Polishing equipment for wood package

A wood packaging and equipment technology, applied in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve problems such as the inability to meet the needs of wood packaging polishing, affecting the health of operators, and difficult to guarantee the polishing effect. , to achieve the effect of reducing labor input, simple structure and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

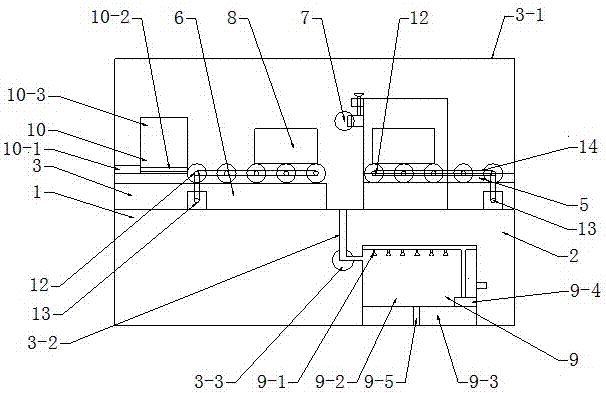

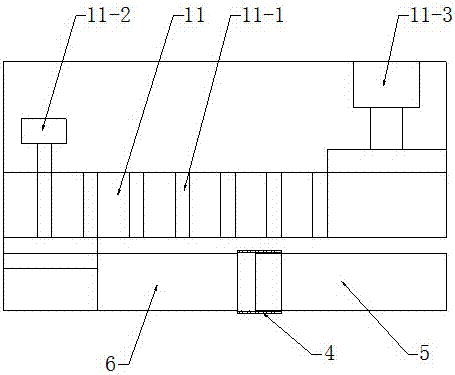

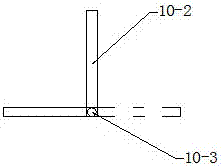

[0018] The present invention relates to a kind of polishing equipment for wooden packaging, such as figure 1 and figure 2 Shown includes a frame 1, a base 2 and a workbench 3, the workbench 3 is provided with a guide device 4 for clamping the wooden package 8, and the left and right sides of the guide device 4 are respectively provided with The first feeding mechanism 5 and the second feeding mechanism 6, a polishing roller 7 is arranged above the guide device 4, a dustproof cover 3-1 is arranged above the workbench 3, and the dustproof cover 3-1 is connected with a dust removal device 9, the second feeding mechanism 6 is connected with an overturning device 10, the overturning device 10 is connected with a third feeding mechanism 11 that transports the overturned wooden package to the first feeding mechanism 5, and the polishing roller 7 is connected with Polishing motor 12, polishing roller 7 are copper wire polishing rollers.

[0019] In the specific implementation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com