Slope supporting structure and method

A technology for supporting structures and slopes, which is used in basic structure engineering, excavation, construction, etc., can solve problems such as failure to meet design requirements, difficulty in achieving design effects with tensile stress, and achieve improved slope protection effects and good slope protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

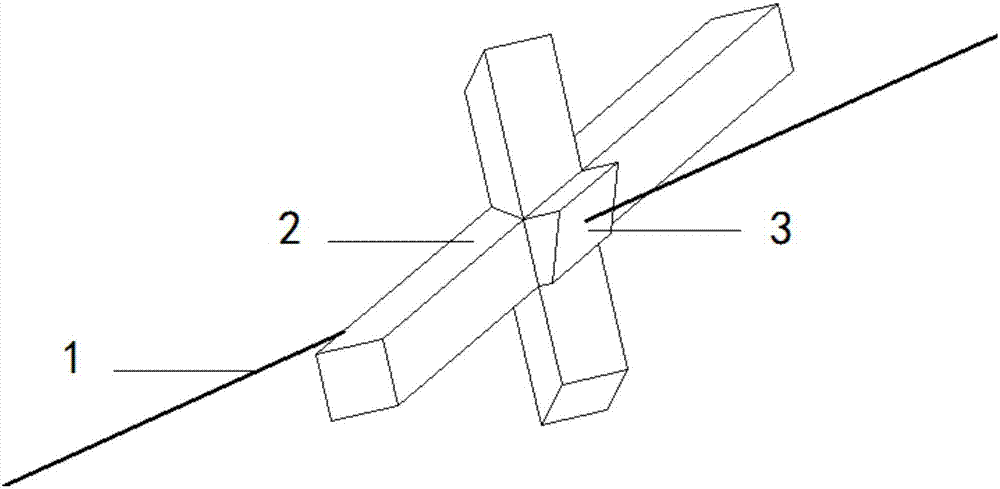

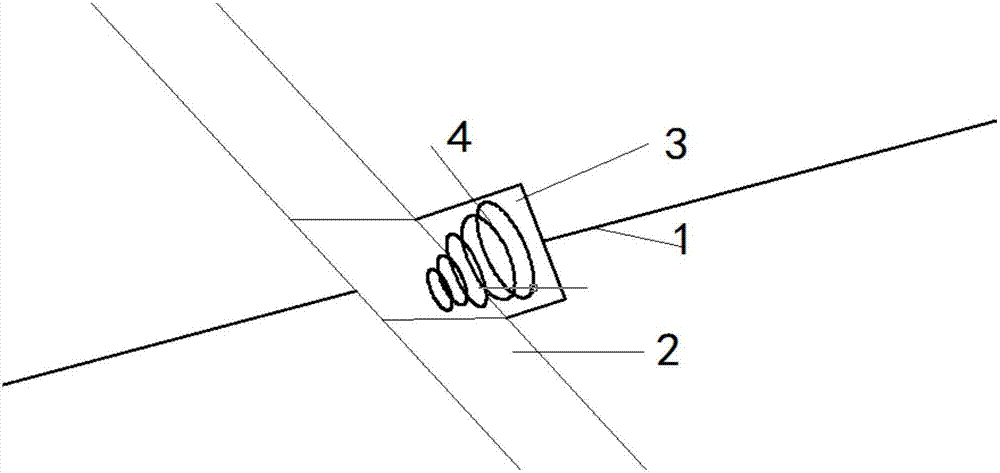

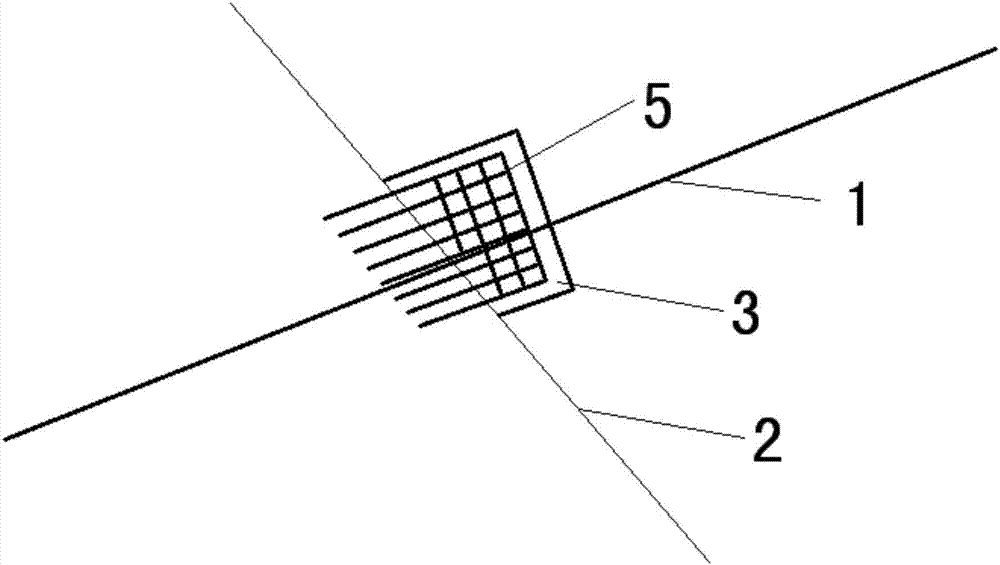

[0028] Such as Figure 1-Figure 3 , a slope support structure, comprising a prestressed anchor cable 1 and a sash beam 2 arranged on the slope surface, a pedestal 3 is arranged on the surface of the intersection of the sash beam 2, and a spiral bar is embedded in the pedestal 3 4. One end of the spiral rib 4 extends to the sash beam 2 and connects with the steel skeleton of the sash beam 2 , and the other end of the spiral rib 4 is embedded in the pedestal 3 . The prestressed anchor cable 1 vertically passes through the spiral reinforcement 4 and the pedestal 3, and the pedestal 3 is located around the spiral reinforcement 4. There is also an encrypted steel skeleton 5, and one end of the encrypted steel skeleton 5 extends into the frame beam 2 and connects with the frame beam 2. steel frame connections.

[0029] Further, the pedestal 3 is a wedge-shaped body with an inclined upper surface, and the inclination angle of the inclined surface of the pedestal 3 relative to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com