Mud sand separation device used for water conservancy projects

A technology for sediment separation and water conservancy engineering, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of waste of processing resources, high maintenance and repair costs, complicated procedures, etc., and achieve smooth processing and easy repair and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

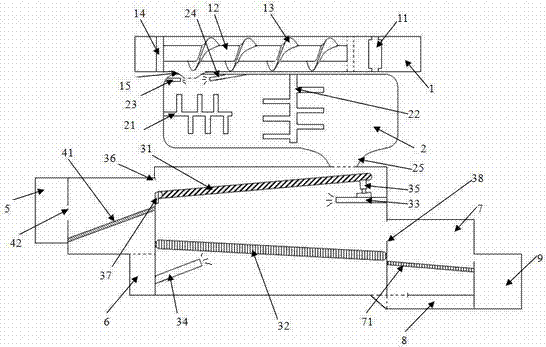

[0034] Such as figure 1 Shown:

[0035] A sediment separation device for water conservancy projects, comprising a sediment transfer chamber, a stirring mixing chamber, a sediment separation chamber, a sludge filter box, a sand filter box, a sludge collection box, a sand collection box, a first water collection box and a second water collection box collection box.

[0036] The sediment conveying chamber is a horizontal cylinder as a whole, and a dredge pump is arranged at the entrance for sucking the sediment produced in the water conservancy project, and a conveying shaft is arranged laterally on the side of the dredge pump away from the inlet , a spiral broken piece made of hard alloy is arranged on the transmission shaft, a terminal plug is provided at the other end of the transmission shaft, and a driving motor for driving the rotation of the transmission shaft is provided on the rear side of the terminal plug. The lower side of the transmission shaft on the side of the t...

Embodiment 2

[0058] A sediment separation device for water conservancy projects, comprising a sediment transfer chamber, a stirring mixing chamber, a sediment separation chamber, a sludge filter box, a sand filter box, a sludge collection box, a sand collection box, a first water collection box and a second water collection box collection box.

[0059] The sediment conveying chamber is a horizontal cylinder as a whole, and a dredge pump is arranged at the entrance for sucking the sediment produced in the water conservancy project, and a conveying shaft is arranged laterally on the side of the dredge pump away from the inlet , a spiral broken piece made of hard alloy is arranged on the transmission shaft, a terminal plug is provided at the other end of the transmission shaft, and a driving motor for driving the rotation of the transmission shaft is provided on the rear side of the terminal plug. The lower side of the transmission shaft on the side of the terminal plug is provided with an ou...

Embodiment 3

[0080] A sediment separation device for water conservancy projects, comprising a sediment transfer chamber, a stirring mixing chamber, a sediment separation chamber, a sludge filter box, a sand filter box, a sludge collection box, a sand collection box, a first water collection box and a second water collection box collection box.

[0081] The sediment conveying chamber is a horizontal cylinder as a whole, and a dredge pump is arranged at the entrance for sucking the sediment produced in the water conservancy project, and a conveying shaft is arranged laterally on the side of the dredge pump away from the inlet , a spiral broken piece made of hard alloy is arranged on the transmission shaft, a terminal plug is provided at the other end of the transmission shaft, and a driving motor for driving the rotation of the transmission shaft is provided on the rear side of the terminal plug. The lower side of the transmission shaft on the side of the terminal plug is provided with an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com