adaptive impact bed

An adaptive and buffer bed technology, applied in the field of conveying machinery, can solve the problems of smashing the conveyor belt and buffer rollers, increasing the possibility of tearing the conveyor belt, and increasing the running resistance of the whole machine, so as to improve the service life. , The effect of uniform force and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

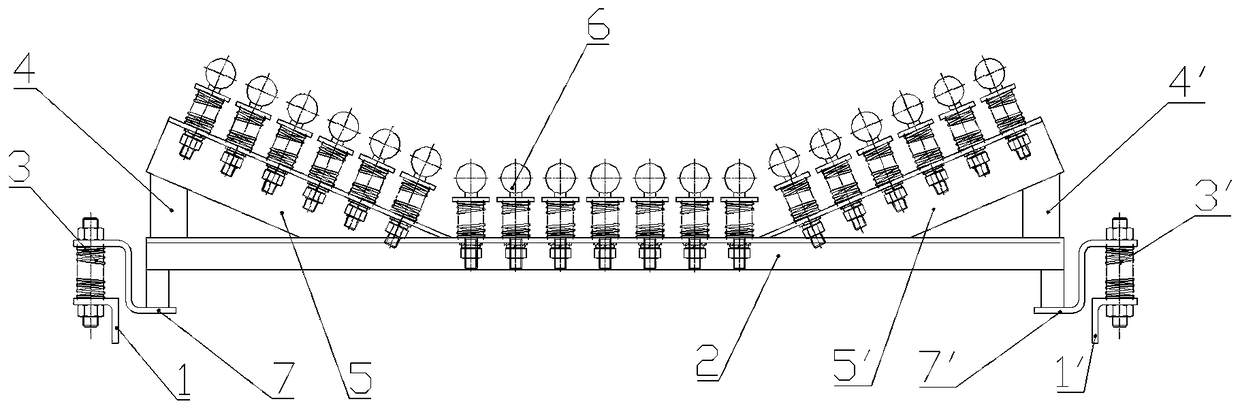

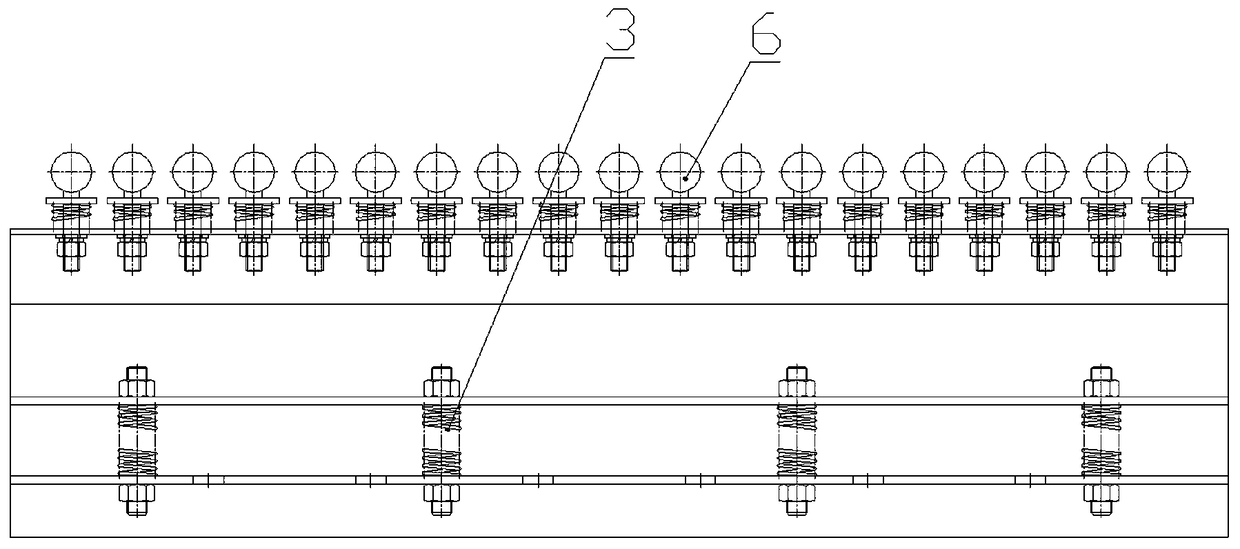

[0012] Such as figure 1 , figure 2 , image 3 It can be seen that the adaptive impact bed of this embodiment includes a bed base 2, and the two ends of the bed base 2 are respectively provided with left and right connecting plates 5, 5' via left and right support plates 4, 4', The left and right connecting plates 5, 5' cooperate with the bed base 2 to form a U-shaped groove, and the upper end surface of the U-shaped groove is uniformly provided with a plurality of through holes, and a buffer block assembly 6 is movably arranged on the through holes .

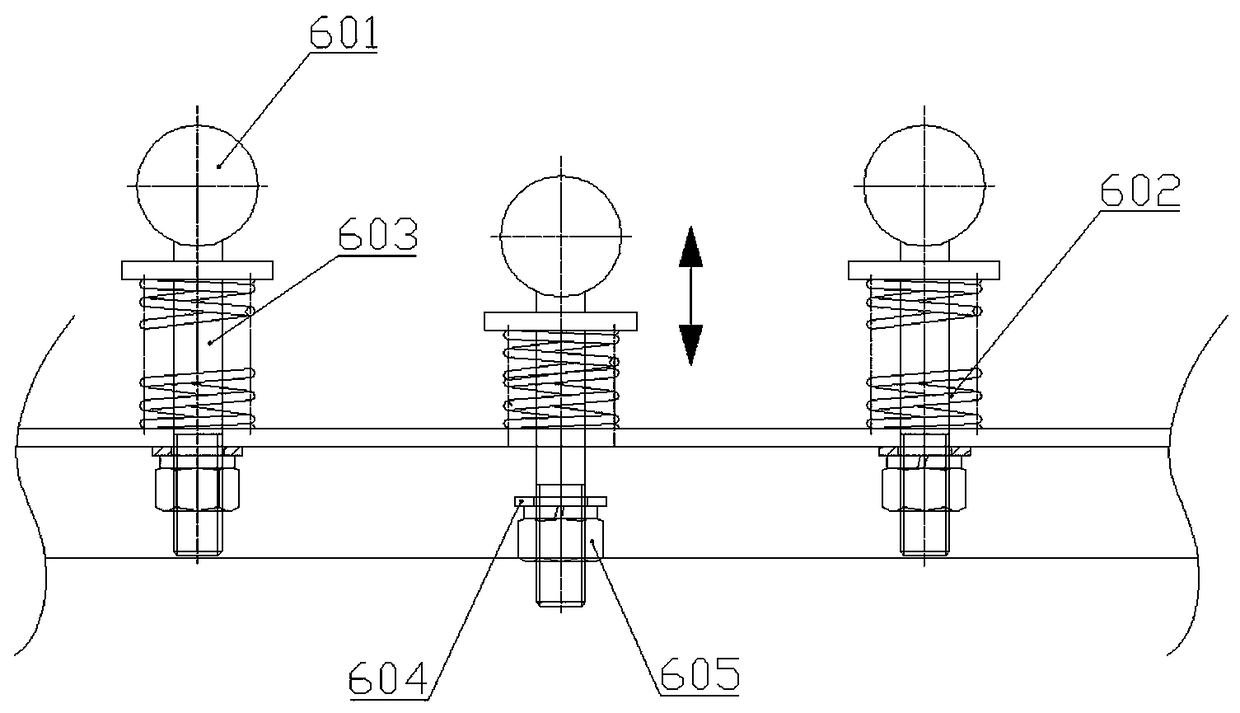

[0013] The buffer block assembly 6 includes a spherical buffer block 601, a compression spring 602 and a support column 603, the spherical buffer block 601 is connected to the support column 603, and the compression spring 602 is sleeved on the support column 603 , the end of the support column 603 passes through the through hole on the upper end surface of the U-shaped groove and is connected to the limiting device, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com