Soybean milk machine

A technology of soymilk machine and machine head, applied in milk substitutes, dairy products, applications, etc., can solve the problems of motor working time cannot be further reduced, waste time and energy, motor noise, etc., to increase the crushing effect, avoid waste, reduce Effect of motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

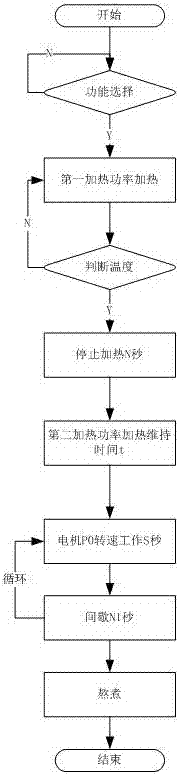

[0019] The present invention provides a soymilk maker, which comprises a machine head and a cup body, the machine head is fastened on the cup body, a motor is arranged inside the machine head, and the motor shaft of the motor extends into the cup body, The front end of the motor shaft is provided with a crushing cutter. The material in the cup is heated to a predetermined temperature with the first heating power, and heated with the second heating power for a time t, and the pulverizing tool starts pulverizing the material at a rotational speed P0.

[0020] In this embodiment, the cup body is provided with a heating device, and the machine head is provided with other corresponding detection devices such as a temperature detection device and an overflow detection device. Of course, the soymilk machine also includes a corresponding control device, which is connected with the detection device, detects the operating parameters of the soymilk machine, and adjusts the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com