Automobile wire harness plug-in having terminal anticreep function

A technology for automotive wiring harnesses and terminals, which is applied to parts, electrical components, and fixed/insulated contact members of connecting devices, etc., can solve problems such as loosening, separation of two plug-ins, and plug-in separation, so as to prevent fatigue damage of shrapnel and improve plug-in The effect of connection stability, quick disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

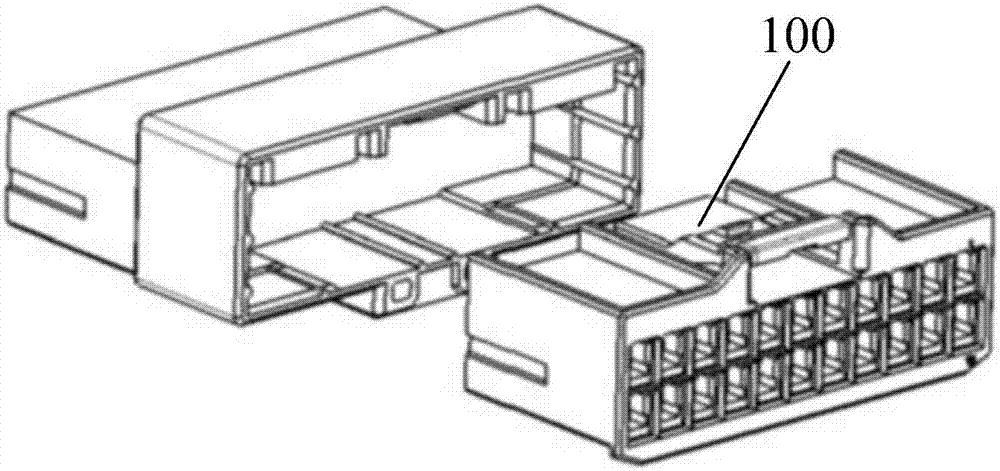

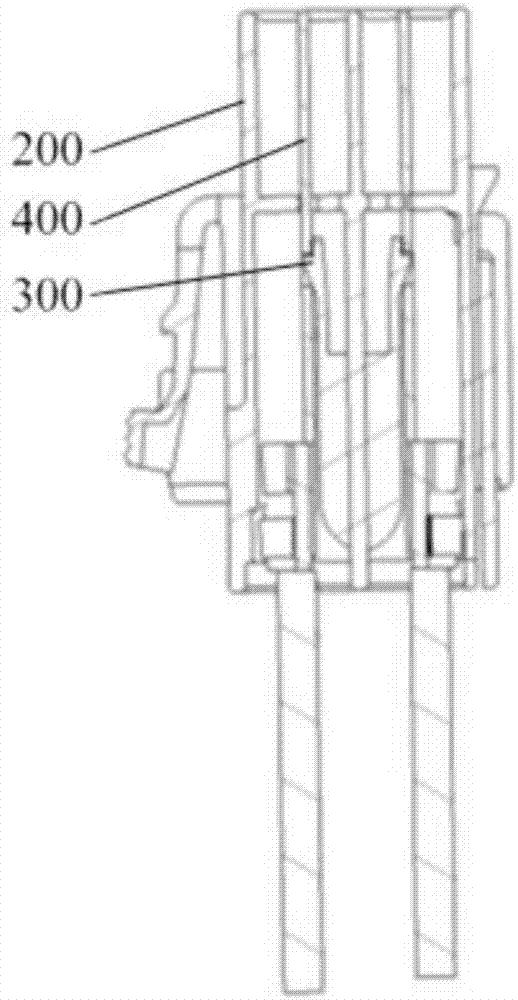

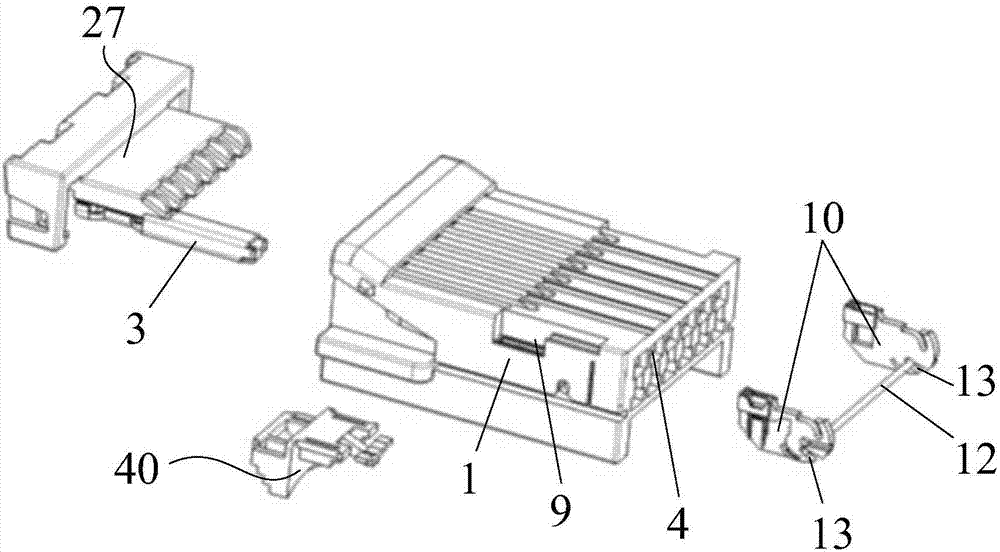

[0042] Embodiments of the present invention: as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, an automobile wiring harness plug-in with terminal detachment prevention function includes a plug-in body 1, a first elastic piece 2 and a terminal 3. The plug-in body 1 is provided with several terminal installation holes 4 arranged at equal intervals and with the same structure. The hole 4 is a through hole through the plug-in body 1. One end of the terminal installation hole 4 is provided with a shrapnel mechanism 5. The top of the shrapnel mechanism 5 is provided with a clamping boss 6, and the bottom is provided with a semicircular hook-shaped part 7. Each A terminal 3 is installed in each terminal mounting hole 4, and the bottom of the terminal 3 has a limit hole 8 that cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com