A composite material opening analysis method considering BVID impact damage influence

A composite material and impact damage technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve problems such as engineering application restrictions, overly conservative design, and endangering the safety of aircraft structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings. The basic implementation process is as follows:

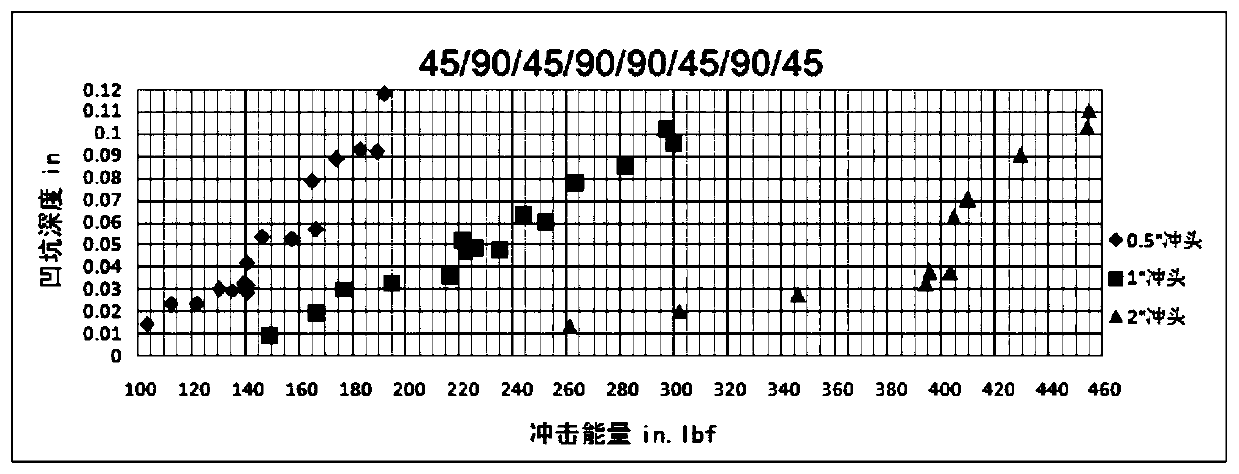

[0186] The first step: determine the impact energy required for the composite material to contain BVID, design the indentation depth investigation test, and determine the impact energy required for the laminates of different thicknesses and different layup sequences to produce a 2.5mm BVID dent before rebound. The laminate impact investigation test matrix is shown in Table 1, a total of 75 pieces, and the impact head diameters used are 12.7mm and 25.4mm. For each group of tests, three specimens are made with the same impact energy, and the damage size introduced is required to ensure the threshold value of the opening strength of the composite material. Provide the impact energy-dimple depth curve after the test, such as figure 1 shown. The introduction of impact damage is imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com