Automatic weight-hanging multi-carrier-roller suspension type electronic belt scale

An electronic belt scale and suspension type technology is applied in the field of cargo weighing, which can solve the problems of difficulty in realizing automatic code registration, excessive scale structure, and high installation requirements, and achieves small dimensions, good versatility, and transmission links. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

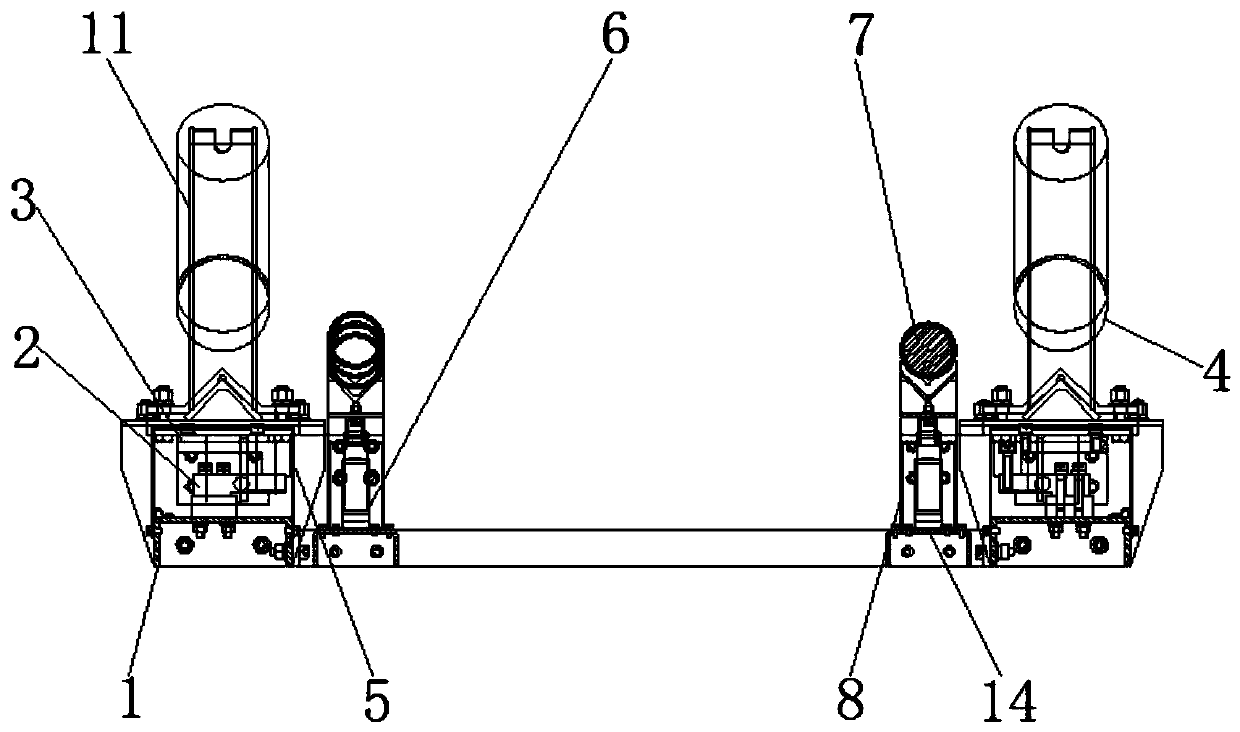

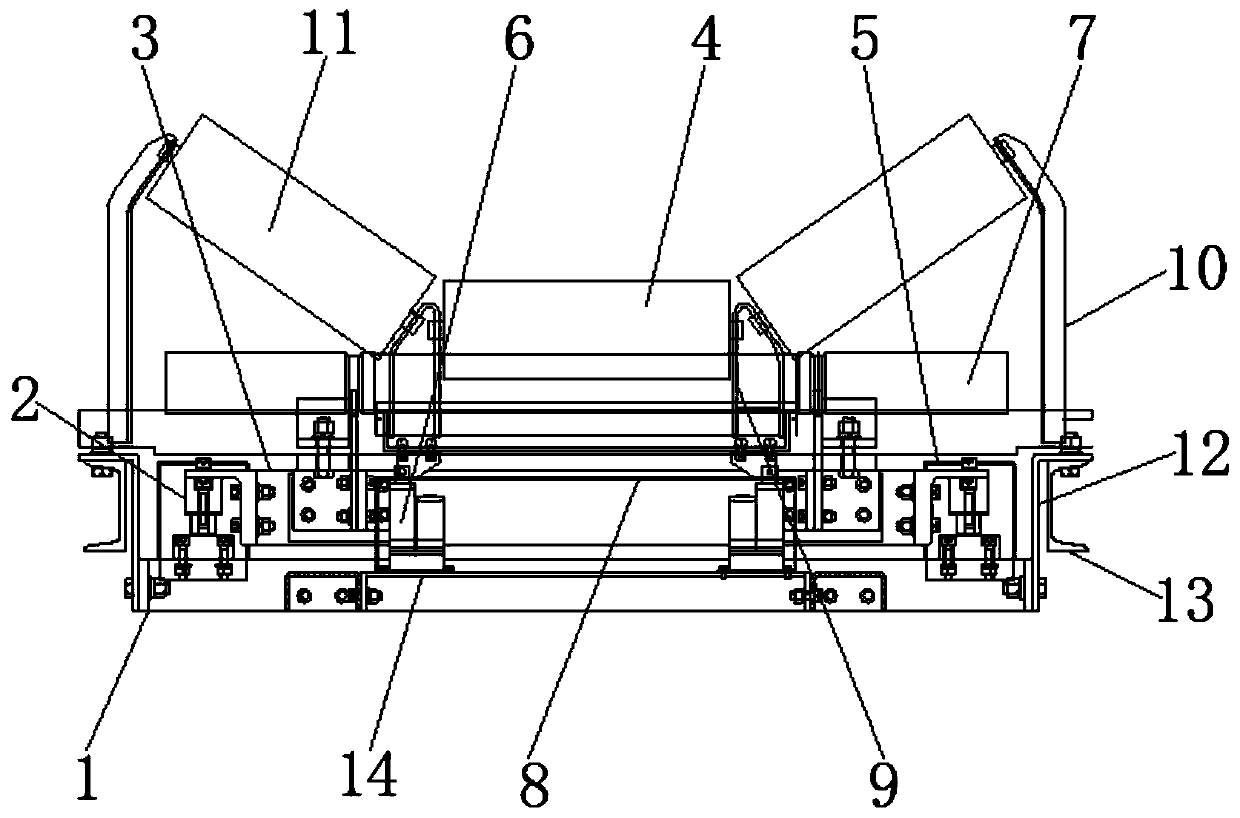

[0028] Reference Figure 1-2 , Automatic hanging code multi-roller suspension electronic belt scale, including the scale body mounting frame 1, the top of the scale body mounting frame 1 is fixedly connected with two load cells 2 on both sides, and the top of the load cell 2 is fixedly connected with a supporting roller Mounting platform 3, the top of the roller mounting platform 3 is fixedly connected with a supporting mechanism, the supporting mechanism includes two supporting plates 10, the sides of the two supporting plates 10 close to each other are slidably provided with second supporting rollers 11, two The side of the second support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com