Woven bag grabbing mechanism, system and method

A technology of woven bags and toggle mechanism, which is applied in packaging and other directions, can solve the problems that woven bags cannot be grasped, and achieve the effect of increasing the bag supply speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

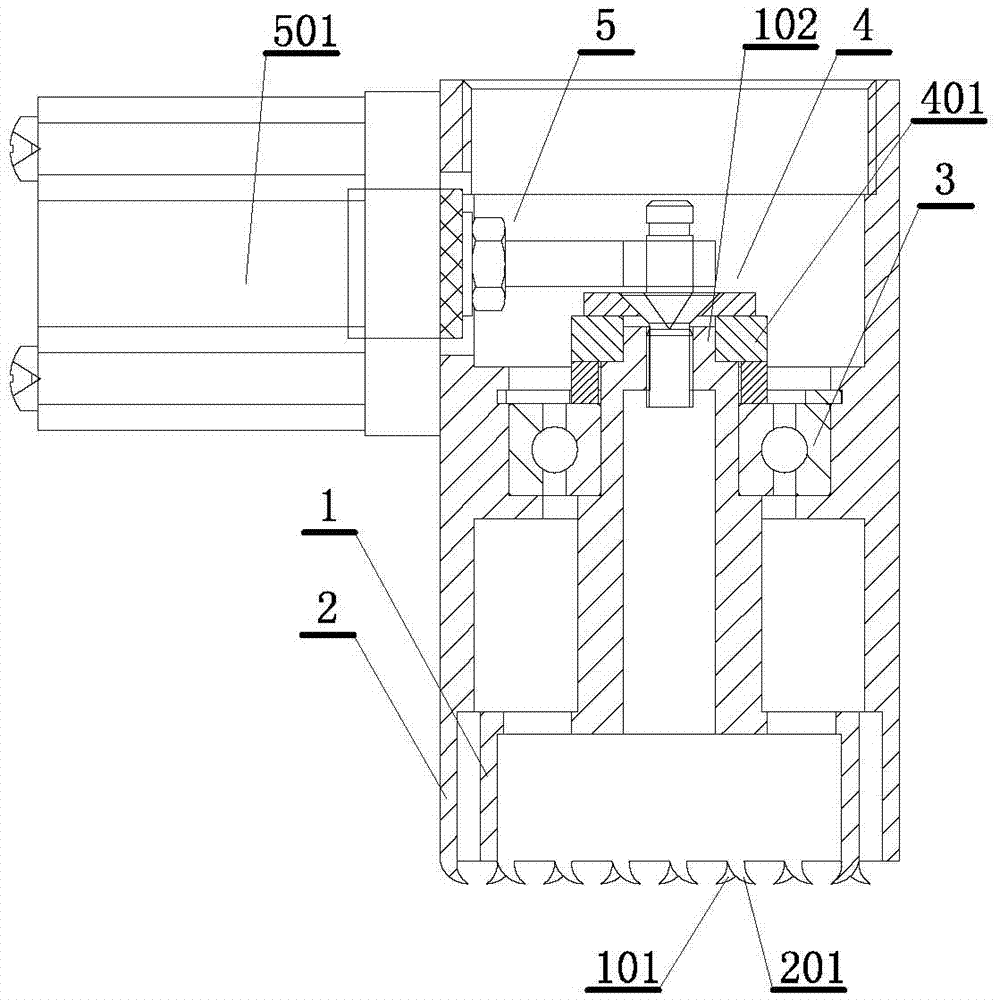

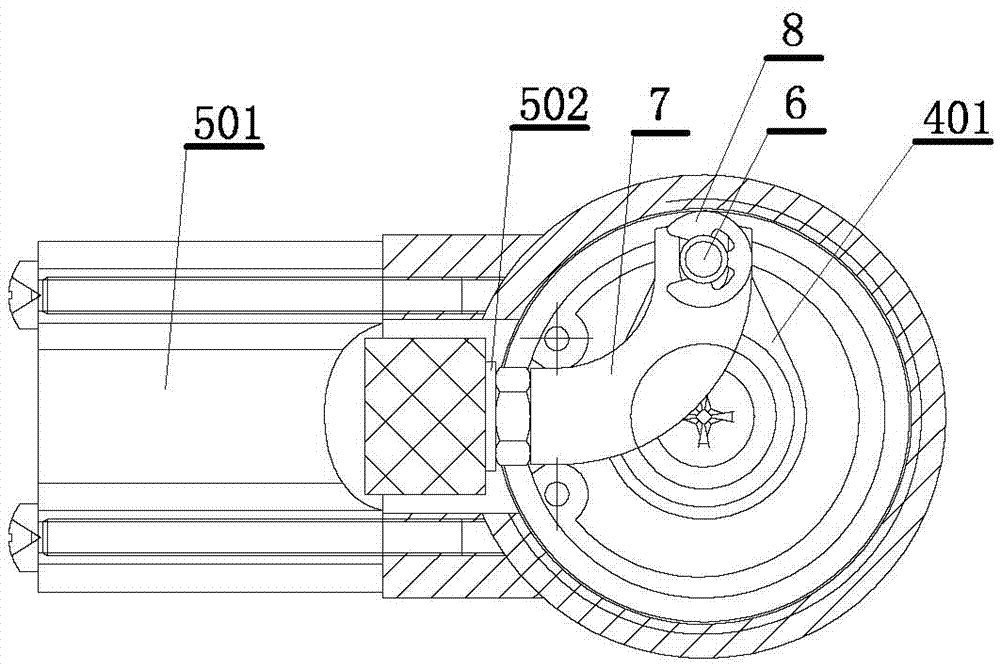

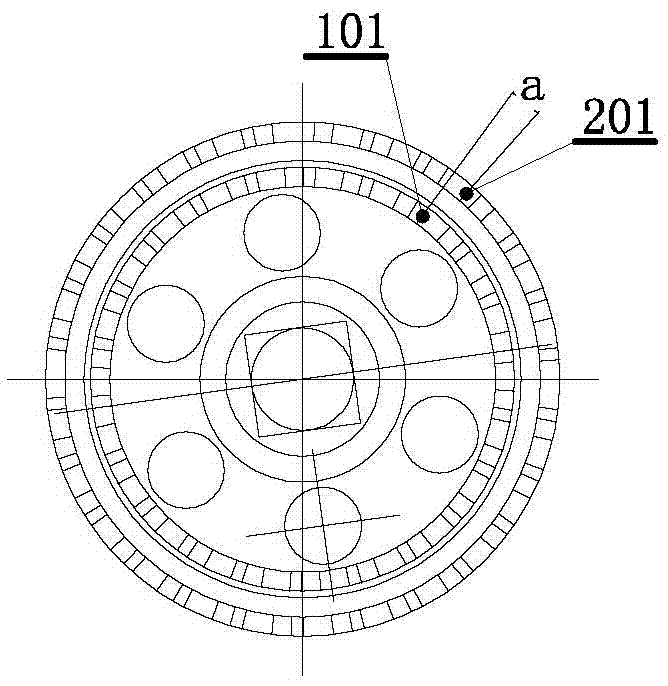

[0025] A woven bag grabbing mechanism. The mechanism includes a first claw body and a second claw body. The first claw body is movably positioned on a side surface of the second claw body. The first claw body and the second claw body can It is a flat or semi-arc shape, as a preferred solution, such as figure 1 As shown, the first claw body is an internal tooth claw body 1, the second claw body is an external tooth claw body 2, the internal tooth claw body and the external tooth claw body are both cylindrical and annular, and the internal tooth claw body The bearing 3 is rotatably positioned in the external tooth claw body. The end faces of the first claw body and the second claw body at the same position are respectively provided with pointed teeth 101 and 201 at intervals. The tooth tips of the shaped teeth are on the same horizontal plane, and the distance between the tooth tips of the inner tooth claw body and the outer tooth claw tooth tips is equal to or greater than the wi...

Embodiment 2

[0031] A woven bag grabbing system, such as Figure 5 with Image 6 As shown, the system includes a conveyor belt 9 for conveying woven bags. A movable bracket 10 is arranged above the conveyor belt. The bracket can be moved horizontally or rotated according to the needs of the packaging machine. The bracket is perpendicular to the plane of the conveyor belt. A controllable telescopic arm 11 is provided, and the woven bag grasping mechanism 12 described in Example 1 is connected to the controllable telescopic arm. Therefore, all the contents of the woven bag grasping mechanism in Example 1 should be regarded as the present embodiment The technical features are not repeated here; in this embodiment, in order to realize the grasping of the woven bag, a controller (not shown in the figure) connects the controllable telescopic arm and the driving device of the woven bag grasping mechanism Realize automatic bag grab control. Figure 5 The schematic diagram of the system structure fo...

Embodiment 3

[0036] A bag grabbing method based on the woven bag grabbing system described in Example 2. Therefore, the content in Example 2 should be regarded as the content in this embodiment. In the method of this embodiment, the content about the system should be The contents in Examples 1 and 2 are based on the basis and will not be repeated here. The method in this example is implemented on the basis of optimizing the strength system. The system includes a conveyor belt for conveying woven bags, and A movable bracket is arranged above, and the bracket is arranged with a controllable telescopic arm perpendicular to the plane of the conveyor belt. The controllable telescopic arm is symmetrically connected with two woven bag grabbing bags on both sides of the controllable telescopic arm through a horizontal connecting rod. Mechanism, the pointed teeth of the bag-grabbing mechanism are two intersecting opposite sides parallel to the twisting direction and the same direction is less than 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com