Three-dimensional rotation mechanism for force sense feedback and rotation attitude measurement

A technology of three-dimensional rotation and attitude, which is applied in the direction of control components, mechanical control devices, instruments, etc., and can solve problems such as inapplicable application scenarios, inapplicable usage scenarios, and inability to accurately measure rotation angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

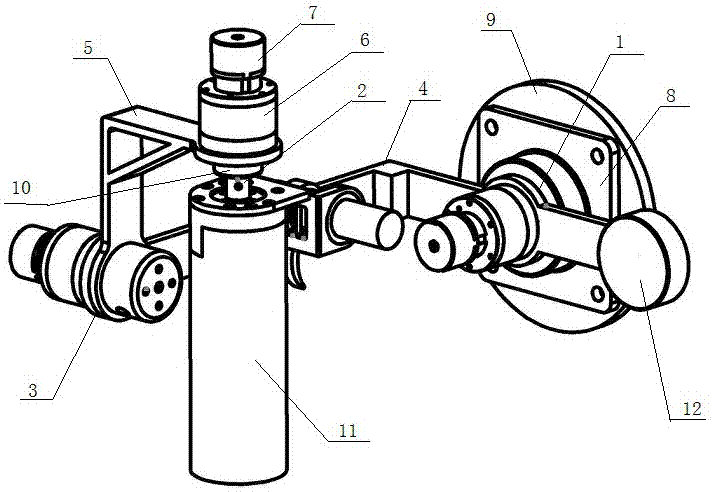

[0019] The three-dimensional rotating mechanism for force feedback and rotational attitude measurement in this embodiment includes rotating shaft A 1, rotating shaft C 2 and rotating shaft B 3 respectively located on the three-dimensional axes of X, Y, and Z, the rotating shaft A and the rotating shaft B They are connected by connecting part two 4, and the rotating shaft B and the rotating shaft C are connected by connecting part one 5, and the rotating shaft A, rotating shaft B, and rotating shaft C are respectively installed with a magneto-rheological damper in the axial direction 6, each magneto-rheological damper is equipped with an inertial measurement unit 7. Magneto-rheological damper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com