Holding pole traction type integrated pumping unit

A pumping unit and traction technology, which is applied in the field of rod-holding traction integrated pumping units, can solve the problems of complex structure and easy damage of sucker rods, and achieve the effect of small size, compact structure and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

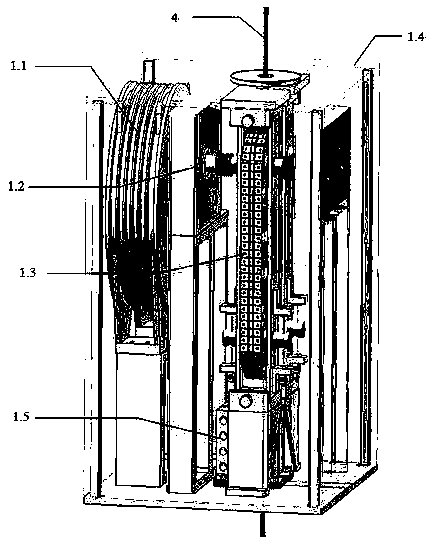

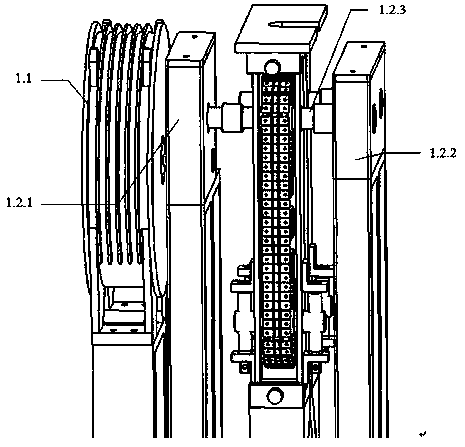

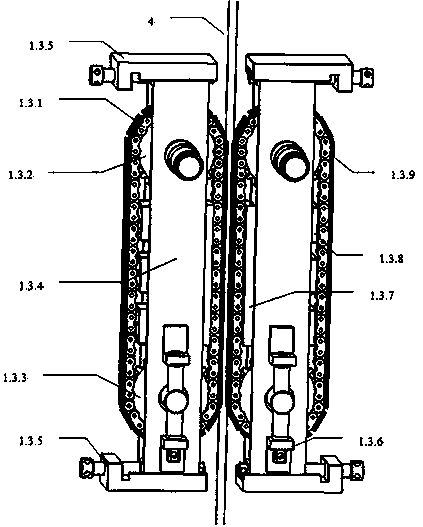

[0035] see Figure 1~7 , the present invention relates to a rod-drawing integrated pumping unit, said rod-holding integrated pumping unit includes a pumping unit host 1, a sucker rod conduit mechanism 2, a wellhead docking mechanism 3, a sucker rod 4 and a drive control system 5; the sucker rod conduit mechanism 2 is installed on the top surface of the pumping unit main unit 1; the lower bottom surface of the pumping unit main unit 1 is installed on the wellhead docking mechanism 3; the sucker rod 4 passing through the wellhead docking mechanism 3 and the main pumping unit 1, the top of the sucker rod 4 is set inside the sucker rod conduit mechanism 2; the drive control system 5 is set next to the main pumping unit 1 , and connected to the main unit 1 of the pumping unit through a cable;

[0036] The main engine 1 of the pumping unit includes a permanent magnet motor 1.1, a transmission mechanism 1.2, a pole holding traction mechanism 1.3, a combined box body 1.4 and a brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com