New energy electric vehicle

A technology of electric vehicles and new energy, applied in the direction of bumpers, etc., can solve the problems of frame deformation and poor side impact ability, and achieve the effect of good anti-side impact ability, not easy to deform, and increase the factors involved in energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

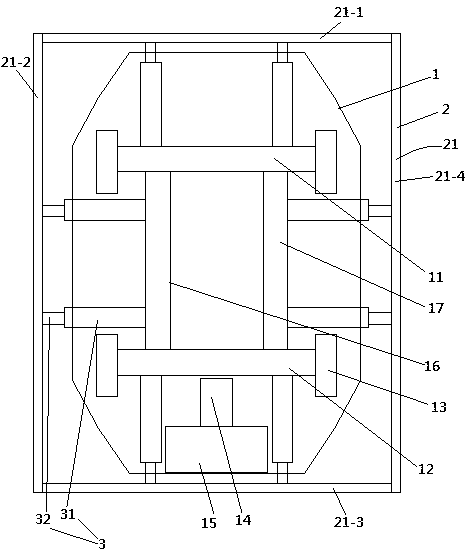

[0025] Embodiment one, see figure 1 , a new energy electric vehicle, comprising a car body 1, a safety ring 2 and an energy-absorbing cylinder 3. The vehicle body 1 is supported on a front axle 11 and a rear axle 12 through a suspension system. Both ends of the front axle 11 and the rear axle 12 are connected with wheels 13 . The vehicle body 1 is also provided with a drive motor 14 for driving the electric vehicle to walk and a power supply 15 for supplying power to the drive motor.

[0026] The safety ring 2 is wound around the vehicle body 1 and protrudes from the vehicle body 1 in the horizontal direction. The insurance ring 2 is composed of four bumpers 21 connected end to end in sequence, and the four bumpers 21 are respectively a front bumper 21-1, a left bumper 21-2, a rear bumper 21-3 and a right bumper 21-4 . A left longitudinal load-bearing beam 16 and a right longitudinal load-bearing beam 17 are connected between the front axle 11 and the rear axle 12 . The f...

Embodiment 2

[0032] Embodiment two, the difference with embodiment one is:

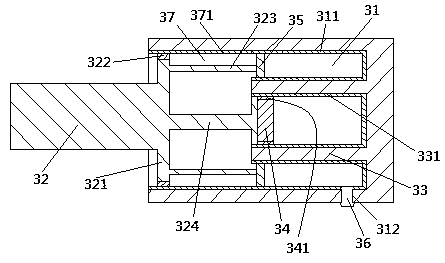

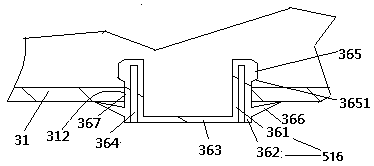

[0033] see Figure 4 , The inner peripheral surface of the circular inner tube 361 is provided with a guide vane 368 that guides the plug 36 to rotate when the fluid flows through the circular inner tube. The compression cylinder 31 is also provided with a support frame 38 . The support frame 38 is rotatably connected with the knife seat 39 of the circular tube structure through the plane bearing 381 . The knife seat 39 is connected with an annular knife body 391 . A limiting portion 392 is formed between the knife body 391 and the knife seat 39 . The cutter body 391 is provided with a cutting edge 393 . The cutting edge 393 is aligned with the base plate 363 . The outer diameter of the cutter body 391 is equal to the inner diameter of the circular inner tube 361 .

[0034] From the use process, if the plug 36 ejects, before the cutting edge 393 contacts with the base plate 363, the knife seat 39 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com