Novel plastic air pump machine core

A plastic and air pump technology is applied in the field of new plastic air pump cores, which can solve the problems of difficulty in realizing one air pump for one vehicle, inconvenient use, and unfavorable promotion, and achieves the effect of being beneficial to popularization and use, reducing production costs and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

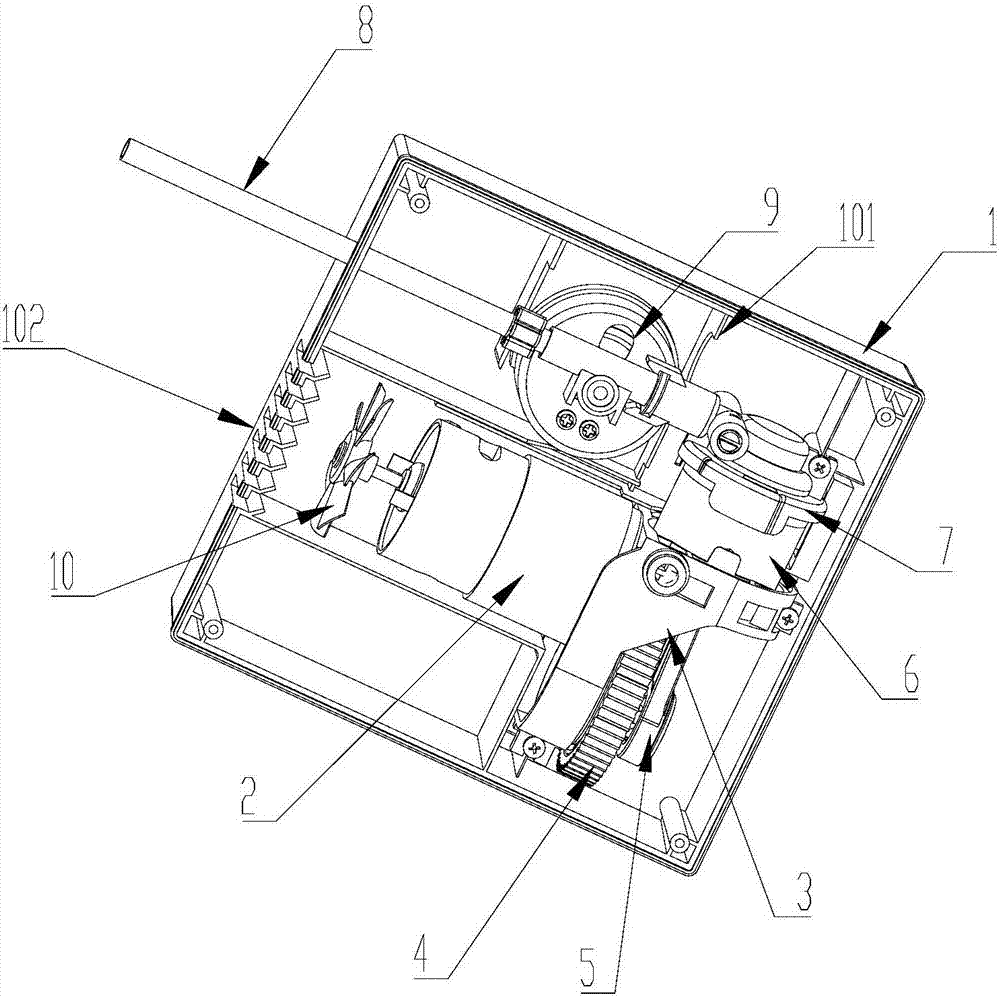

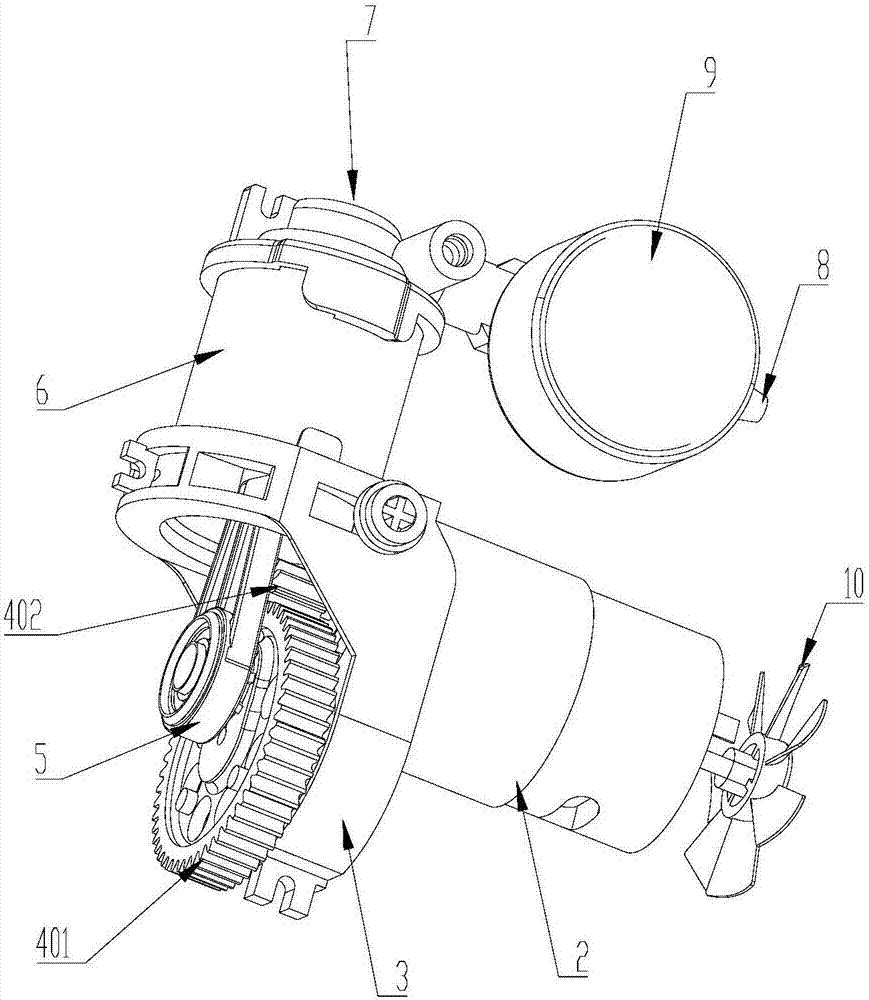

[0033] This embodiment provides a novel plastic air pump core, such as Figure 1 to Figure 2 As shown, it includes a plastic cylinder 6, a plastic piston (not shown), a plastic output disc 7 and a power mechanism, and the power mechanism includes a plastic gear 4, a plastic rocker arm 5, and a motor 2;

[0034] The air pump core further includes a plastic bracket 3 for fixing and supporting the motor 2, the plastic gear 4, the plastic rocker arm 5, and the plastic cylinder 6;

[0035] The plastic output disc 7 is fixedly connected to the plastic cylinder 6 through a rotating buckle, and the plastic bracket 3 is fixedly connected to the motor 2 and the plastic cylinder 6 through a rotating buckle;

[0036] The core of the new plastic air pump is integrally arranged in a plastic shell 1, and the plastic shell 1 is provided with a card slot 101 matching with the plastic cylinder 6, the plastic output plate 7, the plastic bracket 3, the plastic rocker arm 5, the plastic gear 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com