Stage hydraulic driving and damping fireproof isolation equipment

A fire isolation, hydraulic technology, applied in fire rescue, medical science, dental prosthetics, etc., can solve problems such as difficulty in adapting to performing arts and production, complex hydraulic system, hydraulic motor damping, etc., to achieve safe and reliable use and simple transmission system. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

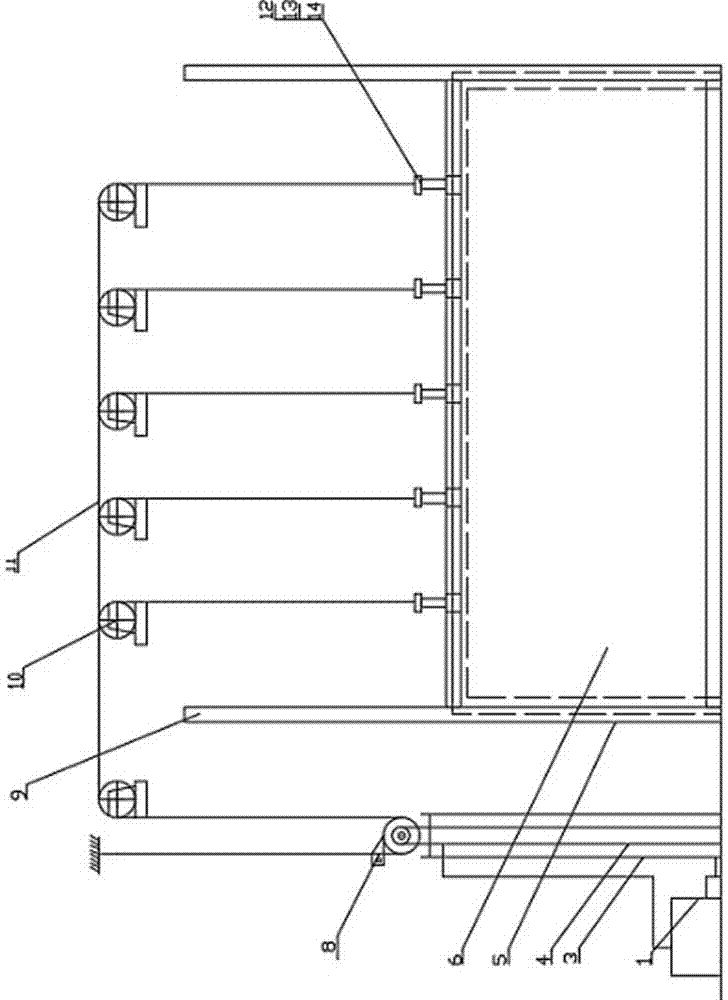

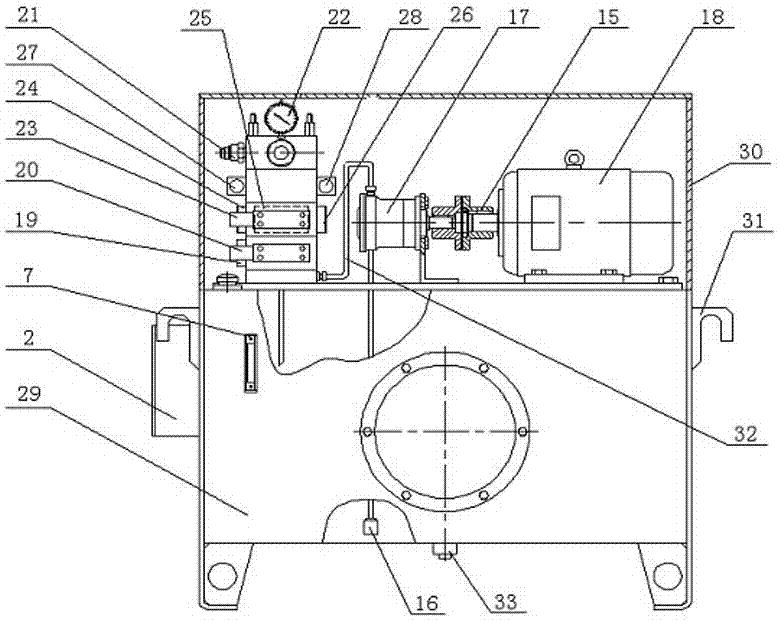

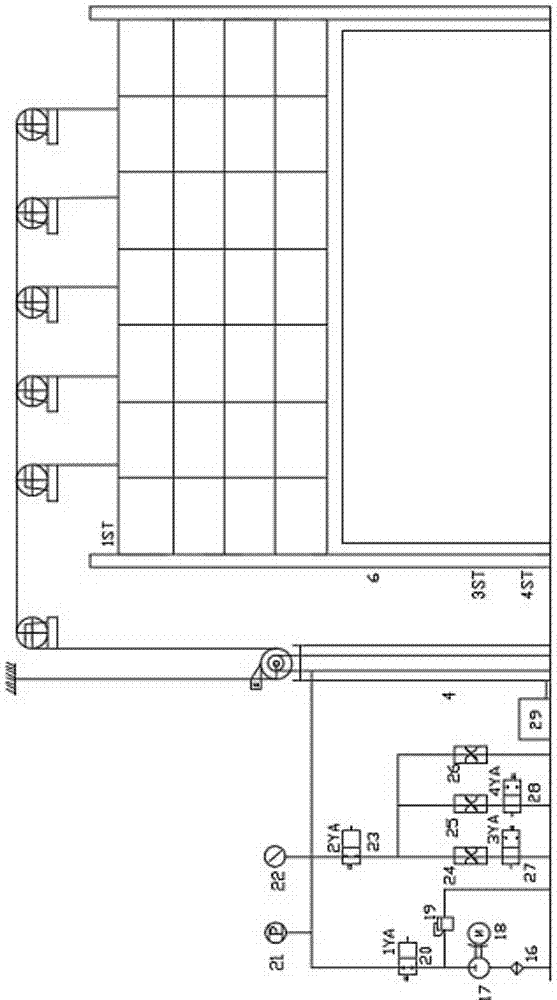

[0007] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in , the present invention is a stage hydraulically driven, damped and fire-proof isolation equipment, including a hydraulic control system 1, a damping cylinder 4, the damping cylinder ≤ 5m, the damping cylinder 4 is connected with the hydraulic control system 1, and the upper end of the rectangular isolation body 6 Several steel wire ropes 11 are evenly connected, and the steel wire ropes 11 are fixedly connected to the wall through the corresponding pulley blocks 10 and the upper end of the vertical rod bypassing the damping cylinder 4. One side of the isolation body 6 is provided with a guide rail travel switch 5 and a limit position sensor. 9 replenish the oil cylinder; the limit position sensor 9 can alarm and replenish the oil and start the limit device 8 on the oil cylinder at the same time. Connected; the hydraulic oil tank 29 of the hydraulic control system 1 is provided with a distribution box 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com