Efficient and adjustable vacuum control method and system used for power plant

A vacuum control and high-efficiency technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of difficult control of manual valves, impact on unit operation safety, difficulty in maintaining design conditions, etc., to improve work efficiency, Avoiding safety risks in unit operation, good performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

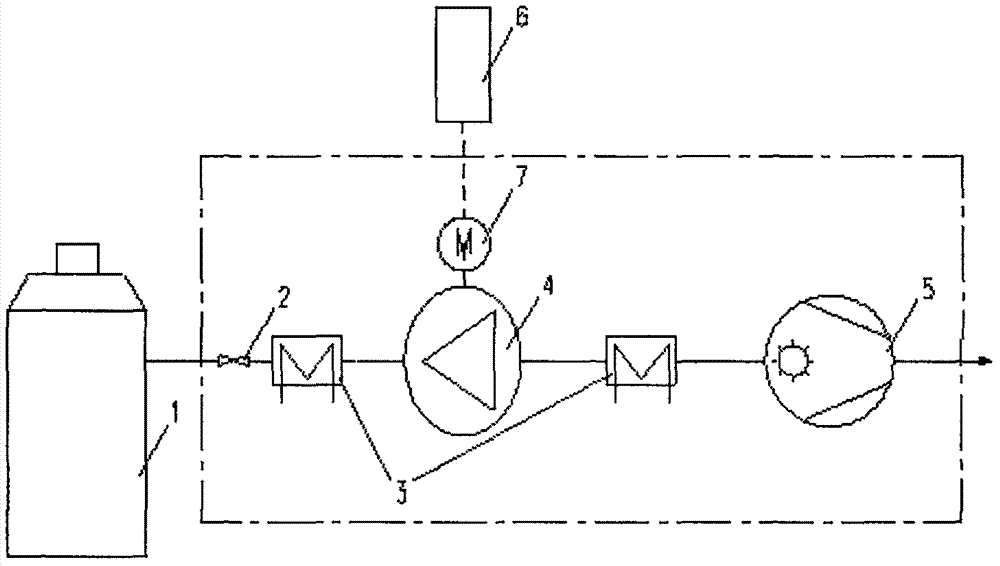

[0063] Such as figure 1 As shown, the high-efficiency adjustable vacuum control method used in power plants in this embodiment includes:

[0064] The steam extraction ports on the condenser are respectively connected with a main steam extraction device, and the main steam extraction device includes a positive displacement vacuum pump communicated with the steam extraction port on the condenser through a main steam extraction pipeline. The vacuum pump is connected in series with a final-stage water circulation vacuum pump; the positive displacement vacuum pump is electrically connected to a variable frequency motor, the positive displacement vacuum pump is driven by a variable frequency motor, and the variable frequency motor is connected to a controller; the vacuum control method of the condenser includes:

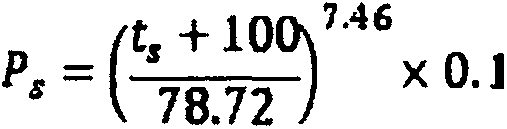

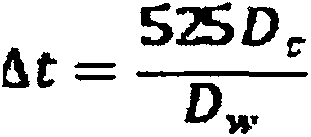

[0065] Collect parameters that affect the vacuum of the condenser, the parameters include: condenser cooling water inlet temperature t w1 , steam turbine condensing steam...

Embodiment 2

[0086] This embodiment is used in a high-efficiency adjustable vacuum control system of a power plant, including: a condenser 1, and the steam extraction ports on the condenser are respectively connected with a main extraction device and a standby steam extraction device, wherein the main extraction The steam device includes a volumetric vacuum pump 4 communicated with the steam extraction port on the condenser through the main steam extraction pipeline, and the volumetric vacuum pump is connected in series with a final water circulation vacuum pump 5; between the volumetric vacuum pump and the condenser The main steam pipeline between them is provided with a first switching valve 2; the positive displacement vacuum pump is electrically connected to a variable frequency motor, and the positive displacement vacuum pump is driven by a variable frequency motor 7; a measuring unit 8 is connected to the condenser, The measuring unit includes: a temperature sensor for measuring the i...

Embodiment 3

[0106] This embodiment is used in the high-efficiency adjustable vacuum control system of the power plant. On the basis of Embodiment 2, it also includes a backup steam extraction device (not shown in the figure), and the backup steam extraction device includes a vacuum connected to the condenser. The standby steam extraction pipeline is connected in series with a primary water circulation vacuum pump and a secondary water circulation vacuum pump; the standby steam pipeline between the primary water circulation vacuum pump and the condenser is provided with a second on-off valve. The first on-off valve and the second on-off valve described above are electric valves, pneumatic valves or manual valves.

[0107] The spare steam pipeline between the primary water circulation vacuum pump and the condenser is provided with a second on-off valve, and the first on-off valve and the second on-off valve are electric valves, pneumatic valves or manual valves.

[0108] The inlets of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap