Immersed type electrode steam boiler

A steam boiler and submerged technology, applied in the field of submerged electrode steam boilers, can solve the problems of low energy utilization efficiency, dry burning, and untimely replenishment of water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

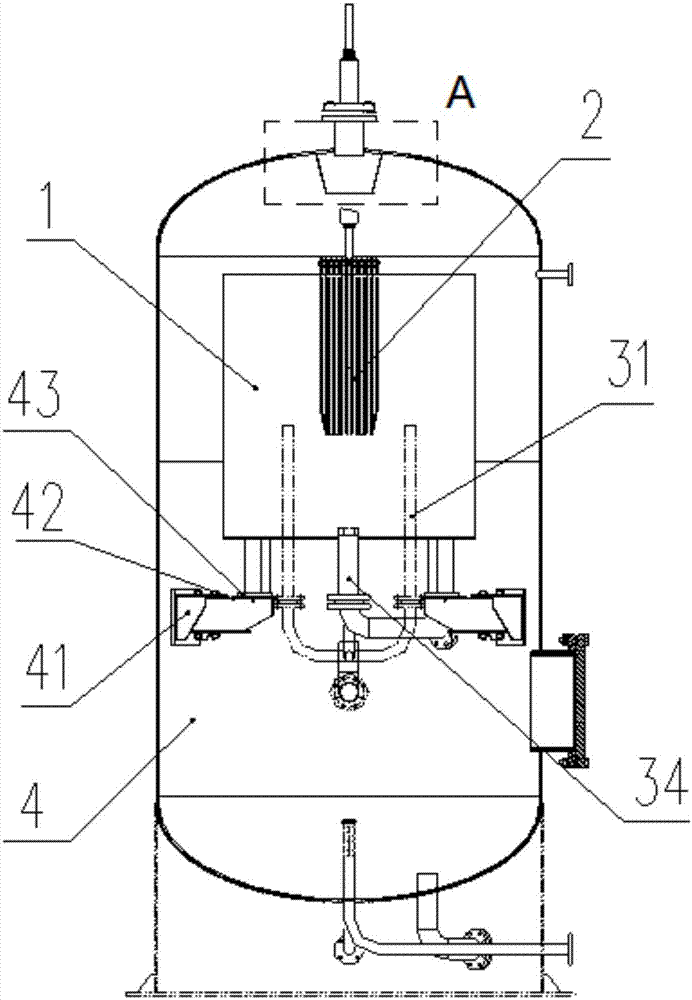

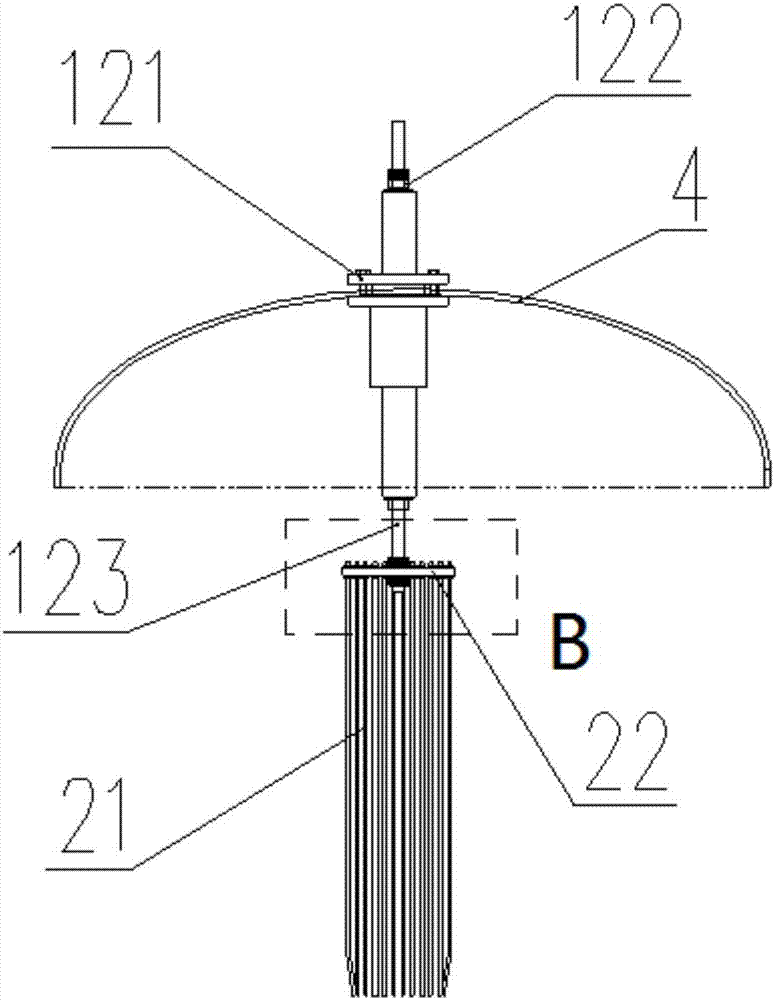

[0038] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

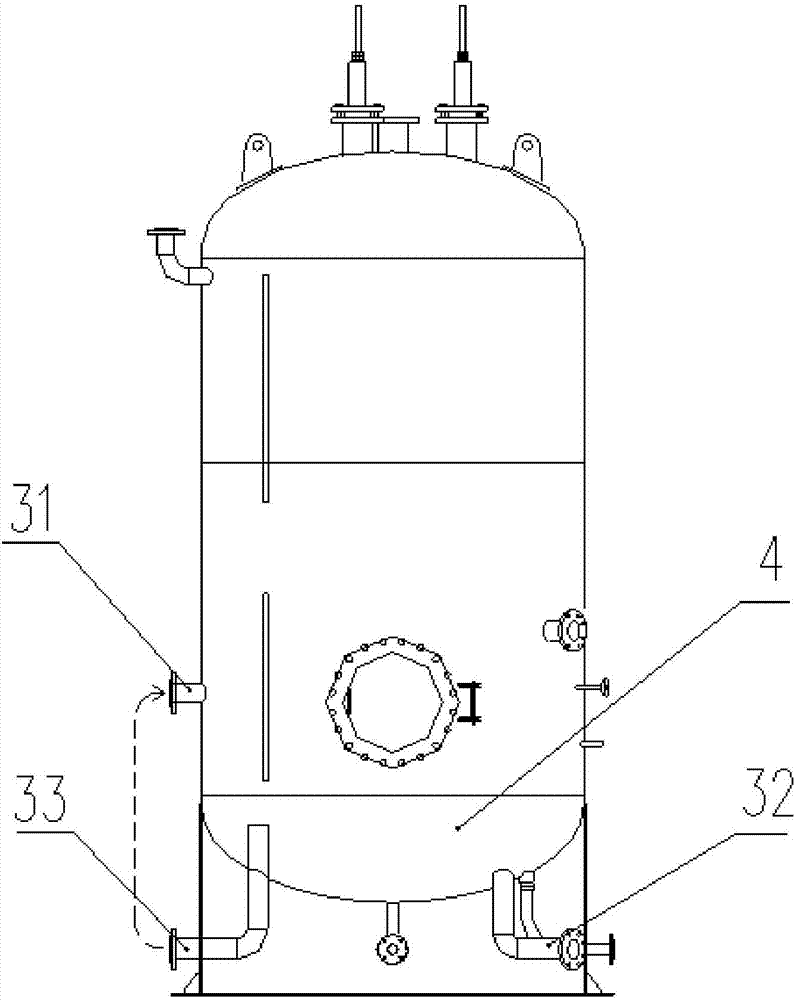

[0039] Please refer to Figure 1-4 , the present invention provides a submerged electrode steam boiler, comprising: an inner cylinder 1 and an electrode device 2, the inner cylinder 1 is used to load an electrolyte solution, and the electrode device 2 is in contact with the electrolyte solution in the inner cylinder 1; the inner cylinder 1 is connected to the neutral line, and the electrode device 2 is connected to the phase line; the electrode device 2 includes an electrode disc 21 and an electrode rod 22, and the electrode disc 21 is provided with no less than two electrode rods 22.

[0040] The electrode device 2 is in contact with the electrolyte solution in the inner cylinder 1. Since the electrode device 2 and the inner cylinder 1 are respectively connected to the phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com