A kind of skateboard brick pressing brick mould

A technology for sliding bricks and pressing bricks, which is applied to ceramic extrusion dies and other directions, can solve the problems of insufficient forming effect of artificial cloth, large dependence on pressurization process, inconsistent density, etc., so as to avoid insufficient performance, improve anti-scouring ability, The effect of increasing the degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

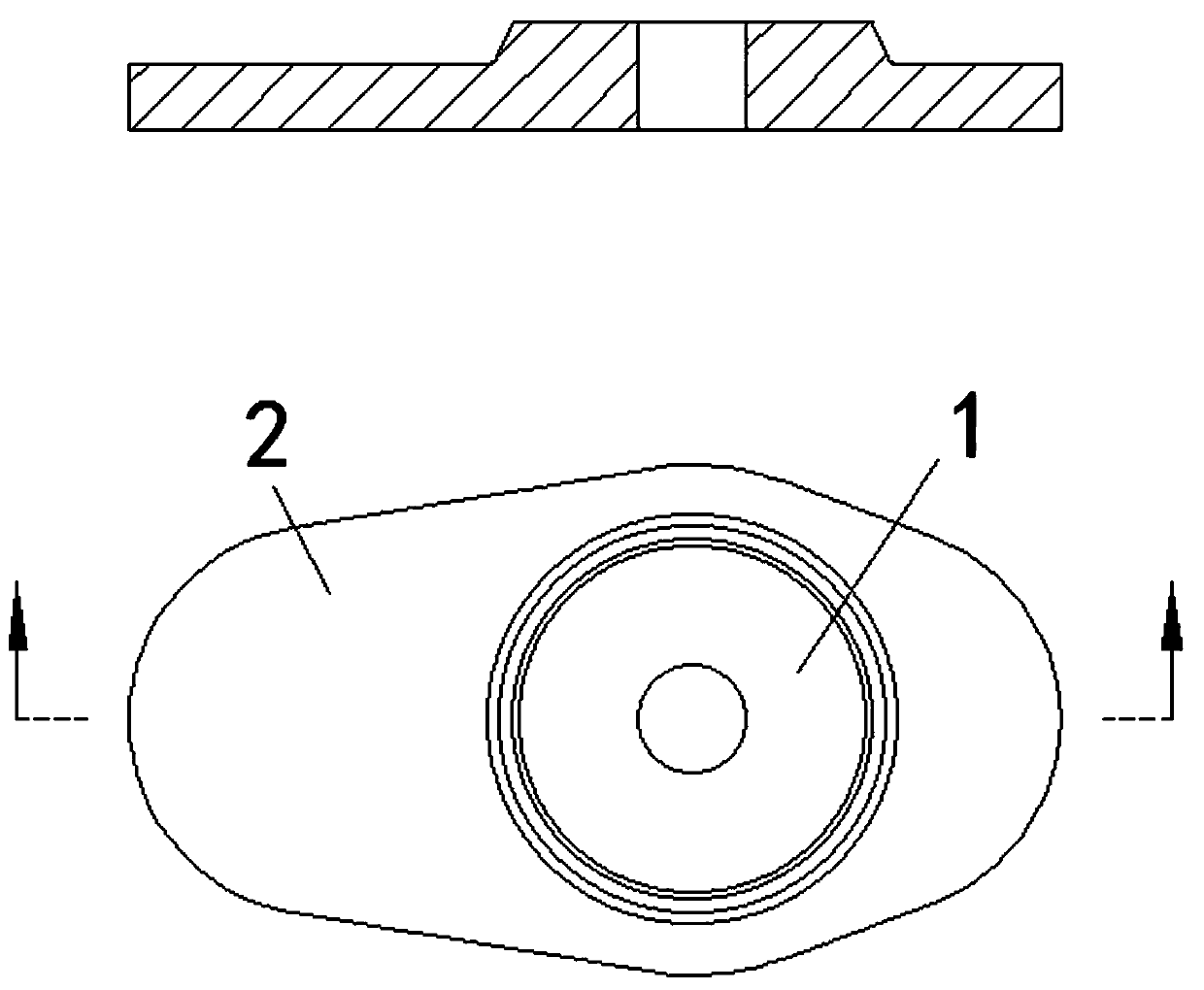

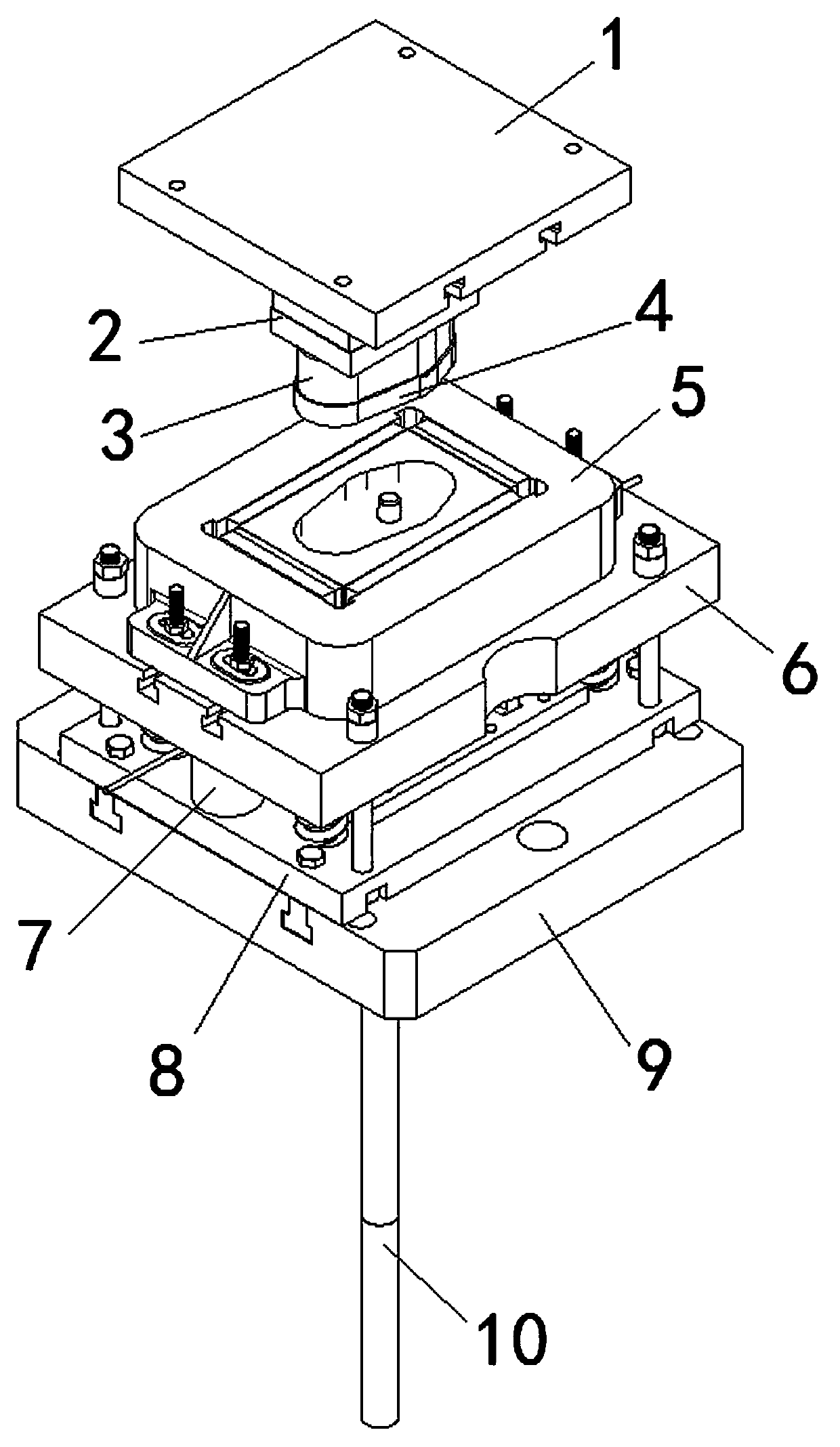

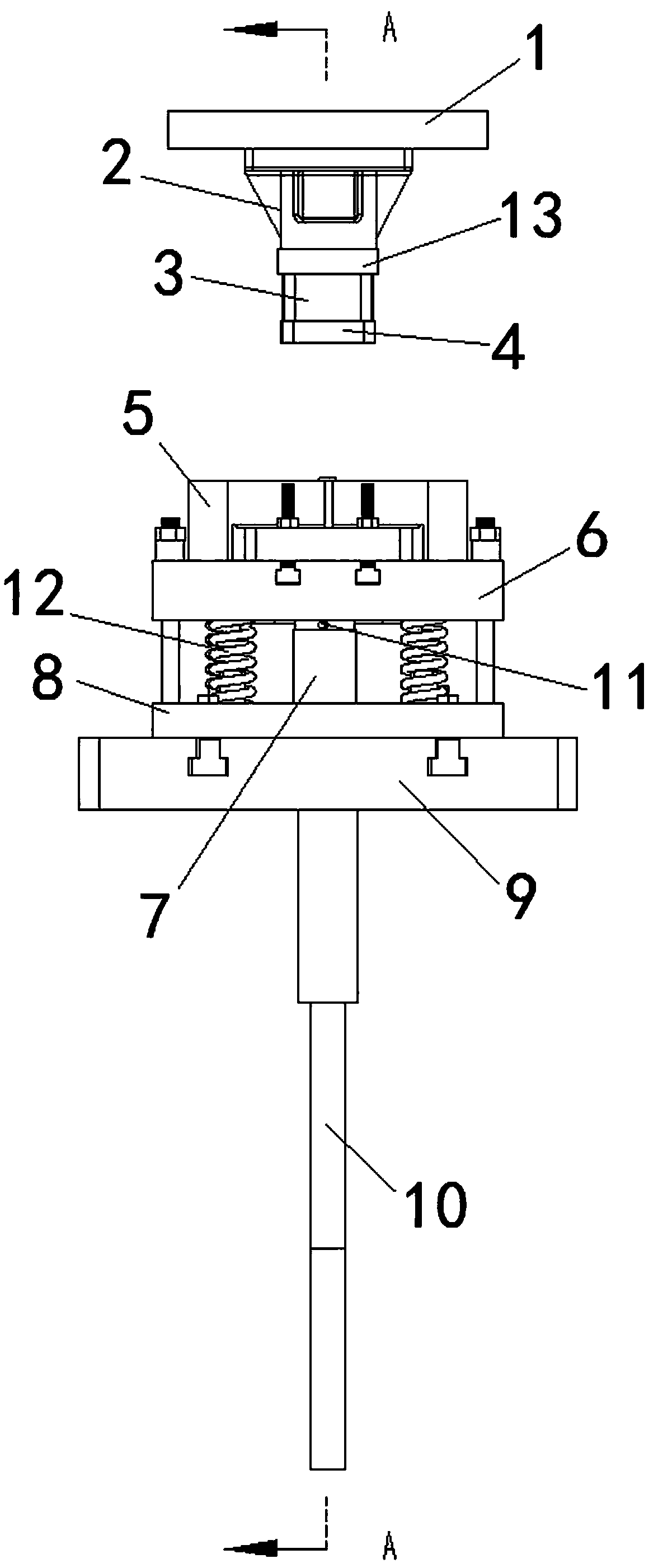

[0023] A kind of sliding brick pressing die of the present invention is mainly used to solve the sliding nozzle of the sub-compartment matching mode commonly used in China at present. Since the thickness of each part of the sliding brick is different, it is difficult to achieve the same material at the nozzle part. The performance of other materials is the same, but the strength of the mouth part is relatively poor. Using the brick pressing mold of the present invention, the common feeding method can be adopted, and the surface material can be made flat when distributing the materials. During the pressing process, the material at the bottom of the slit part is deep in the initial stage, and the slit depth of the normal brick adobe is restored in the middle and late stages, and the processing process can be used. The depth of the mold at the neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com