High bulging and high impact resistance magnesium alloy sheet and preparation method thereof

A technology of high impact resistance and magnesium alloy, applied in metal rolling, metal rolling, metal processing equipment, etc. The problem of high texture strength of the basal plane can achieve the effect of avoiding waste of resources and insufficient performance, large normal stress, and enhanced grain boundary strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

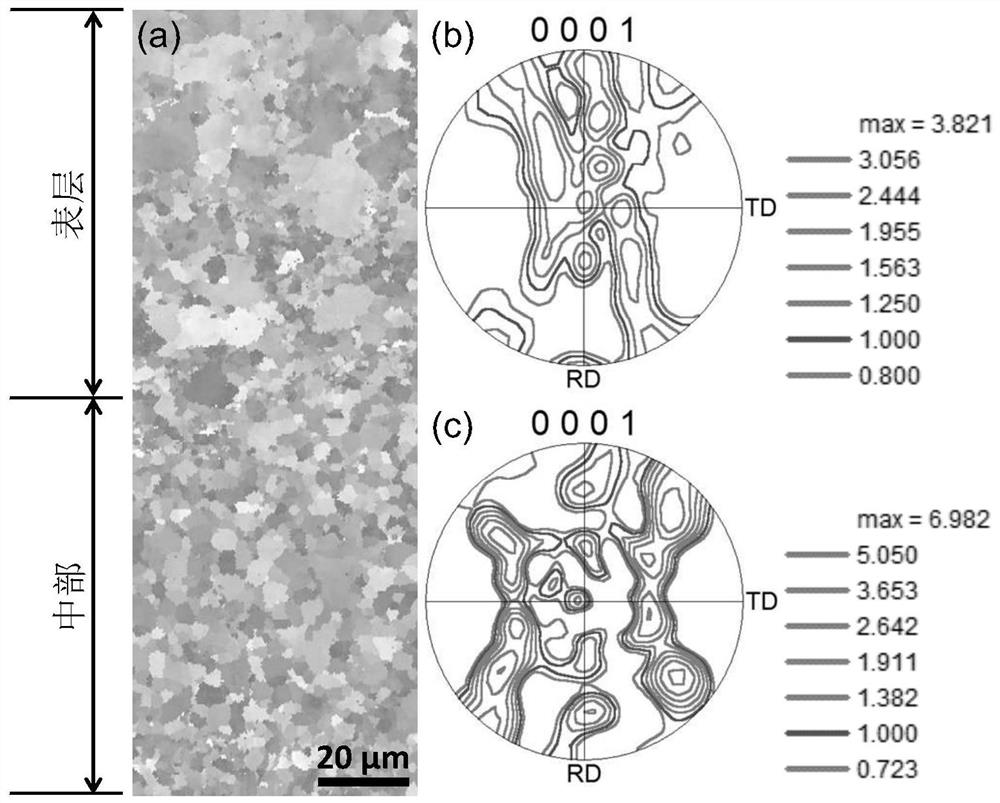

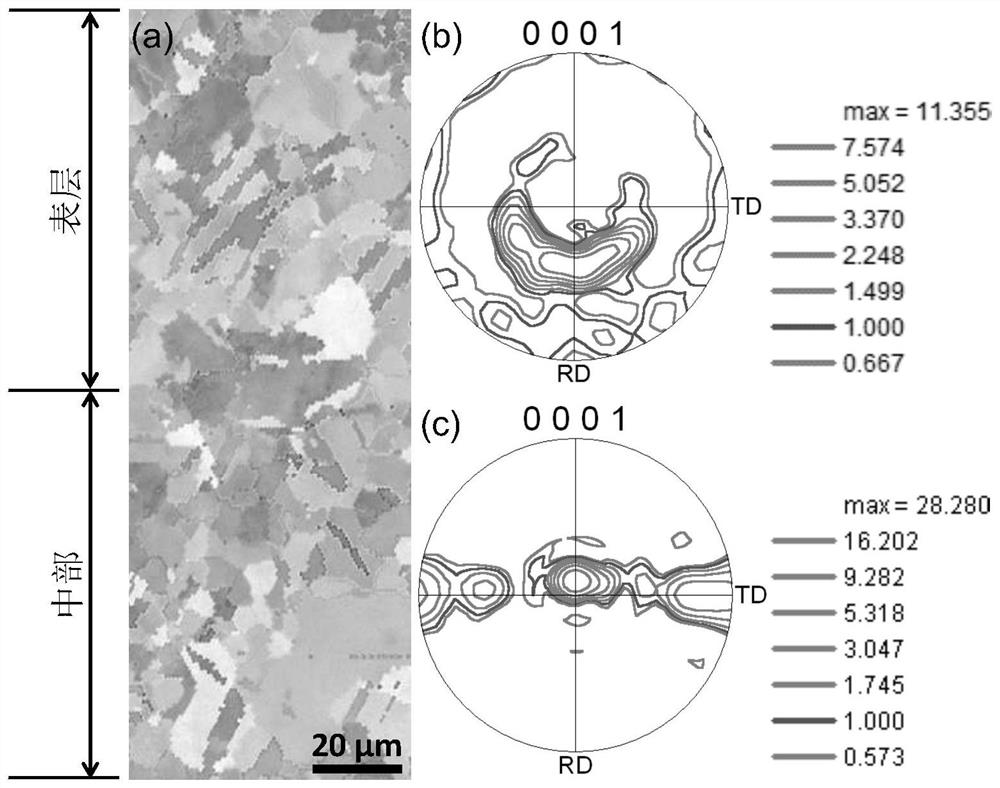

Image

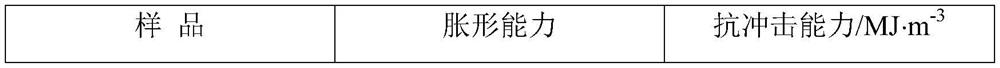

Examples

Embodiment 1

[0044] A magnesium alloy with high bulging property and high impact resistance contains 0.2% Co and 0.9% Zr by mass %, and the balance is Mg and unavoidable impurities, wherein the mass percentage ratio of Co to Zr is 0.22.

[0045] A magnesium alloy with high bulging property and high impact resistance of the present embodiment comprises the following steps:

[0046] The raw material is Mg-0.2Co-0.9Zr (mass percentage), cast into a magnesium alloy ingot billet, processed into a 5mm thick plate, and homogenized annealing; heat the plate to 250°C and roll to 550°C, and wait for the plate and roll Continuous rolling is carried out after uniform temperature, the reduction in each pass is 10%, and the total reduction is 30%. After the rolling, the plate is directly water quenched and subjected to stress relief annealing.

Embodiment 2

[0055] A magnesium alloy with high bulging property and high impact resistance contains 0.2% Sb and 0.2% Ca in mass percent, and the balance is Mg and unavoidable impurities, wherein the mass ratio of Sb to Ca is 1.

[0056] A preparation method of the high bulging and high impact resistance magnesium alloy of the present embodiment comprises the following steps:

[0057] According to the raw material Mg-0.2Sb-0.2Ca (mass percentage), cast a magnesium alloy ingot billet, process it into a 10mm thick plate, and homogenize annealing; heat the plate to 100°C and the roll to 450°C, and wait for the plate and the roll to be uniform After warming, continuous rolling is carried out, the reduction in each pass is 10%, and the total reduction is 60%. After the rolling, the plate is directly water quenched and subjected to stress relief annealing.

Embodiment 3

[0059] A magnesium alloy with high bulging property and high impact resistance, which contains 0.2% Sb, 0.1% Ca and 0.1% Zr by mass %, and the balance is Mg and unavoidable impurities, wherein the total mass percentage of Ca and Zr is 0.2% %, the mass ratio of Sb to the total amount of Ca and Zr is 1.

[0060] A kind of preparation method of the high bulging property high impact resistance magnesium alloy of this embodiment, the difference with embodiment 2 only lies in, the material composition is different, the raw material composition is Mg-0.2Sb-0.1Ca-0.1Zr ( mass percent).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com