High-speed railway transportation system

A transportation system, high-speed railway technology, applied to railway car body parts, etc., to achieve high efficiency, improve safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Most of the existing high-speed railway lines in operation have a design speed of more than 350 kilometers per hour, but due to considerations such as safety, the actual operating speed is only maintained within 300 kilometers per hour. Therefore, how to improve the safety of high-speed railway operation in order to increase the speed of high-speed railway operation is an urgent problem to be solved.

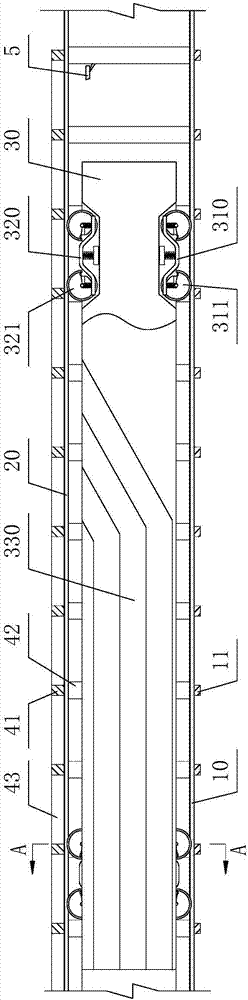

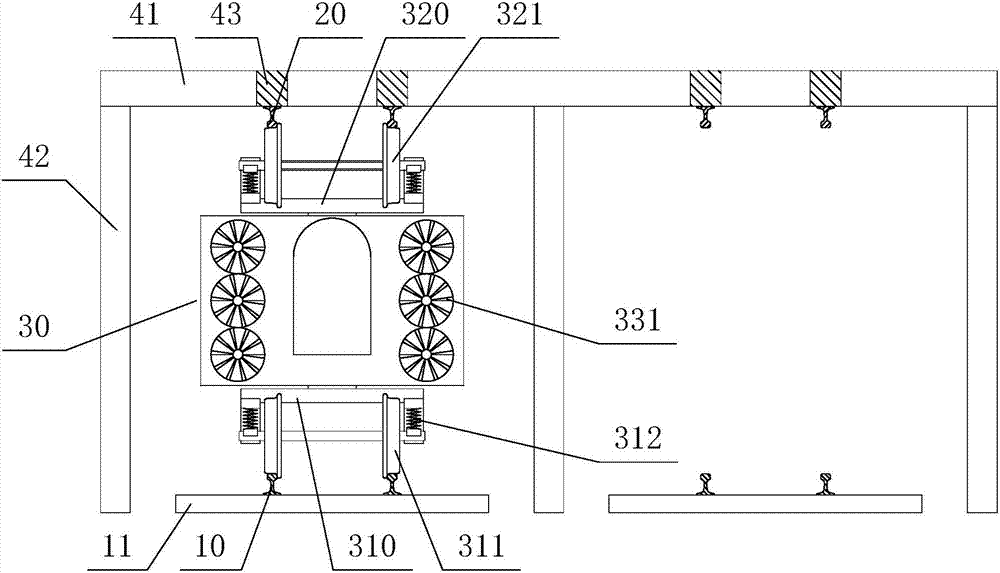

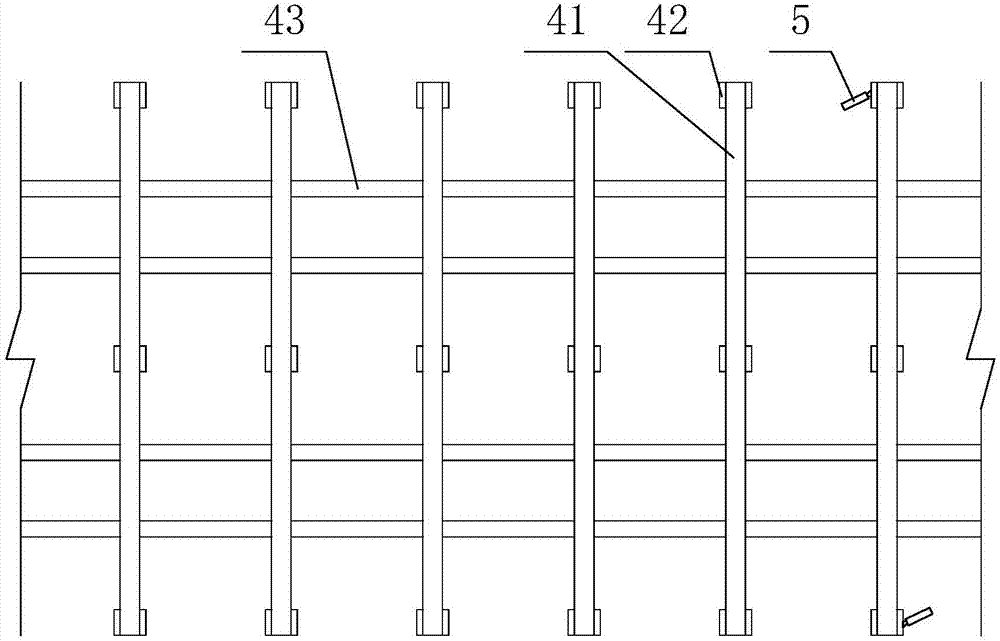

[0028] Aiming at the technical problems existing in the above-mentioned prior art, an embodiment of the present invention provides a high-speed railway transportation system, including a track system and a train, the track system includes tracks laid on the ground, and the train includes carriages and The suspension at the bottom of the compartment, the suspension is provided with a wheel pair that matches the working surface of the track, the suspension is provided with a power device that drives the wheel pair to rotate, and the track is the first track, the suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com