Centering and rotating device for assembly of high-pressure compressor of aero-engine

An aero-engine and rotating device technology, which is applied to workpiece clamping devices, aircraft parts, transportation and packaging, etc., can solve the problems of affecting the inspection quality, inflexible rotor rotation, and unadjustable centering structure, and achieves convenient assembly and disassembly. Good detection conditions, flexible rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

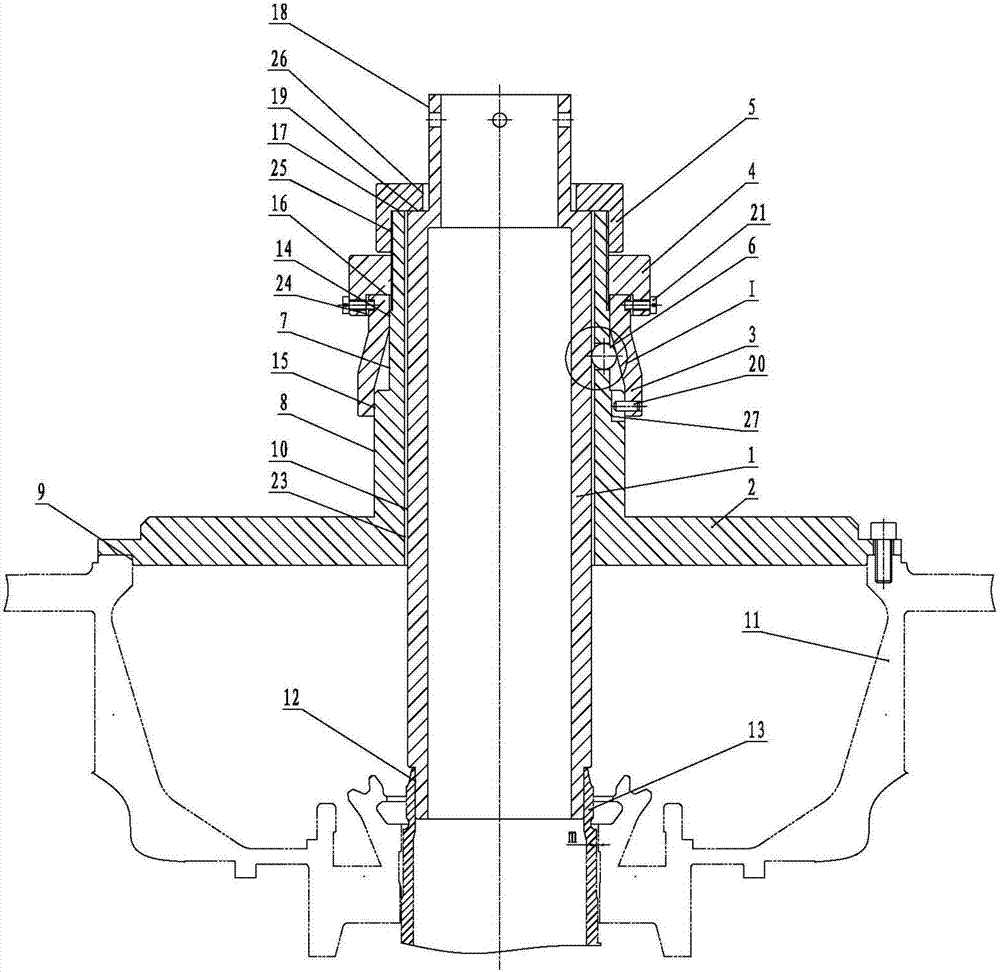

[0016] Below the present invention is described in further detail, see figure 2 and image 3 , the size of the reference hole of the compressor housing 11 is ф420mm, and the size of the center hole of the rotor 13 is ф100mm. The aeroengine high-pressure compressor of the present invention is assembled with a centering and rotating device, which includes: a mandrel 1, a base mandrel 2. Adjusting sleeve 3, adjusting nut 4, compression nut 5, 3 steel balls 6, positioning pin 20, 4 set screws 21 and screws.

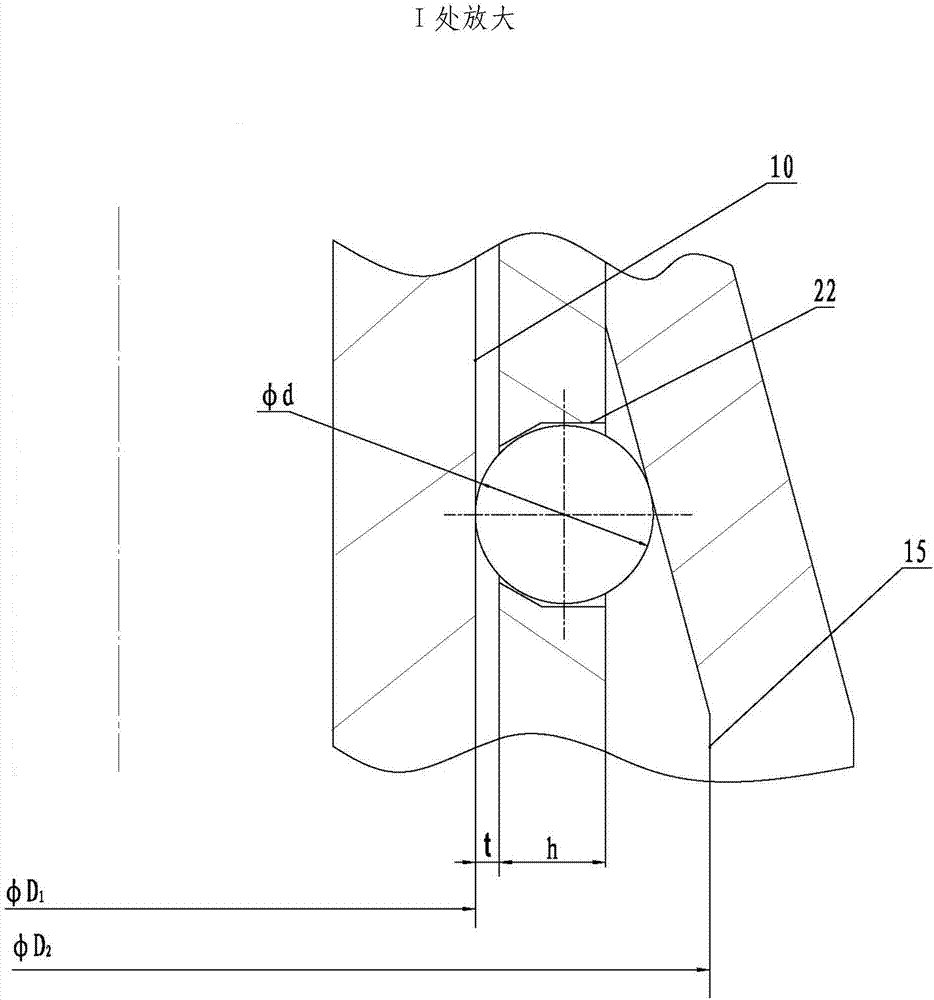

[0017] The mandrel 1 is composed of three concentric cylinders with different diameters, and the lowest cylindrical section I12 and the center hole of the rotor 13 ensure the interference fit of H7 / p6. Connected with the cylindrical section I12 is the centering cylindrical section 10, the diameter of the centering cylindrical section 10 is D 1 =110mm, the diameter difference between the centering cylinder section 10 and the cylinder section I12 forms a step surface; the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com