Plastic de-molding force test mold and test method thereof

A technology for testing mold and demoulding force, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of damage to the surface condition of parts, surface scratches, material adhesion residues, etc., to save the cycle and change of comprehensive inspection The effect of angle fast and convenient, comprehensive and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

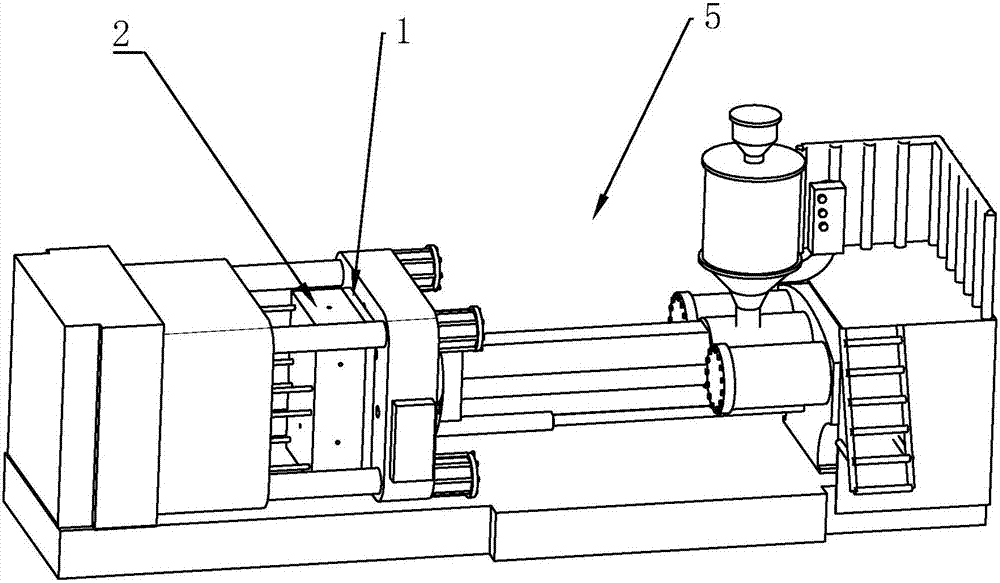

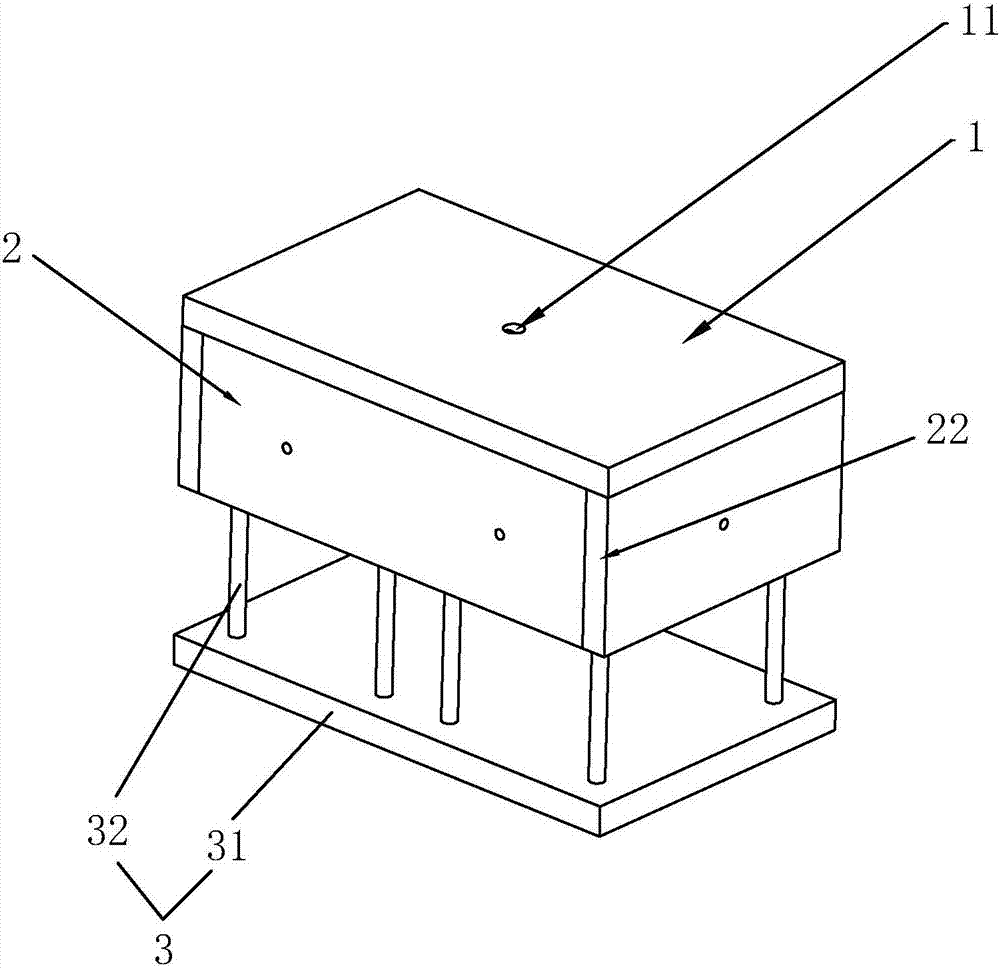

[0030] Please refer to the attached figure 1 , a schematic diagram of a plastic demoulding force test mold, which includes an injection molding machine 5, a fixed mold 2, a movable mold 1 and an ejector device 3 in turn, wherein the fixed mold 2 is shaped like a cuboid and includes two cuboid cavities 21; The movable mold 1 is provided with a main channel hole, and the main channel hole flows into the two cavities 21 respectively through two branch channels. In the cavity 21 formed between the molds 1. The raw material can be at least one of polyethylene, polypropylene, polycarbonate, ABS, PS, and PA. Of course, in order to test the performance of different demoulding forces after adding different raw materials, it can also be a variety of combinations.

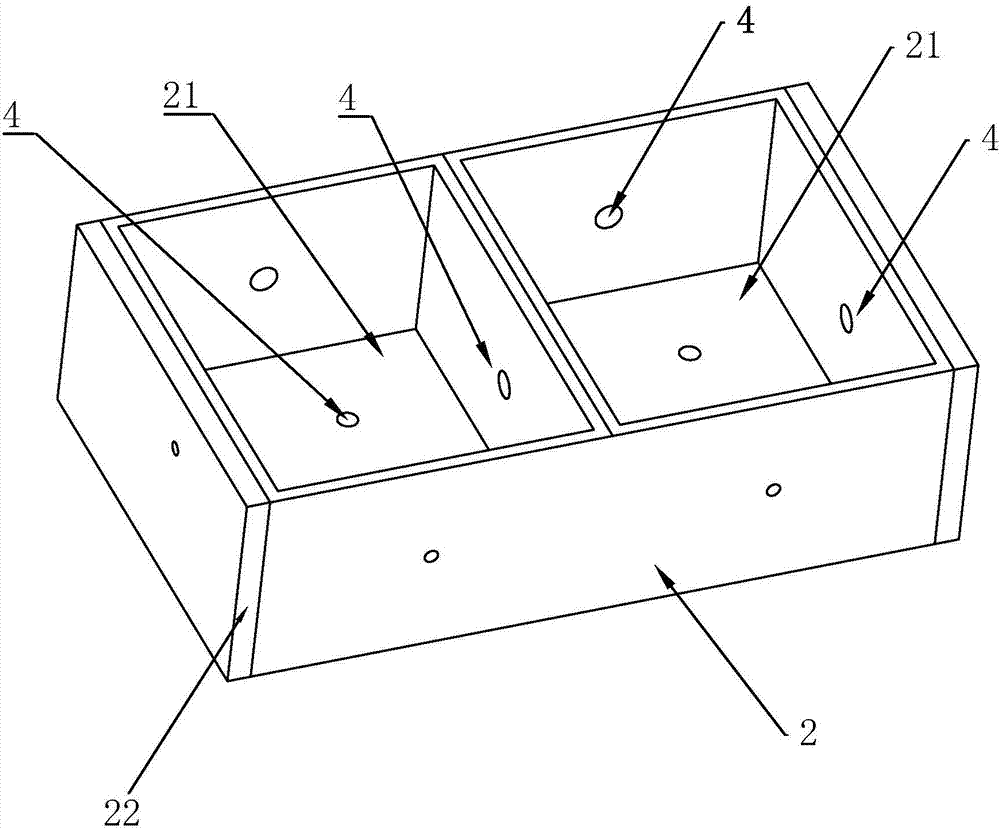

[0031] Please refer to the attached figure 2 , 3 A pressure sensor 4 is arranged at the center of the four side walls and the bottom of the cavity 21 of the fixed mold 2, and the top of the pressure sensor 4 is on the sam...

Embodiment 2

[0038] Please refer to the attached Figure 4 , on the basis of Example 1, the difference from Example 1 is that there is a cube-shaped cavity 21 in the fixed mold 2, which can collect four sets of data for comparison after injection molding again. For analysis, the more groups collected, the smaller the error rate. The ejector device 3 includes ejector pins 32 and ejector plates 31, and each cavity 21 has four ejector pins 32, and the top of the ejector pins 32 is also set There is a pressure sensor 4, so that the data of the initial demoulding force on the thimble 32 can be obtained, and errors can be further reduced.

Embodiment 3

[0040] On the basis of embodiment 1, in the process of processing unit, before calculating the average value, the collected Ft1a, Ft1b, Ft1c, Ft1d, Ft1e... Ft1n and Ft2a, Ft2b, Ft2c, Ft2d, Ft2e.. .. Ft2n removes the maximum value and the minimum value from the two sets of data, thereby reducing the error value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com