A Piston Ring Radial Rigidity Testing Device

A technology of radial stiffness and testing device, applied in the field of power devices, can solve the problems of influence and inability to test with non-isobaric rings, and achieve the effects of high efficiency, high practicability and simple testing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The device will be described in detail below with reference to the accompanying drawings.

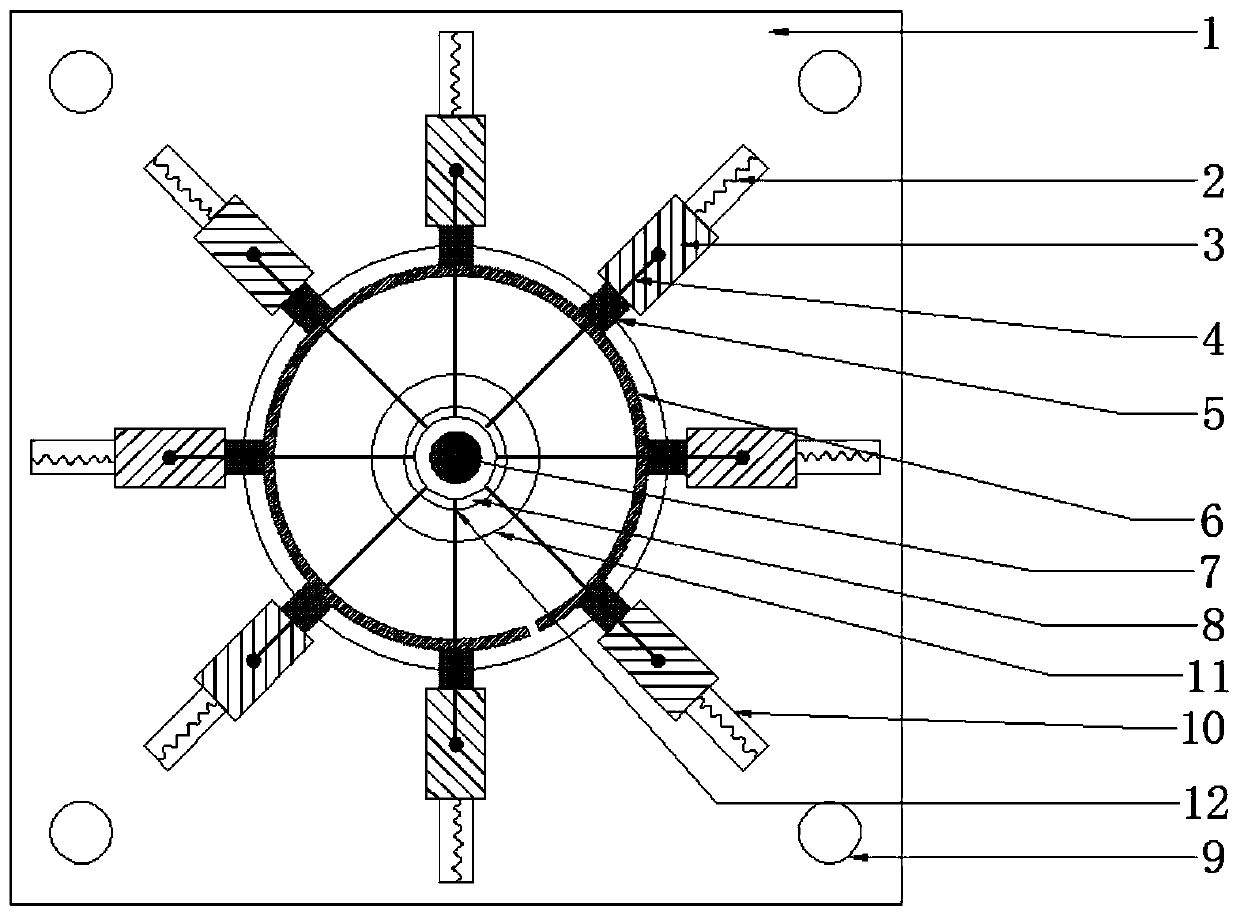

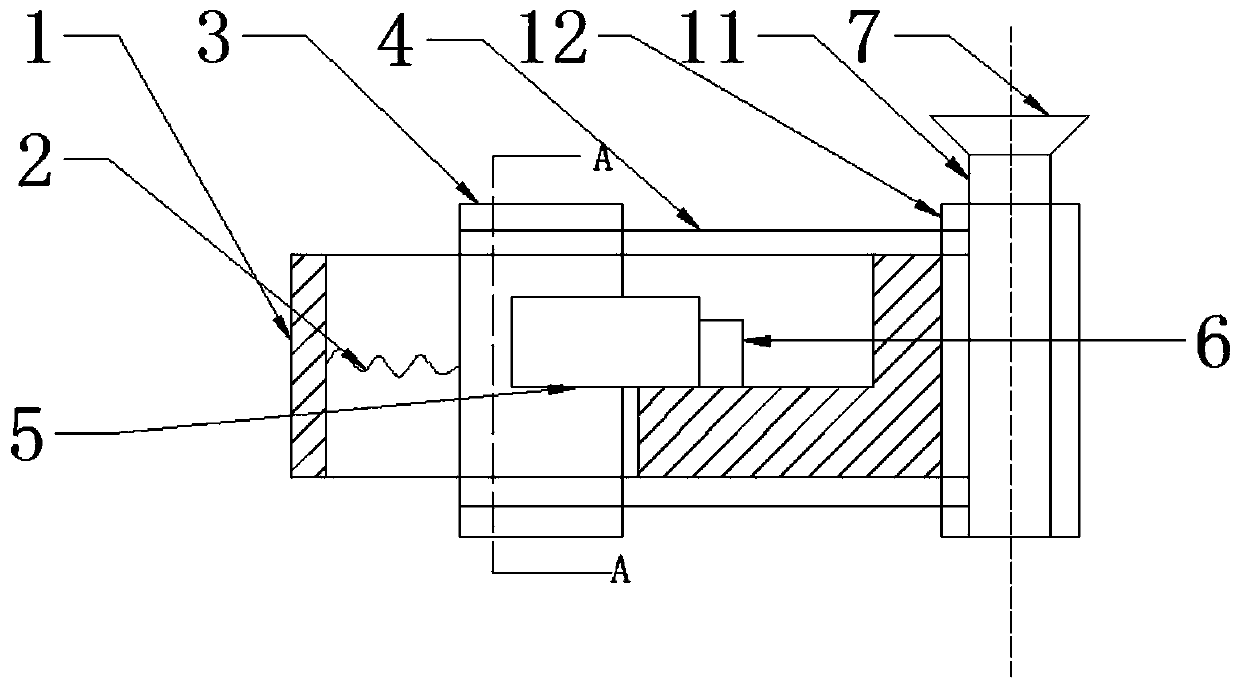

[0020] like figure 1 As shown, a piston ring 6 radial stiffness test device includes: a fixed platform 1, a rotating table and a test assembly; the test assembly includes a tension spring 2, a top column 3, a pressure sensor 5 and a rigid rope 4, such as figure 2 shown; the rotary table includes a knob 7 and a stud 8;

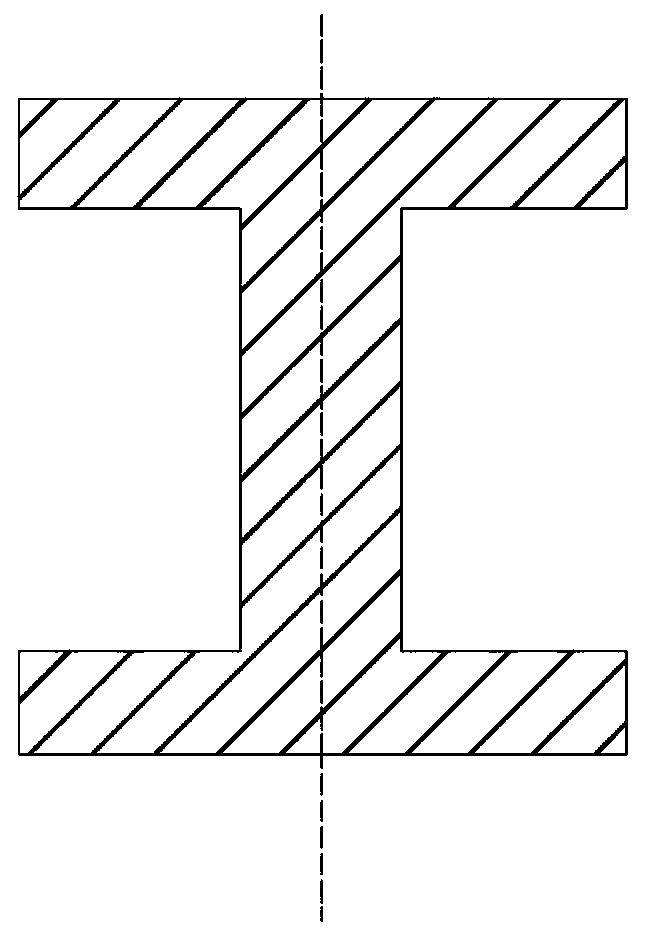

[0021] The fixed platform 1 is fixed on the horizontal foundation base; the middle of the fixed platform 1 has an annular pit; the center of the pit is a circular hollow and a rotary table is installed. The column 8 is installed in the inner threaded pipe 12, and there is a knob 7 on the stud 8; there is a chute 10 along the circumferential direction of the pit, and the test component is installed in the chute 10; the side wall of the chute 10 and the top column 3 side are pulled The spring 2 is connected, and the other side of the top column 3 has a groove mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com