A binding device for a brake clutch plate

A clutch, strapping technology, applied in the direction of strapping materials, parts of strapping machinery, etc., can solve the problems of low safety, slow strapping speed, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

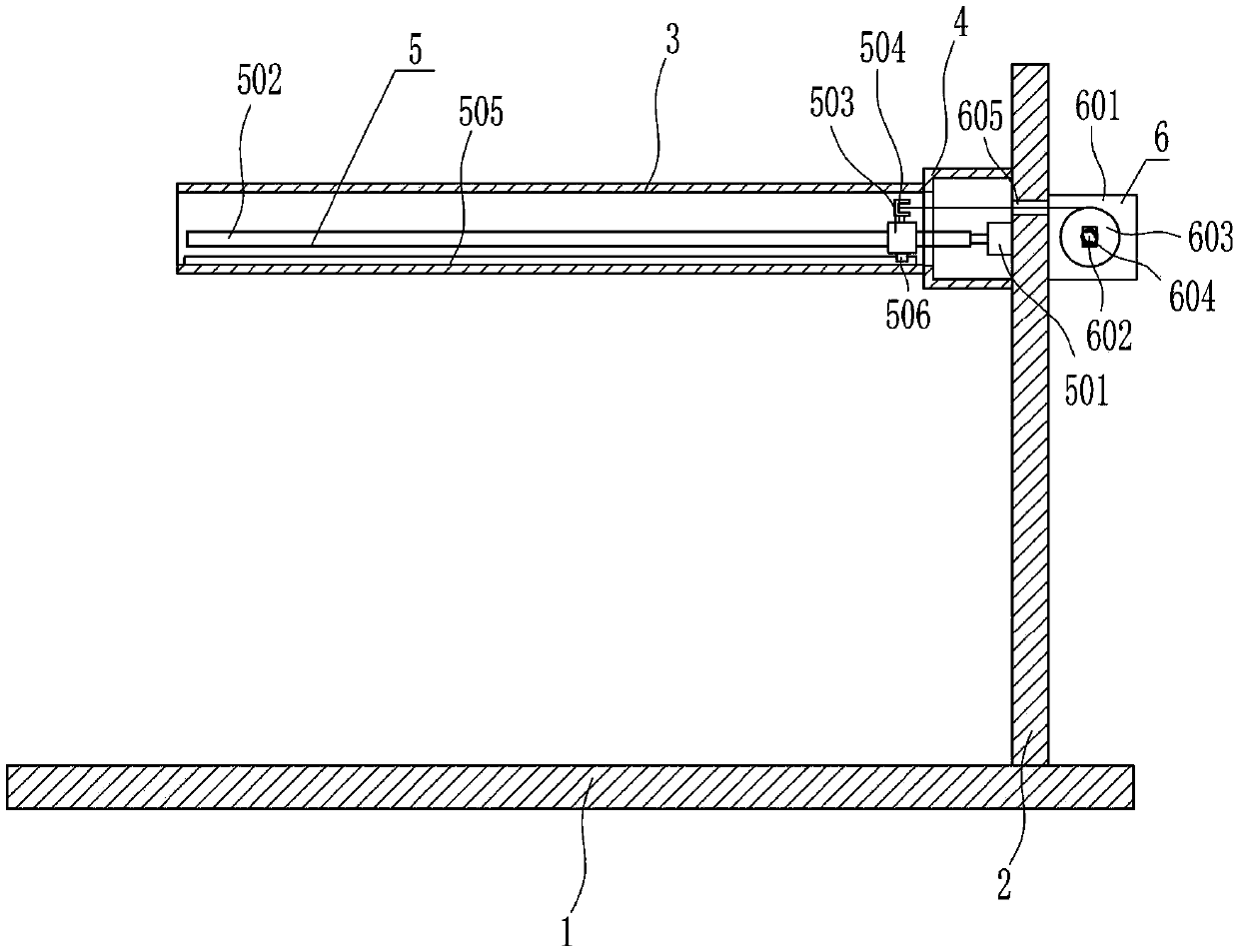

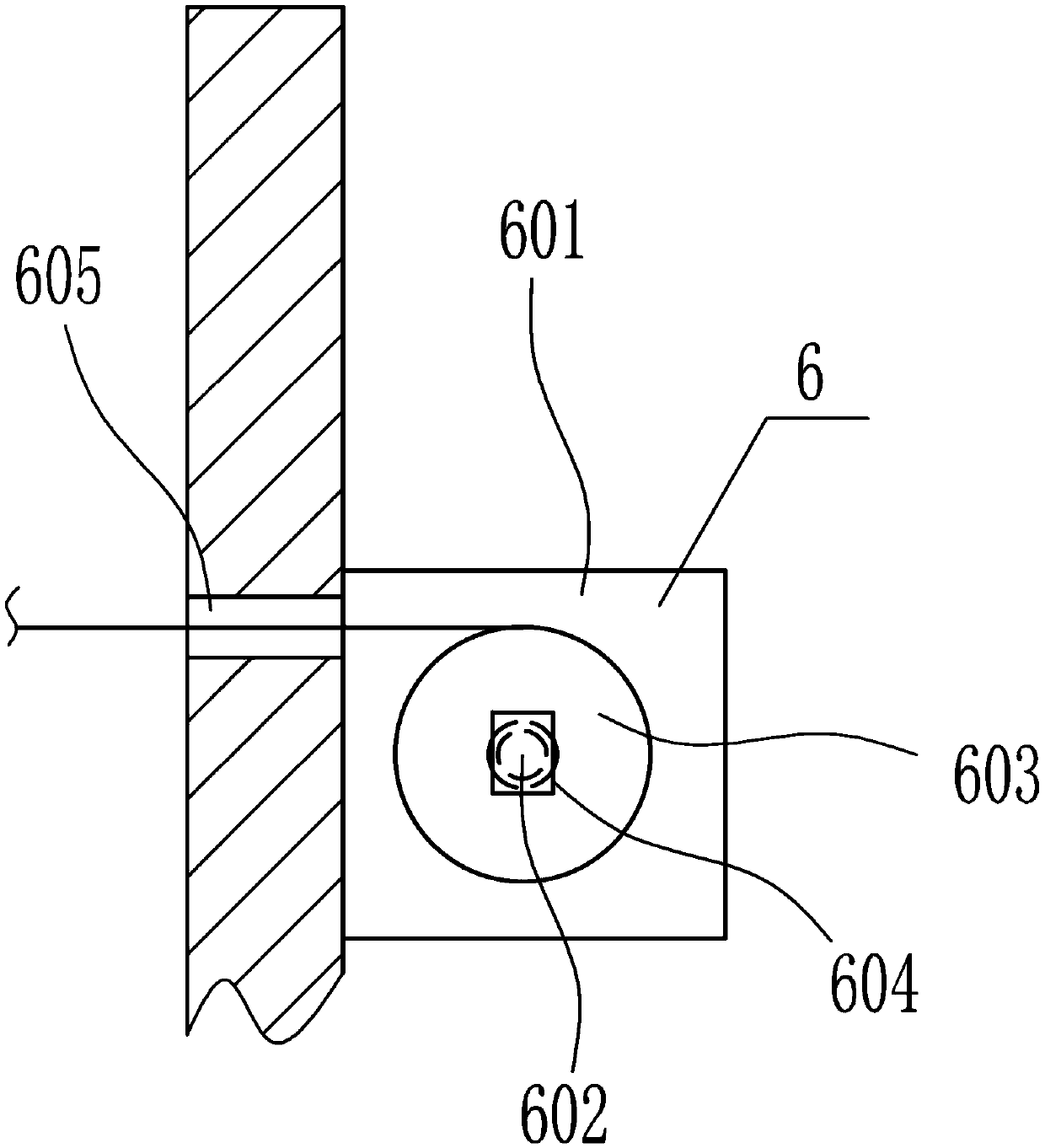

[0037] A binding device for a brake clutch plate, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a box body 3, an n-shaped frame 4, a left and right moving device 5 and a strap fixing device 6. The support plate 2 is welded on the right side of the top of the base plate 1, and the upper part of the left side of the support plate 2 is The n-shaped frame 4 is welded, and the left side of the n-shaped frame 4 has an opening. The left side of the n-shaped frame 4 is welded with a box body 3. As for the device 5, a strap fixing device 6 is provided on the upper right side of the support plate 2.

Embodiment 2

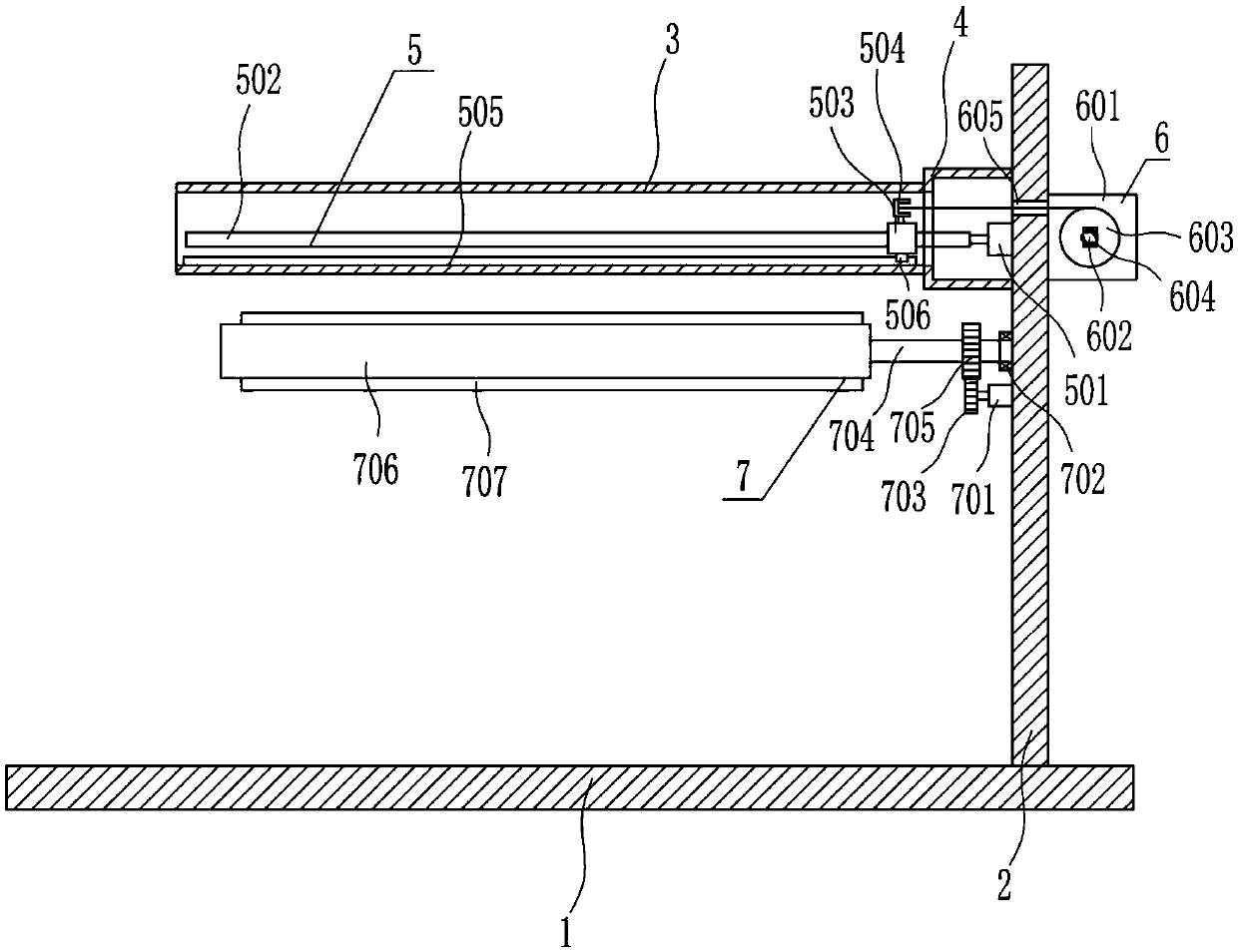

[0039] A binding device for a brake clutch plate, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a box body 3, an n-shaped frame 4, a left and right moving device 5 and a strap fixing device 6. The support plate 2 is welded on the right side of the top of the base plate 1, and the upper part of the left side of the support plate 2 is The n-shaped frame 4 is welded, and the left side of the n-shaped frame 4 has an opening. The left side of the n-shaped frame 4 is welded with a box body 3. As for the device 5, a strap fixing device 6 is provided on the upper right side of the support plate 2.

[0040] The left and right moving device 5 includes a first motor 501, a screw rod 502, a nut 503, a thumb cylinder 504, a first slide rail 505 and a first slide block 506, and the first motor 501 is connected with the top of the left side of the support plate 2 by bolts. A motor 501 is located in the n-type frame 4, the output shaft of the first motor 501 is...

Embodiment 3

[0042] A binding device for a brake clutch plate, such as Figure 1-6 As shown, it includes a base plate 1, a support plate 2, a box body 3, an n-shaped frame 4, a left and right moving device 5 and a strap fixing device 6. The support plate 2 is welded on the right side of the top of the base plate 1, and the upper part of the left side of the support plate 2 is The n-shaped frame 4 is welded, and the left side of the n-shaped frame 4 has an opening. The left side of the n-shaped frame 4 is welded with a box body 3. As for the device 5, a strap fixing device 6 is provided on the upper right side of the support plate 2.

[0043] The left and right moving device 5 includes a first motor 501, a screw rod 502, a nut 503, a thumb cylinder 504, a first slide rail 505 and a first slide block 506, and the first motor 501 is connected with the top of the left side of the support plate 2 by bolts. A motor 501 is located in the n-type frame 4, the output shaft of the first motor 501 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com