Combined creel of dyeing bobbin yarn and warp beam yarn, zipper, cloth tape and rope belt

A technology for package yarn and yarn, applied in the field of dyeing machinery, can solve the problems of unsatisfactory yarn dyeing and finishing quality, difficulty in precise control of fluid pressure, waste of process time, etc., achieving simple structure, reducing fluid energy loss and improving energy efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above content has fully described the present invention, and the present invention will be further described below in conjunction with specific examples, but the implementation and protection of the present invention are not limited thereto.

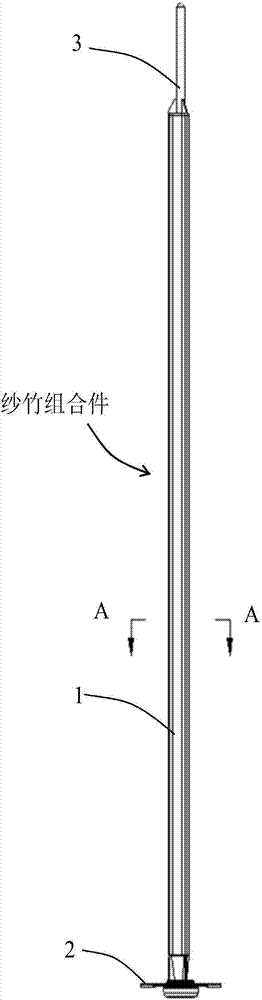

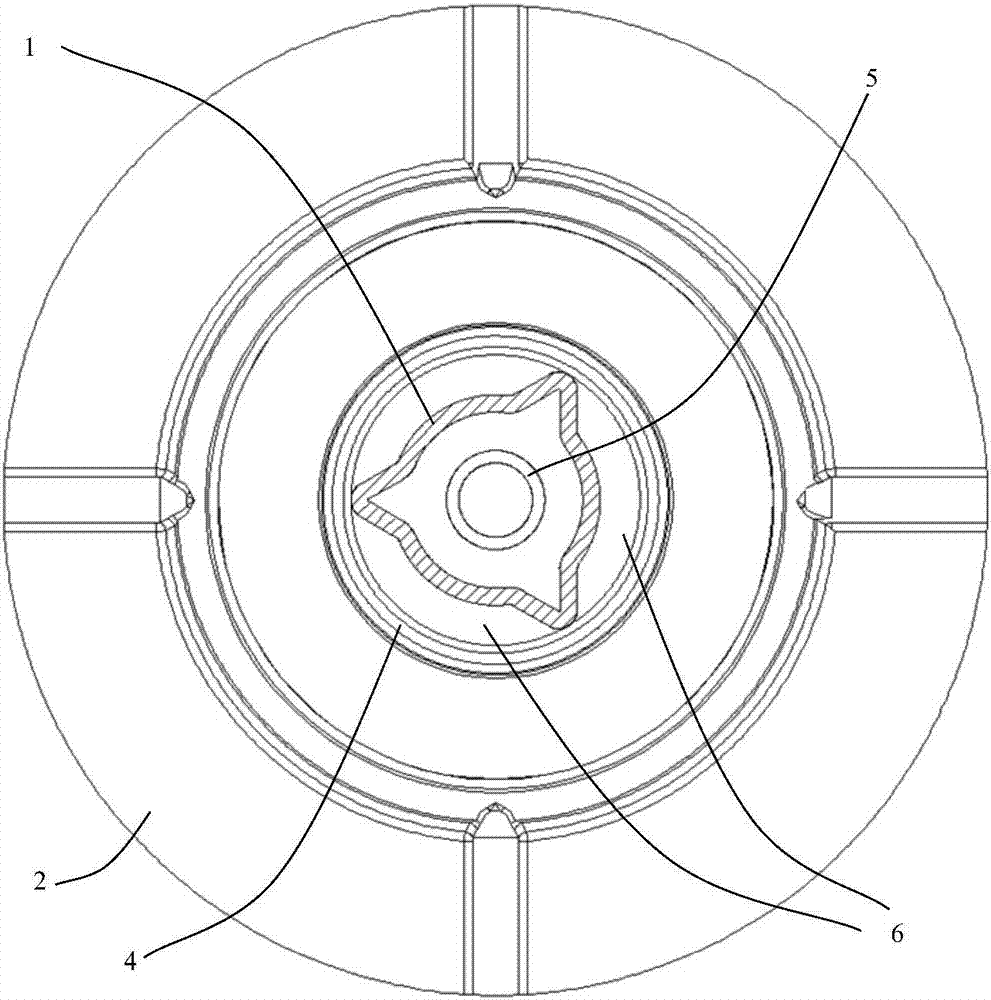

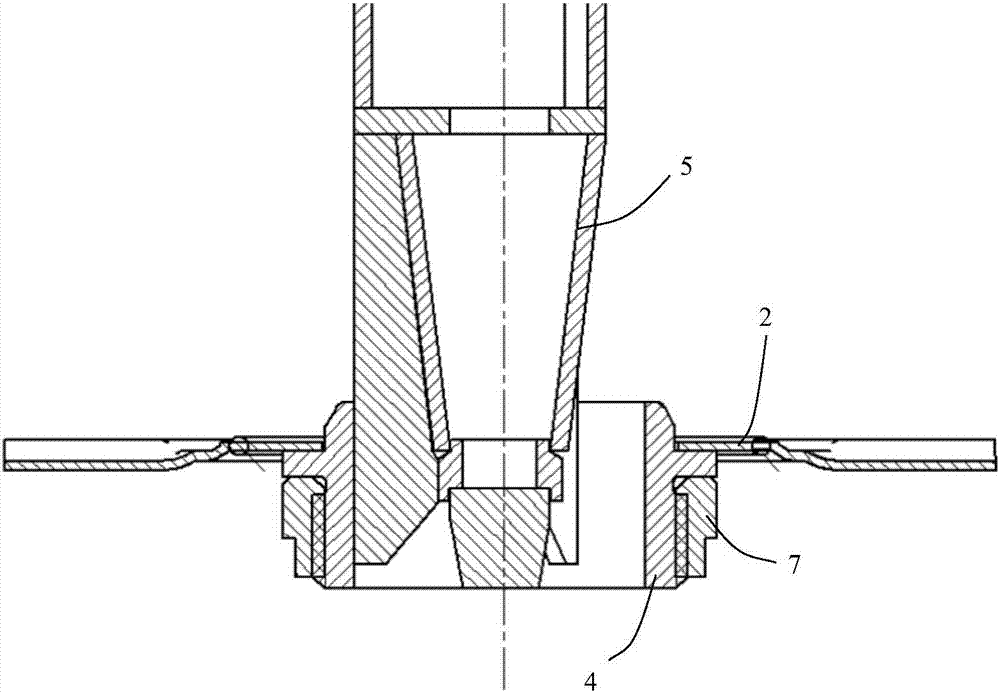

[0032] like Figure 1~Figure 5 As shown, a combined creel suitable for dyeing package yarn and warp beam yarn, zipper, cloth tape and rope belt mainly includes water drum 1, bottom plate 2, stud 3, upper tooth holder 4, water drum Head 5, runner 6, lower tooth seat 7 and other components.

[0033] like Image 6 , the water drum 1 is composed of a cylinder 11 and a plurality of raised ribs 12 formed on the wall of the cylinder; a plurality of raised ribs 12 are evenly distributed on the cylinder 11; the surface of the cylinder 11 is smooth, Via holes are not provided.

[0034] The upper end of the water drum 1 is coaxially connected with the stud 3, and the stud 3 is also used as the upper head of the water drum 1; the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com