Digital temperature compensation method of crystal oscillator

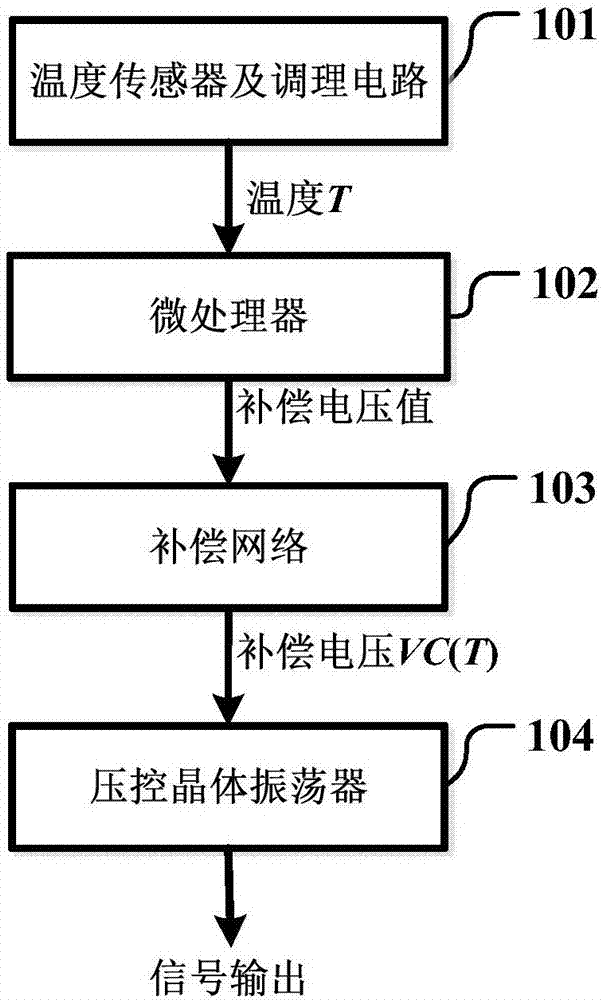

A digital temperature compensation, crystal oscillator technology, applied in the direction of output stability, electrical components, etc., can solve the problems of temperature hysteresis of temperature sensor and resonant chip, limited compensation accuracy, failure to make breakthroughs, etc., to achieve easy integration and mass production, Good compensation effect, easy real-time high-precision compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

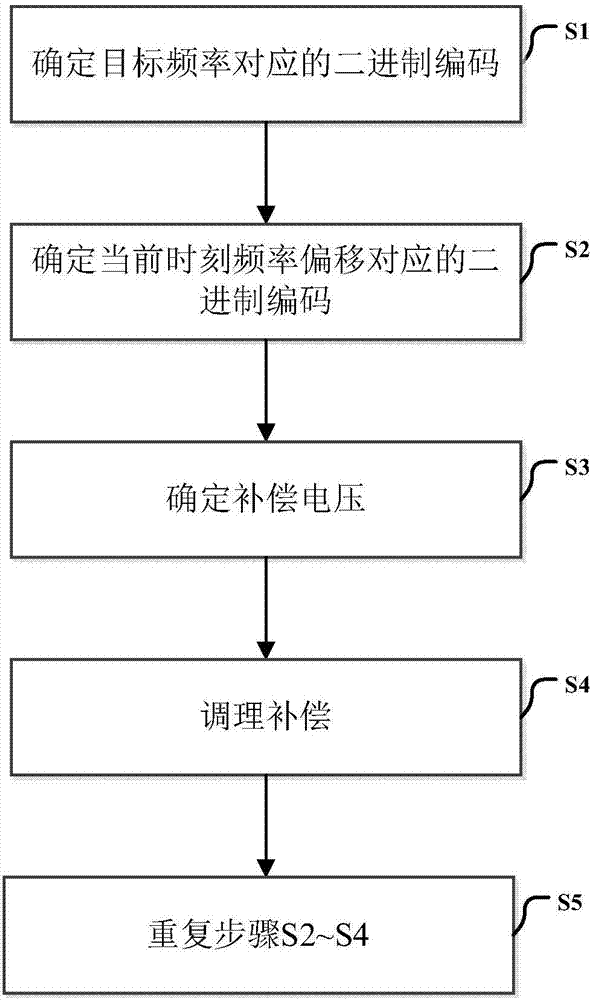

[0040] image 3 It is a specific implementation flowchart of the digital temperature compensation method of the crystal oscillator of the present invention.

[0041] In this example, if image 3 As shown, the digital temperature compensation method of the crystal oscillator of the present invention comprises the following steps:

[0042] Step S1: Determine the target frequency f 0 Corresponding binary code B 0i

[0043] at room temperature T 0 , such as at 25°C, adjust the control voltage of the voltage-controlled crystal oscillator, that is, the voltage control termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com