Device for mounting interference fit pin shafts in drawing manner and method for mounting interference fit pin shafts

A technology of interference fit and pin shaft, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of low installation accuracy, difficulty in installation, and low installation efficiency, so as to reduce auxiliary requirements and difficulties, and achieve high installation efficiency. The smooth effect of the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A device A for installing interference-fit pin shafts in a pull-out manner and a method for installing interference-fit pin shafts:

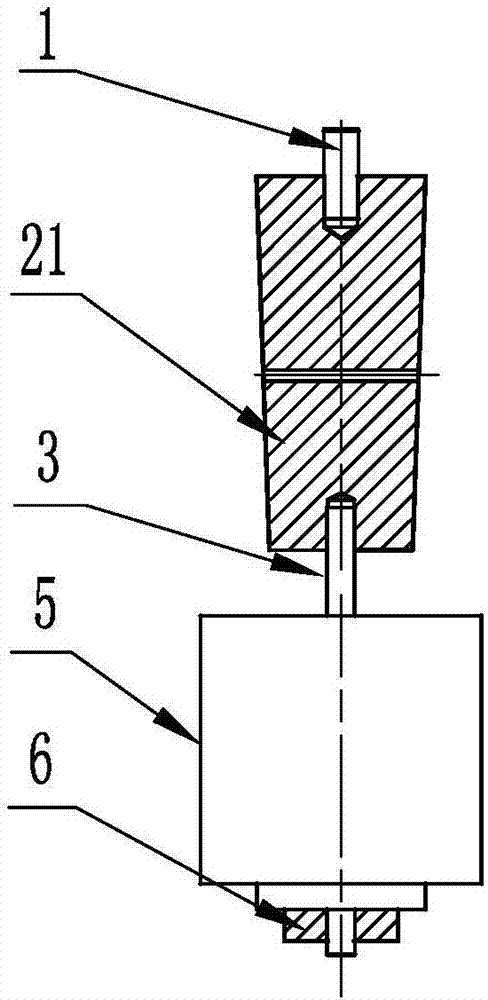

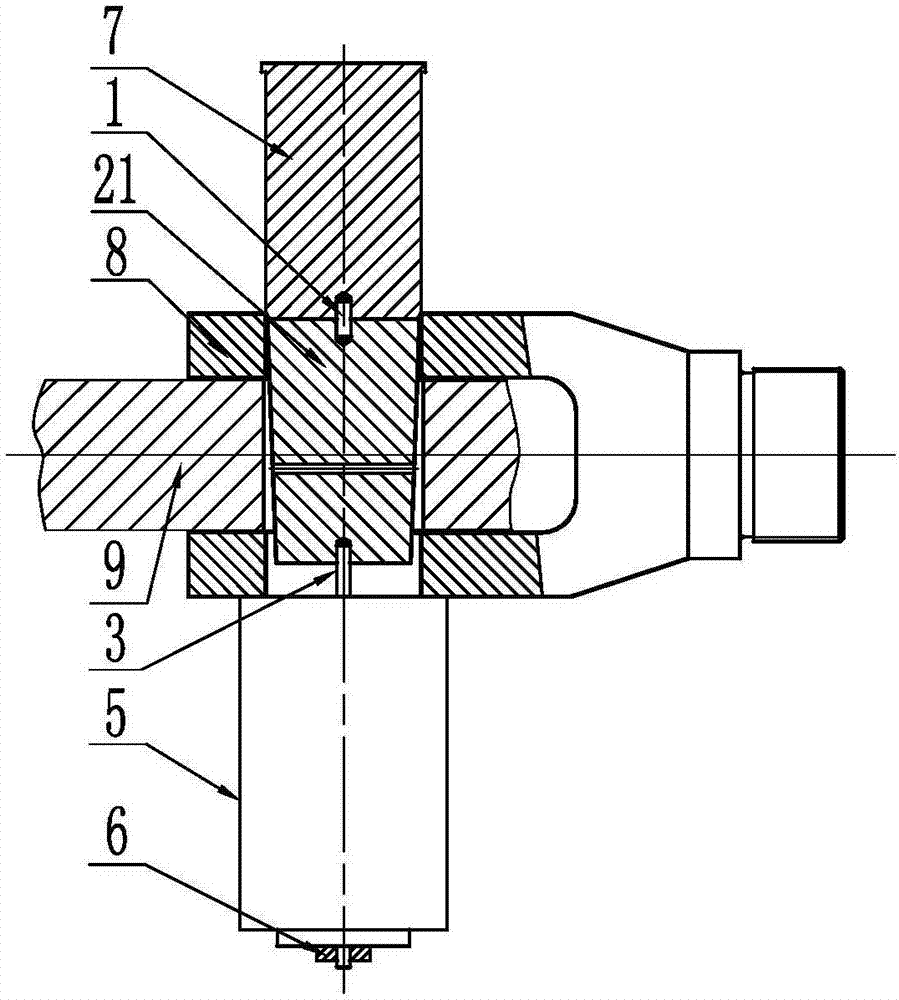

[0076] like figure 1 As shown, the basic structure of the device A of the pull-type installation interference fit pin includes a draw bar, a tension rod, a jack 5 and a nut 6, and it also includes a screw 1;

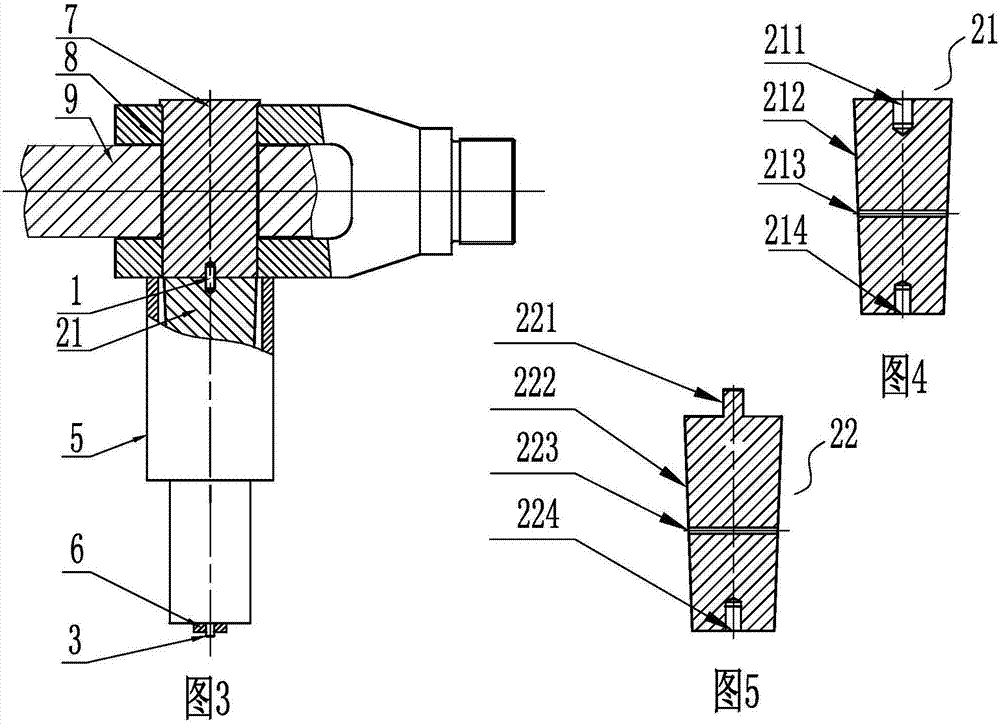

[0077] Described drawing rod is the drawing rod I21 (referring to Figure 4 ), under working condition, one end of the screw 1 is connected with the threaded hole 211 in the center of the large end face of the drawbar I21, and the other end of the screw 1 is connected with the pin 7 through the threaded hole on the pin 7; the thread in the center of the small end of the drawbar The hole is connected with the threaded end 31 of the tension rod II3b or tension rod I3a; the tension rod passes through the installation hole of the fork lug and the pin shaft, so that the tapered surface of the draw rod snaps into the installation hole of...

Embodiment 2

[0082] A device B for pulling and installing interference fit pins:

[0083] like Figure 7 As shown, its basic structure includes draw bar, tension bar, jack 5 and nut 6;

[0084] The drawbar is a drawbar II22 with a raised connecting thread 221 in the center of its large end face (see Figure 5 ), in the working state, the connecting thread 221 protruding from the center of the large end face of the draw rod II is connected with the pin shaft 7 through the threaded hole on the pin shaft 7; The threaded end 31 is connected; the tension rod passes through the installation hole of the fork lug and the pin shaft, so that the tapered surface of the draw rod snaps into the installation hole of the fork lug; the tension rod passes through the jack 5, and passes through the tension rod II3b or tension rod I3a Pull thread end 33 is connected with nut, and the bottom end of jack 5 is pressed on the fork lug (referring to Figure 8 ).

[0085] The basic steps of the method of using...

Embodiment 3

[0088] A device C for pulling and installing interference fit pins:

[0089] like Figure 10 As shown, the basic structure of the device C of the pull-type installation interference fit pin is the same as that of the first embodiment, including a screw 1, a draw bar, a tension bar 3, a jack 5 and a nut 6, and the draw bar is its large end surface Drawbar I21 with threaded hole 211 in the center (see Figure 4 ), differs from Embodiment 1 in that:

[0090] It also includes a support foot 4. Under the working condition, the tension rod 3 passes through the support foot 4 and the jack 5, and is connected with the nut through the tension thread end 33 of the tension rod II 3b or the tension rod I 3a, so that the bottom end of the support foot 4 is pressed on the On the fork lug, the bottom end of the jack 5 is pressed on the support foot 4 (see Figure 11 ).

[0091] The basic steps of the method of using the device C for installing interference fit pin shafts in a pull-out ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com