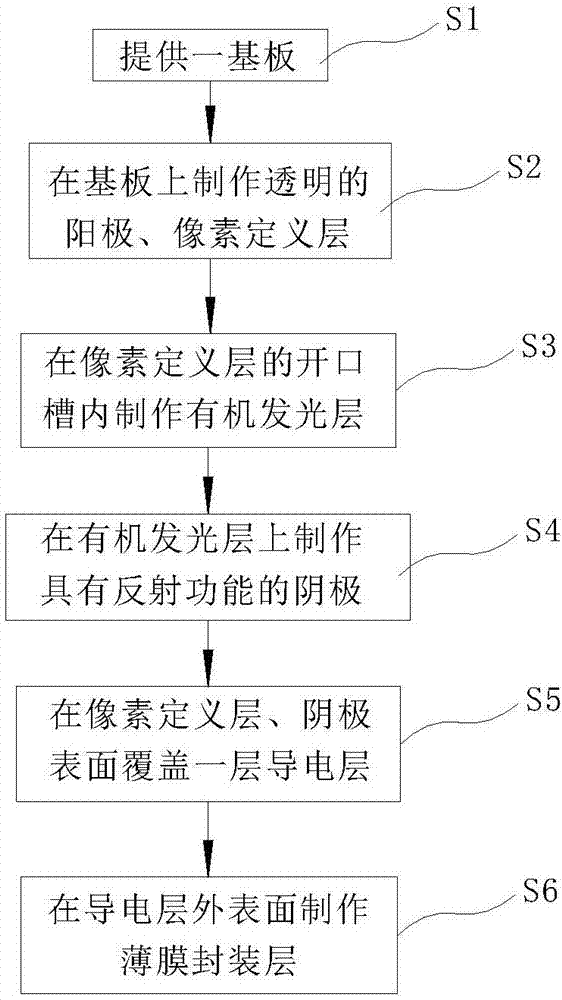

Organic light-emitting display panel and production method thereof

By making a reflective cathode in the light-emitting area of the OLED display panel and avoiding its presence in the non-light-emitting area, the problem of color purity reduction and color shift caused by light reflection in the bottom-emitting device is solved, and the display effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] refer to figure 1 The bottom-emission organic light-emitting display panel of this embodiment includes a substrate 10, a transparent anode 20 located on the substrate 10, a pixel definition layer 30, an organic light-emitting layer 40, and several cathodes 50 with reflective functions. The pixel definition layer 30 is provided with A plurality of open grooves, one end of the open groove close to the substrate 10 is arranged on the anode 20, the organic light-emitting layer 40 is filled in the open groove, the cathode 50 is arranged on the organic light-emitting layer 40 and accommodated in one end of the open groove away from the substrate 10, each opening The two ends of the tank correspond to an anode 20 and an anode 20 respectively.

[0026] In order to realize that all the cathodes 50 are electrically connected to each other, so as to facilitate the transmission of electrical signals, a conductive layer 60 is formed on the surface of the cathode 50 in this embodimen...

Embodiment 2

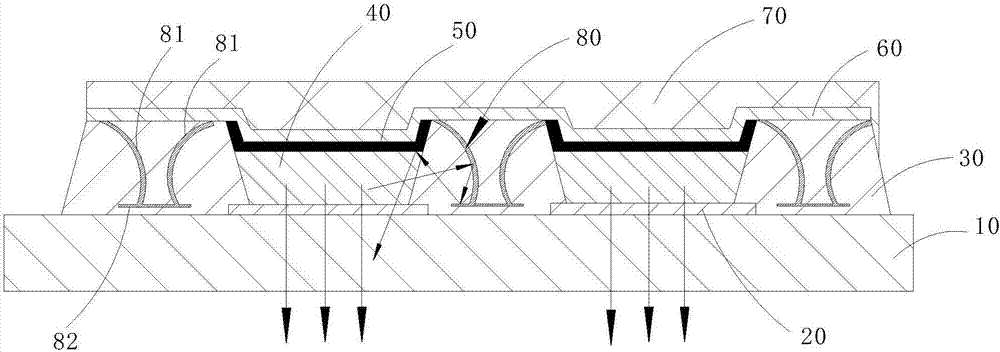

[0039] like image 3 As shown, the difference from Embodiment 1 is that the bottom emission organic light emitting display panel of this embodiment also has a reflector 80, and the reflector 80 is arranged in the pixel definition layer 30 for directing the incident light toward the adjacent organic light emitting display panel. The luminescent layer 40 is reflective.

[0040] The reflector 80 specifically includes a first reflective portion 81 whose reflective surface is a concave arc surface, the first reflective portion 81 is a rotating body, and a second reflective portion 82 covering the end face of the first reflective portion 81, the second reflective portion Edges 82 extend from the end surface of the first reflective portion 81 toward the surroundings. Part of the light emitted from the organic light-emitting layer 40 into the pixel definition layer 30 is reflected back to the organic light-emitting layer 40 by the first reflective portion 81, and part of the light is...

Embodiment 3

[0042] like Figure 4 As shown, the difference from Embodiment 2 is that the reflection member 80 of this embodiment includes a cylindrical reflection ring perpendicular to the substrate 10 . The reflective ring can reflect back the light emitted from the surrounding adjacent organic light-emitting layers 40 , preventing interference between adjacent pixels and improving the utilization rate of the light source.

[0043]In the bottom-emitting organic light-emitting display panel of the present invention, the cathode with reflection function is only fabricated in the light-emitting area, and the cathode with reflection function is not fabricated in the non-light-emitting area, which can effectively prevent the light emitted from the sub-pixel from interfering with adjacent pixels in the bottom light-emitting device. sub-pixels, thereby improving color purity and improving color cast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com