Isolated rapid singeing production line

An isolated, production line technology, applied in singeing, heating/cooling fabrics, textiles and papermaking, etc., can solve problems such as incomplete singeing, damage to the main body of the fabric, and the effect of combing, so as to avoid damage, avoid damage, and protect the fabric Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

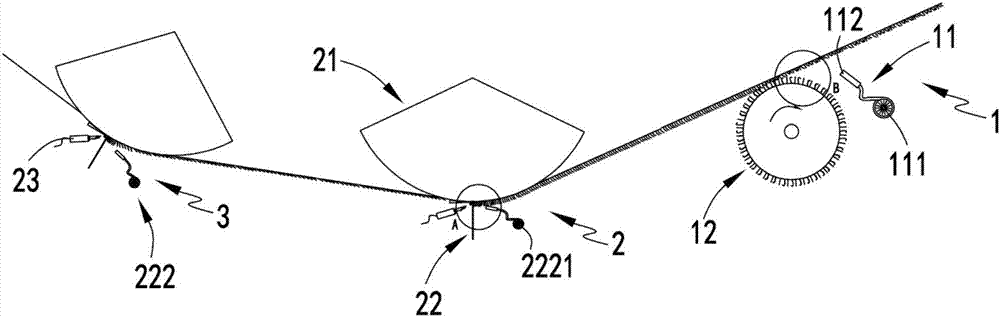

[0039] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a kind of isolated fast singeing production line comprises a combing part 1, and the combing part 1 includes a blowing mechanism 11 for blowing the hair on the surface of the fabric and a blowing mechanism 11 arranged at the rear end of the blowing mechanism 11 for blowing the surface of the fabric. A combing mechanism 12 for combing loose hair;

[0040] A first-level singeing part 2, the first-level singeing part 2 is arranged at the rear end of the combing mechanism 12, and the first-level singeing part 2 is used to perform a first-level singeing process on the finished combed fabric;

[0041] The secondary singeing part 3, the secondary singeing part 3 is arranged at the rear end of the primary singeing part 2, and the secondary singeing part 3 is used to perform singeing treatment on the fabric that has completed the primary singeing process ;

[0042...

Embodiment 2

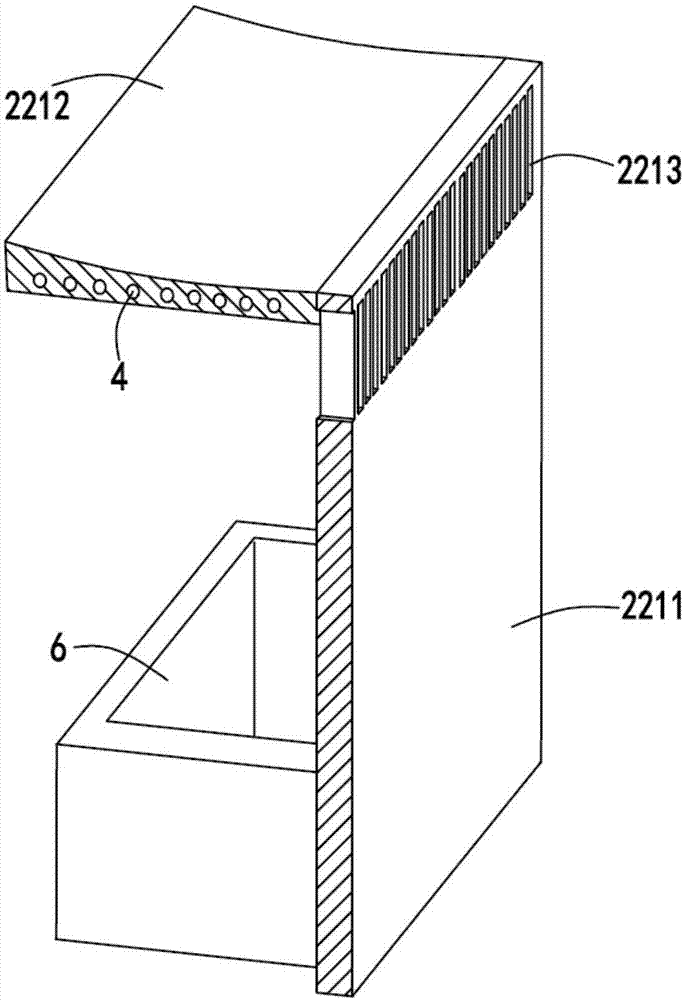

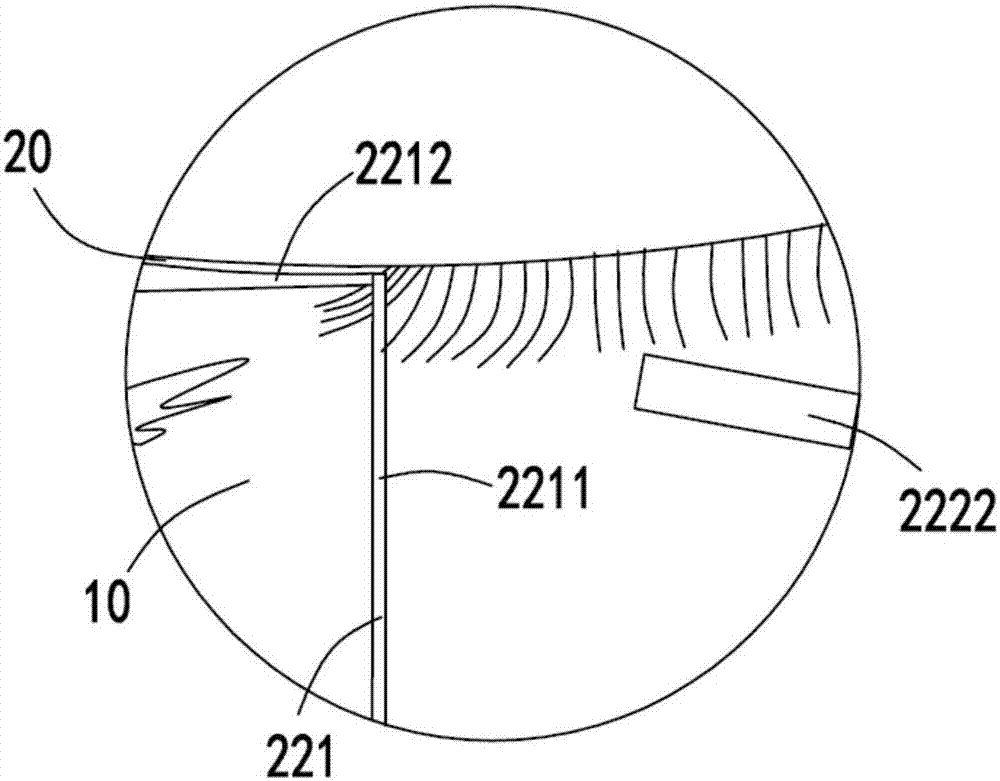

[0056] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as figure 2 As shown, the cooling guide mechanism 21 includes an arc-shaped guide 211 for conducting fabrics, and the arc-shaped guide 211 is provided with a cooling circuit a212 for cooling the fabrics before singeing and during singeing;

[0057] further, such as Figure 5 As shown, the isolation plate b2212 is provided with a cooling circuit b4;

[0058] By setting the cooling circuit a212 in the arc-shaped guide 211, the fabric before singeing and during the singeing process can be cooled, and the main body of the fabric can b...

Embodiment 3

[0060] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that a combing and ash removal mechanism 5 is also provided between the first-stage singeing part 2 and the second-stage singeing part 3, and the combing and ash removal mechanism 5 includes ash-collecting Cover 51, a carding device b52 that rotates along the outer wall of the ash-collecting cover 51 in the opposite direction of the material transmission direction. The ash-collecting cover 51 is provided with an opening 511 near the position of the material, and the carding device b52 includes a combing roller b521 and a set The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com