Film system design of reducing aberration generated because of observation angle changes and manufacturing method thereof

A technology of viewing angle and film system design, applied to optical components, optics, instruments, etc., can solve problems such as aggravating color uniformity and inevitable changes in interference results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

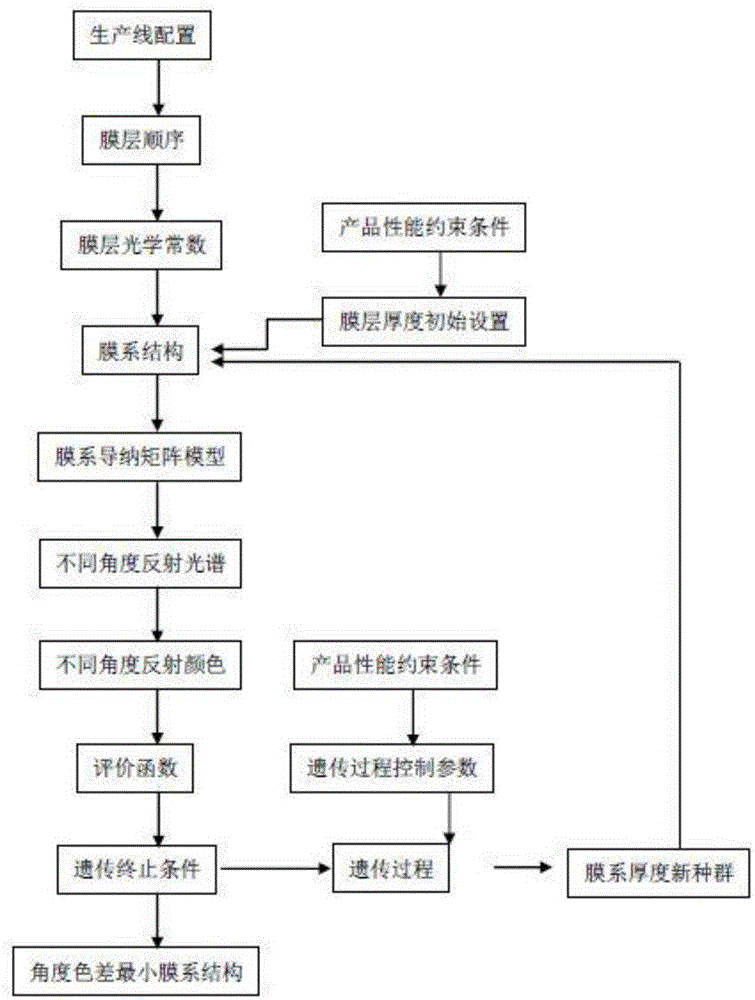

Method used

Image

Examples

Embodiment 1

[0053] An embodiment of the present invention proposes a film system design and preparation method to reduce the chromatic aberration caused by the change of the observation angle, taking magnetron sputtering plating large-area double silver offline low-emissivity coated glass as an example. Table 1 shows the target configuration of the production line Position, target configuration, and the film sequence determined, the substrate is architectural float glass with a thickness of 5.86mm; when using magnetron sputtering to coat the film of low-emissivity coated glass, Si:Al, Zn:Al are used , Zn:Sn alloy target reactive sputtering to generate the corresponding film SiN x , ZnO x , ZnSnO x , Use metal target sputtering to deposit the corresponding film layer Ag, NiCr.

[0054] Table 1 Production line double-silver configuration target target material and corresponding film sequence

[0055] order

1

2

3

4

5

6

7

8

9

10

Target

Si:Al

Zn:Al

Ag

NiCr

Zn:Sn

Zn:Al

Ag

NiCr

Zn:Sn

Si:Al

Fi...

Embodiment 2

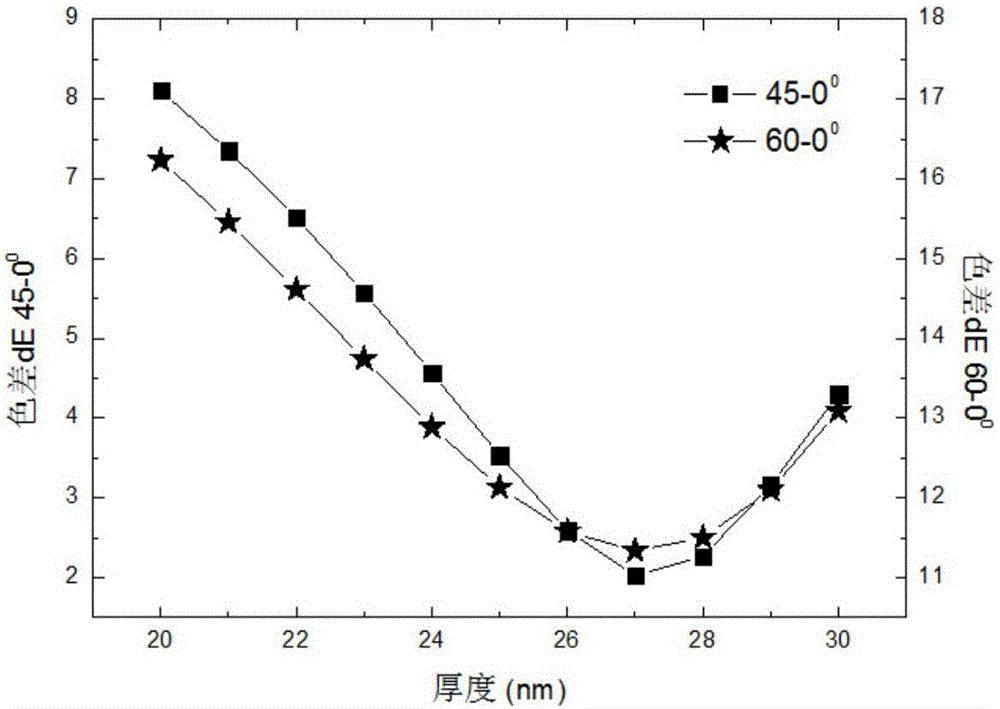

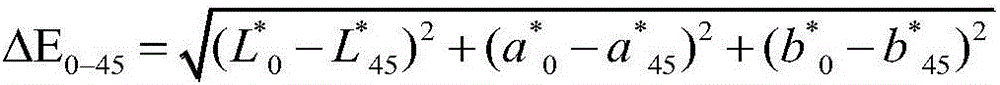

[0075] An embodiment of the present invention proposes a film system design and preparation method for reducing the chromatic aberration caused by the change of the observation angle. Taking magnetron sputtering plating large-area single silver offline low-emissivity coated glass as an example, the present invention proposes to reduce the observation The film system design method for chromatic aberration caused by the angle change is designed to optimize the film system performance. Table 7 shows the target position, target configuration and film structure of a blue-gray single silver coated glass production line with a transmittance greater than 50%. Initial design. Table 8 shows the performance results of the initial design single silver film system.

[0076] Table 7 Production line single silver configuration target position, target material and initial design of film system (thickness: nm)

[0077]

[0078] Table 8 Initial design single silver film performance

[0079]

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com