Parallel type vector propulsion device with two degrees of freedom

A vector propulsion, parallel technology, applied in ship propulsion, propulsion components, transportation and packaging, etc., can solve the problems of large range of motion, cumbersome control, redundant degrees of freedom, etc., to reduce power loss, high system stability, The effect of turning at a large angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

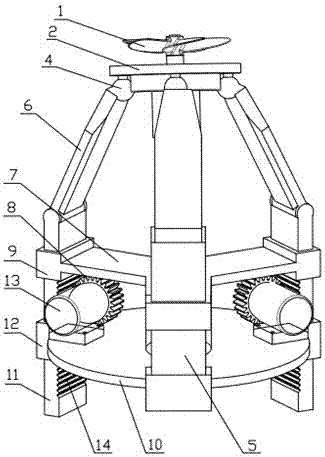

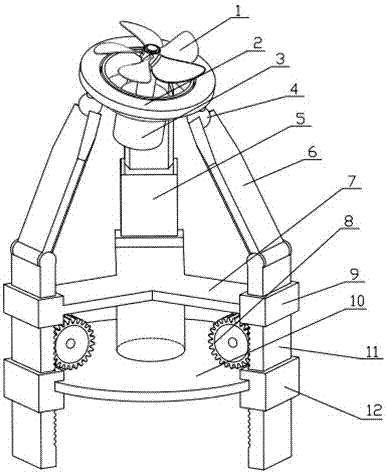

[0016] Such as figure 1 , figure 2 The shown two-degree-of-freedom parallel vector propulsion device is provided with a mounting base 10 and a driving base 2. The circular array on the mounting base 10 is provided with three longitudinally arranged and parallel support arms, and two of the three support arms are The guide device can be vertically moved on the installation base 10. The guide device is: the installation base 10 is provided with two guide slides 12, and the guide slides 12 are provided with guide slide holes. The longitudinally movable support The arm 11 is longitudinally slidably arranged in the guide sliding hole. Another support arm 5 is fixedly installed on the mounting base 10, and the mounting base 10 is provided with a support arm drive device for driving the support arm to move longitudinally, and the support arm drive device is connected with the support arm. figure 1 , figure 2 It can be seen from the figure that the supporting arm driving device i...

Embodiment 2

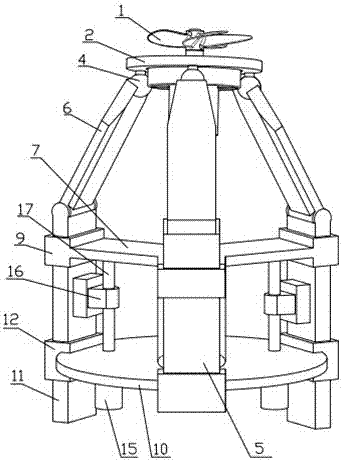

[0020] Such as image 3 , Figure 4 The shown two-degree-of-freedom parallel vector propulsion device is provided with a mounting base 10 and a driving base 2. The circular array on the mounting base 10 is provided with three longitudinally arranged and parallel support arms, and two of the three support arms are The guide device can be vertically moved on the installation base 10. The guide device is: the installation base 10 is provided with two guide slides 12, and the guide slides 12 are provided with guide slide holes. The longitudinally movable support The arm 11 is longitudinally slidably arranged in the guide sliding hole. Another support arm 5 is fixedly installed on the mounting seat 10, and the mounting seat is provided with a support arm drive device for driving the support arm to move longitudinally, and the support arm drive device is connected with the support arm. figure 1 , figure 2 It can be seen from the figure that the drive device of the support arm is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com