Lightweight automobile engine cover

A hood and lightweight technology, applied to vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems of insufficient energy saving and emission reduction, excess component strength, heavy vehicle weight, etc., and achieve light weight, Easy molding, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

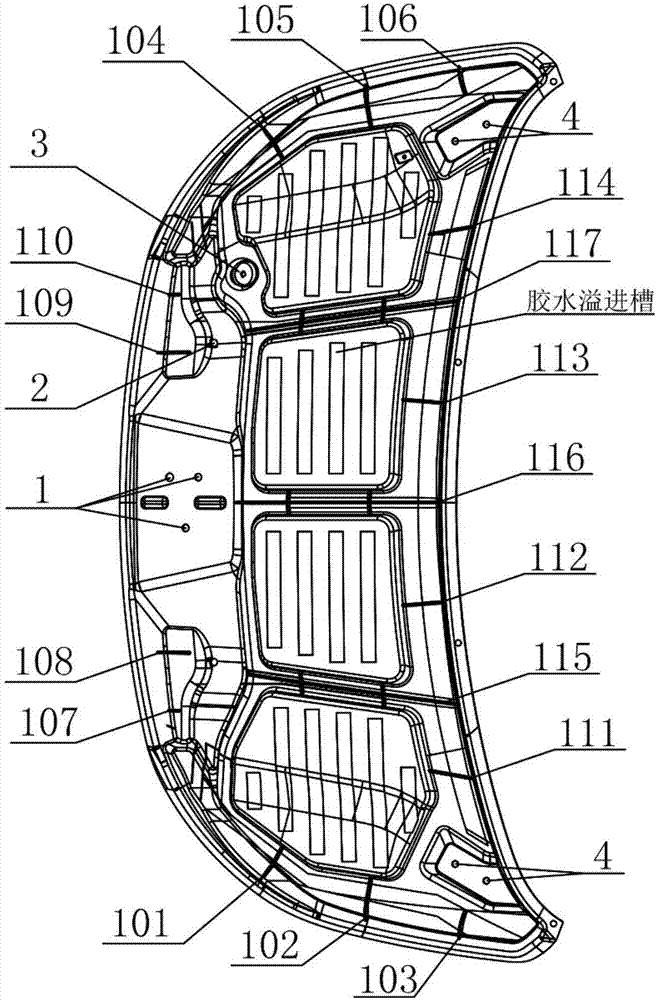

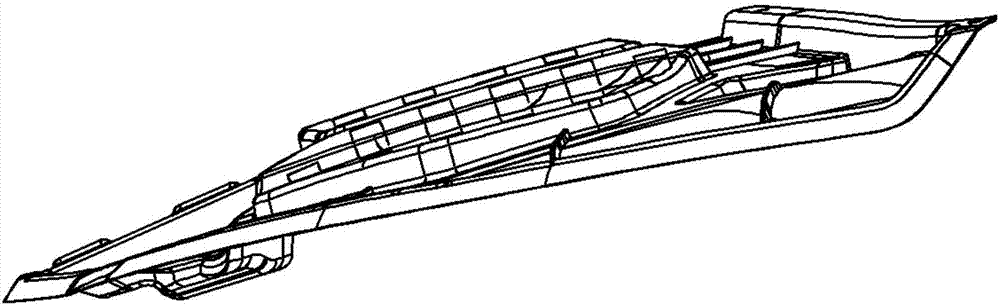

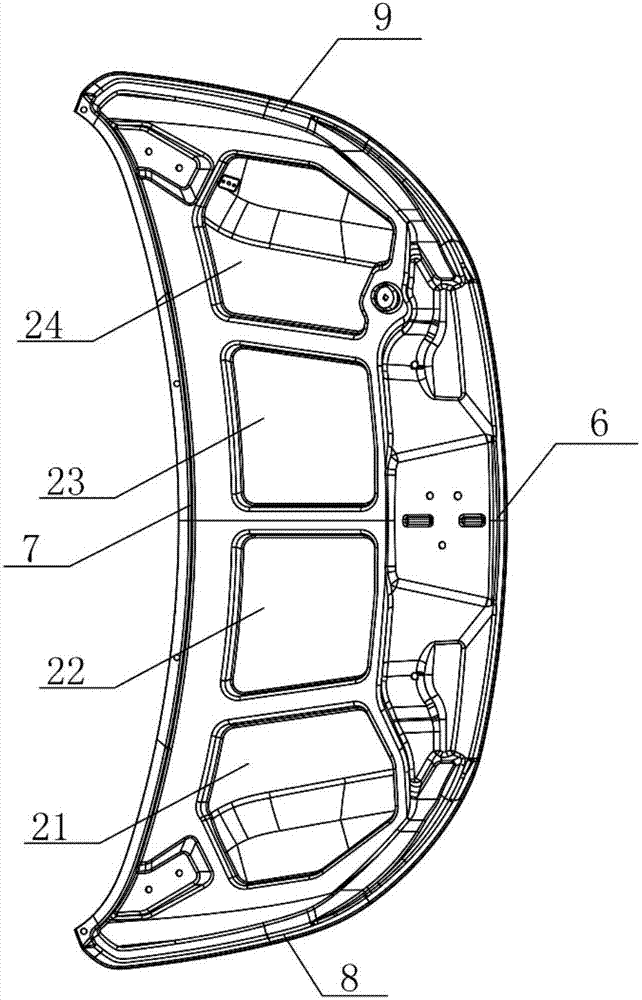

[0043] combine as figure 1 , Figure 4 , Figure 5 and Figure 6 Shown, a kind of lightweight automobile engine cover, described engine cover comprises outer plate and inner plate, and described inner plate is provided with lock installation hole (1), drain hole (2), strut installation hole (3) and hinge The hole (4) is characterized in that:

[0044]The outer panel and the inner panel are integrally formed respectively, and the outer panel and the inner panel are assembled with an adhesive; the surface of the inner panel and the outer panel is also provided with a number of reinforcing ribs and a plurality of protrusions platform area; the plurality of ribs are used to increase the overall deformation resistance of the inner panel; the plurality of boss areas are respectively provided with a number of glue overflow grooves to prevent the glue from overflowing to other areas during the gluing assembly process of the outer panel and the inner panel .

[0045] combine fig...

Embodiment 2

[0060] combine as figure 1 , Figure 4 , Figure 5 and Figure 6 Shown, a kind of lightweight automobile engine cover, described engine cover comprises outer plate and inner plate, and described inner plate is provided with lock installation hole (1), drain hole (2), strut installation hole (3), hinge The hole (4) is characterized in that:

[0061] The outer panel and the inner panel are respectively integrally formed, and the outer panel and the inner panel are assembled with an adhesive; the surface of the side where the inner panel and the outer panel are bonded is also provided with a number of reinforcing ribs and a plurality of bosses area; the plurality of reinforcing ribs are used to increase the overall deformation resistance of the inner panel; the plurality of boss areas are respectively provided with a number of glue overflow grooves to prevent the glue from overflowing to other areas during the gluing assembly process of the outer panel and the inner panel.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com