Chopping board device

A cutting board and board surface technology, applied in the field of kitchen utensils, can solve the problems of cutting board pollution and user inconvenience, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a chopping board, and the chopping board is provided with a drain rack, so as to facilitate draining.

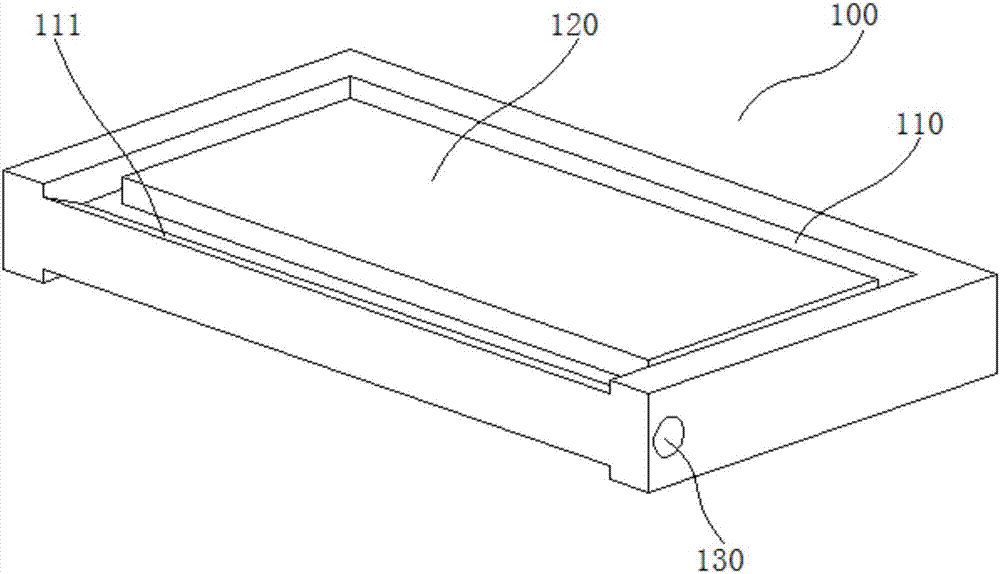

[0041]A chopping board in this embodiment includes a plate-shaped chopping board main body 100 , and a draining rack is provided on the chopping board main body 100 .

[0042] Such as figure 1 Shown is a schematic diagram of the cutting board main body 100 .

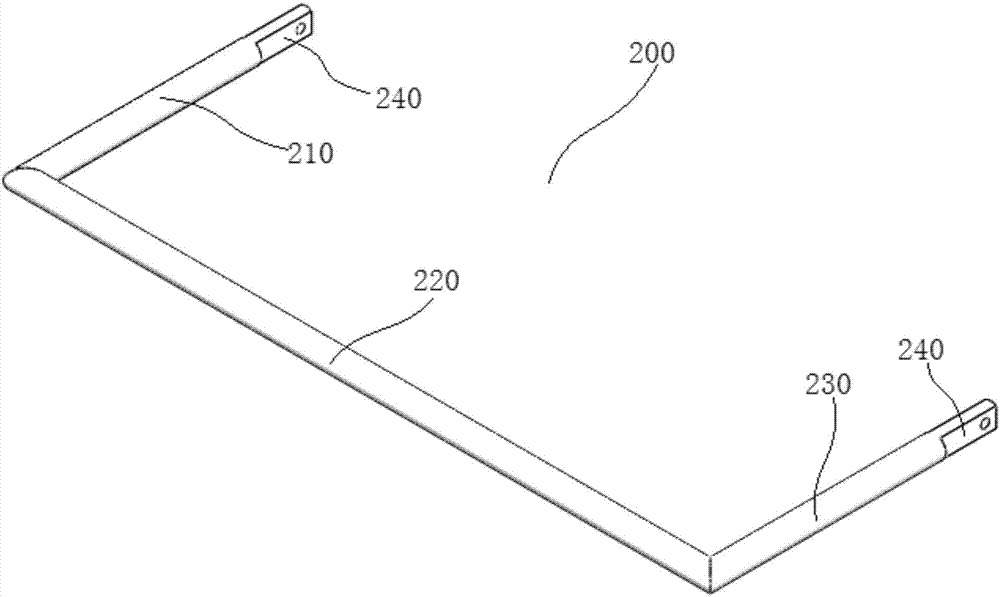

[0043] Such as figure 2 As shown, the drain rack includes a "U" shaped drain rack body 200 as a whole, and the drain rack body 200 includes a first strut 210 , a second strut 220 and a third strut 230 integrally connected in sequence.

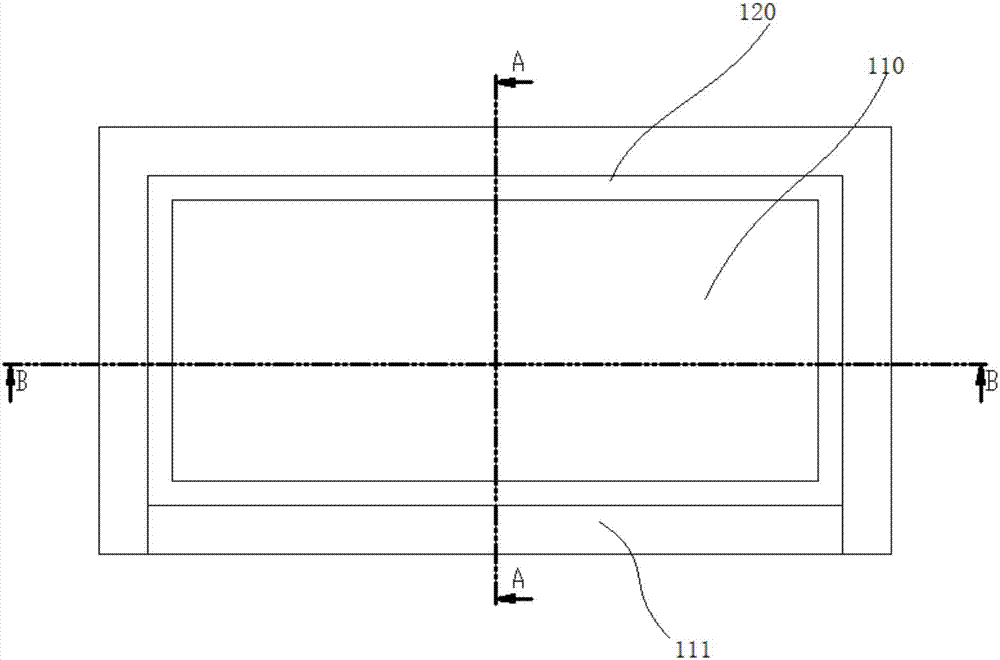

[0044] combine Figure 3-5 As shown, the two board surfaces of the chopping board main body 100 are provided with an annular sump 110, the middle part of the sump 110 is a vegetable cutting area 120, and the sump 110 is located at the other side opposite to the one side of the chopping board main body 100. The sidewall is inwardly recessed to form a ...

Embodiment 2

[0056] This embodiment provides a cutting board device, which is preferably convenient for users to use.

[0057] Such as Figure 10 , 13 As shown in and 14, an anvil device of the present embodiment includes an anvil bracket 1000, an anvil body 100 is provided at an anvil bracket 1000; an anvil bracket 1000 includes an anvil bracket main body 1010, an The anvil board placement groove 1011 of the main body 100; one side of the anvil board main body 100 is provided with a rotating shaft hole 130 along the length direction, and a rotating shaft 1012 is arranged in the rotating shaft hole 130, and both ends of the rotating shaft 1012 protrude from the rotating shaft hole 130; the anvil board placement groove 1011 corresponds to The side walls at both ends of the rotating shaft 1012 are provided with sliding grooves 1013, and the two ends and the middle of the lower side walls of the sliding groove 1013 are respectively provided with a first positioning groove 1013a, a second pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com