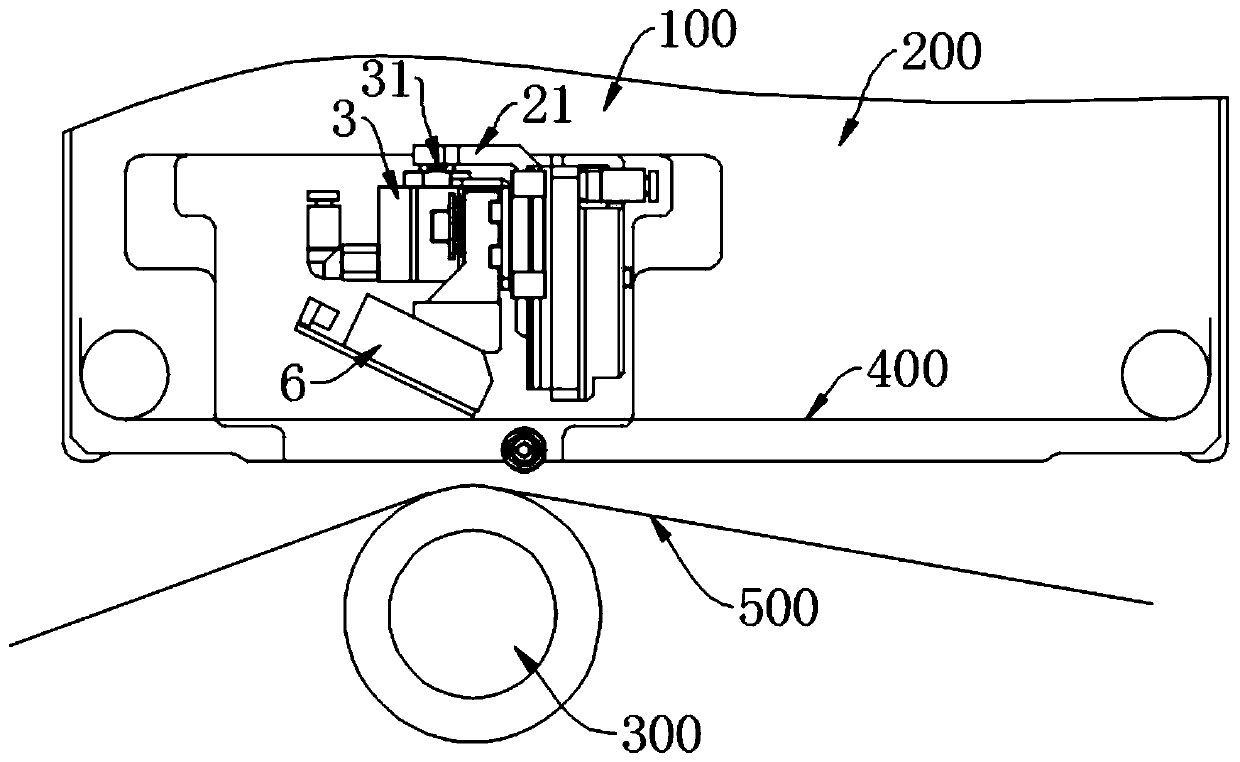

[0034] see Figure 1 to Figure 5 As shown, the driving device 100 includes a first driving member 1, a connecting bracket 2 and a second driving member 3, the first driving member 1 is arranged on the printer base 200, and the first driving member 1 has a first output shaft 11. The connecting bracket 2 is drivingly connected with the first output shaft 11 and moves back and forth relative to the position to be printed. The second drive member 3 has a second output shaft 31 and a first cylinder body 32, the second output shaft 31 is fixedly connected to the connecting bracket 2, and the second output shaft 31 expands and contracts so that the first cylinder The body 32 reciprocates between the position to be printed and the printing position; the print head 6 has a motion state of moving with the first cylinder body 32 .

[0035]The present invention connects the two driving parts to the connecting bracket 2, the print head 6 is connected to the second driving part 3, and the...

Embodiment 2

[0042] see Figure 1 to Figure 5 As shown, a thermal printer uses the driving device 100 in Embodiment 1, the printer also includes a printer base 200, a print head 6 and a rubber roller 300, and the driving device 100 is arranged on the printer base 200, The recording medium 500 passes between the printing head 6 and the rubber roller 300 , the printing head 6 is arranged on the driving device 100 , and the printing head 6 presses the carbon ribbon 400 against the recording medium 500 .

[0043] The printing head 6 moves to the position to be printed by the first driving member 1, and moves to the printing position by the second driving member 3, the rubber roller 300 is perpendicular to the moving direction of the printing head 6, and the The print head 6 is in line contact with the rubber roller 300 at the front of the rubber roller 300 . That is, the print head 6 is in contact with the rubber roller 300 on the busbar at the top of the rubber roller 300 to avoid the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com