A multi-head automatic filling system and filling method

An automatic filling and filling technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as low degree of automation, waxing of equipment parts, and reduced filling efficiency, so as to ensure filling quality and operation High efficiency and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

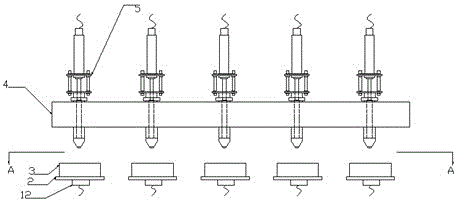

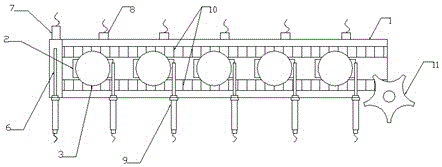

[0032] Such as Figure 1-4 As shown, a multi-head automatic filling system includes an assembly line 1 and five filling mechanisms arranged on the assembly line 1 in sequence. The filling mechanism includes a filling device 5, a filling platform 2 and a lever mechanism. The bottom surface of the filling platform is provided with a weight sensor 12 for instant detection of the weight of the tank body 3 on the filling platform 2; the filling device 5 is arranged above the filling platform 2 for filling the wax liquid; The mechanism is arranged on the side of the filling platform 2 for positioning the tank body 3 on the filling platform 2 . The assembly line 1 also includes lifting conveyor chains 10 symmetrically arranged on both sides of the filling platform. When the lifting conveyor chain 10 rises, the tank body 3 can run together with the lifting conveyor chain 19. When the lifting conveyor chain 10 descends , the tank body 3 stays on the filling platform 2. The multi-hea...

Embodiment 2

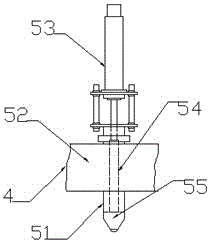

[0047] The rest is the same as that of Embodiment 2, except that the multi-head automatic filling system includes ten filling mechanisms sequentially arranged on the assembly line. The filling device 5 of the filling mechanism includes a wax filling chamber 52 , a filling piston 55 , a connecting rod 54 and a connecting rod driving cylinder 53 , and each wax filling chamber 52 is connected to the wax delivery pipe 4 respectively.

Embodiment 3

[0049] All the other are identical with embodiment 1, and difference is, as Figure 5 As shown in the figure, the connection between the conical bottom of the filling piston and the connecting rod is provided with a universal joint. When the filling piston slides in the filling mouth, even if the axis of the filling piston and the filling mouth deviates, the filling piston still remains under the action of the universal joint. It can maintain a tight connection with the filling mouth and effectively block the filling mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com