An automatic leveling instrument automatic assembly system

An automatic leveling and assembly system technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that restrict the production efficiency of automatic leveling instruments, the complex structure of the core component compensator, and the low degree of automation. The effect of addressing deficiencies and limitations, ensuring accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

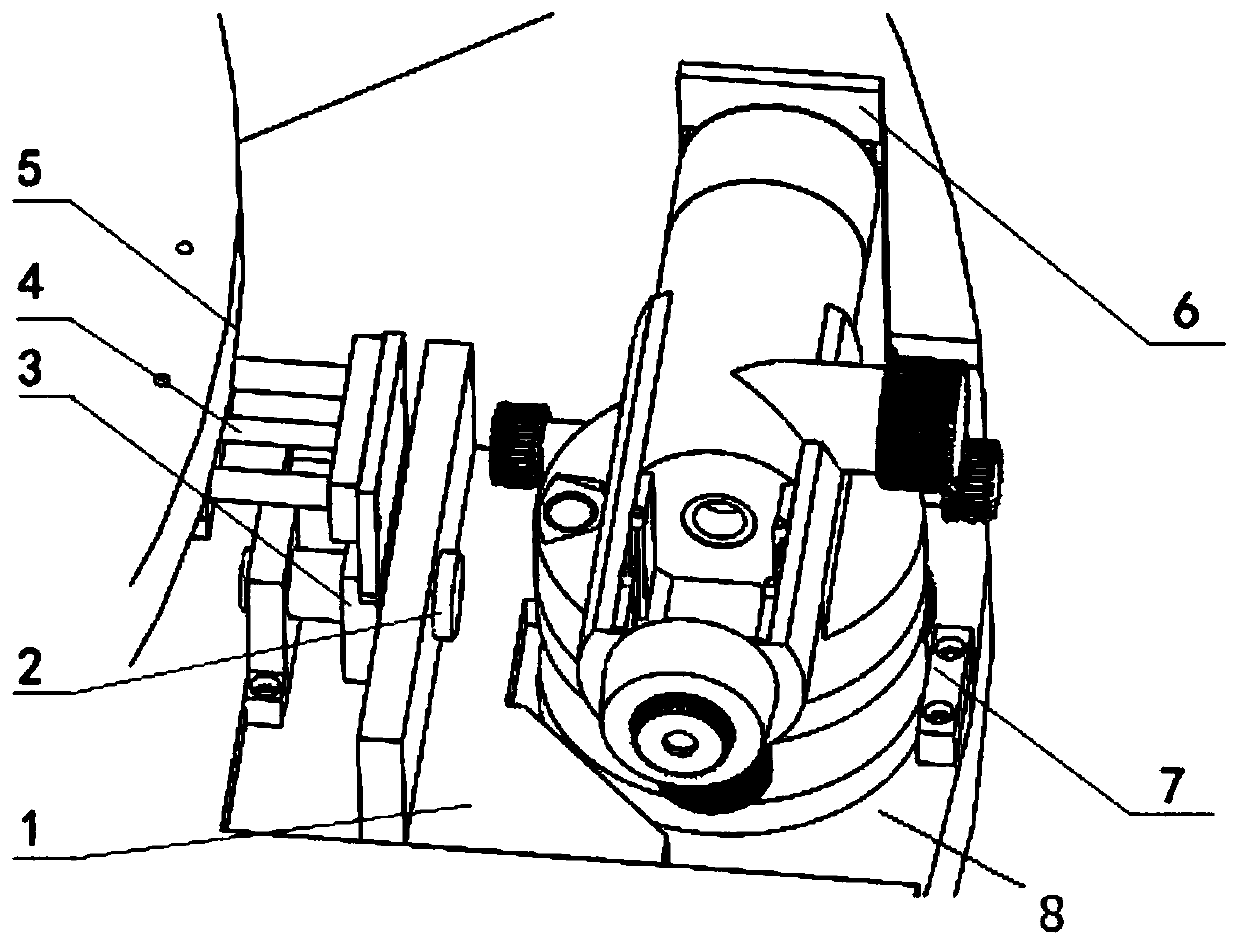

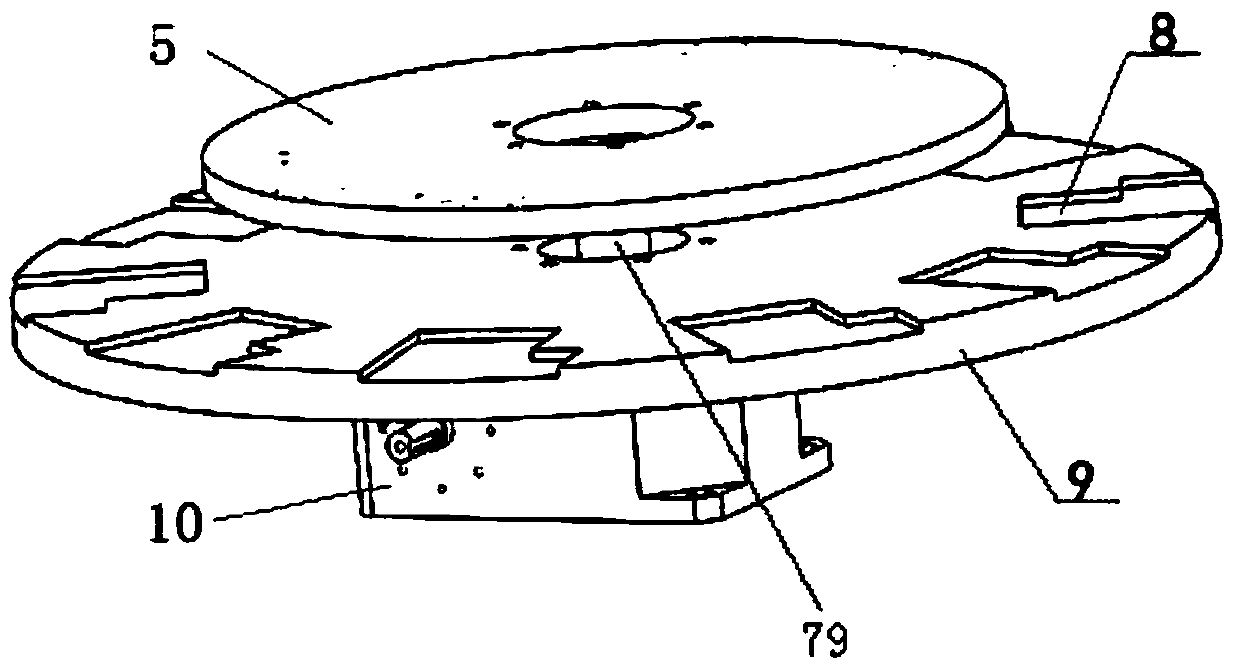

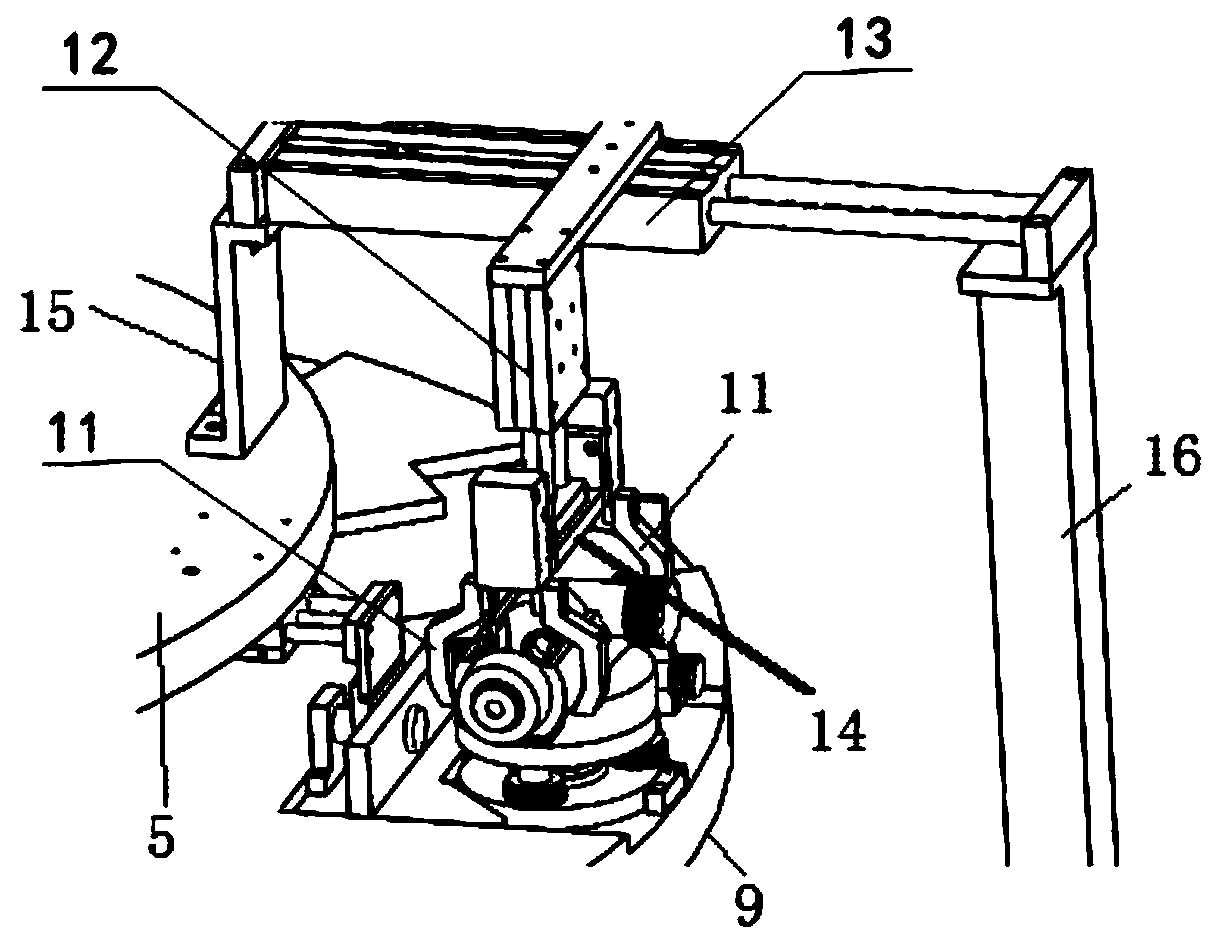

[0043] Depend on Figure 1-Figure 9 The shown automatic leveling automatic assembly system includes an upper fixed support plate 5, a lower rotating support plate 9 driven by a rotating shaft 79, several clamps and a substrate feeding mechanism 83 arranged on the lower rotating support plate 9.

[0044] The upper fixed support plate 5 and the lower rotating support plate 9 are arranged at intervals up and down, the upper fixed support plate 5 is arranged above the lower rotating support plate 9 at intervals, and the upper fixed support plate 5, the lower rotating support plate 9 and the rotating shaft 79 are coaxially arranged , the upper fixed support disc 5 and the lower rotary support disc 9 are horizontal discs, the rotating shaft 79 is vertically arranged, the central axis of the upper fixed support disc 5, the central axis of the lower rotary support disc 9 and the central axis of the rotating shaft 79 coincide, The lower rotating support disc 9 is provided with a centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com