Luminous road plate

A board and road technology, which is applied in the field of luminous road boards, can solve the problems of lack of luminous function and single characteristics of cement boards, and achieve the effects of stable connection, stable structure, and convenient up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

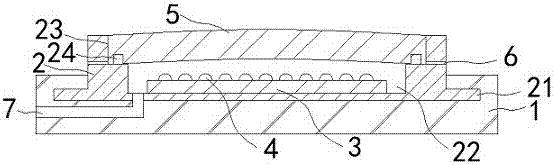

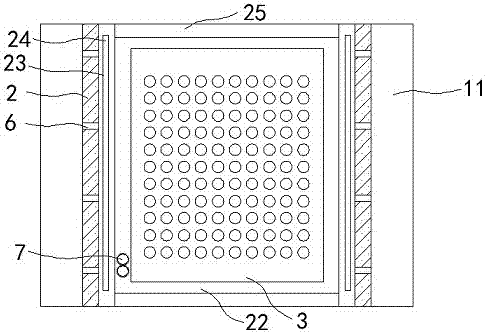

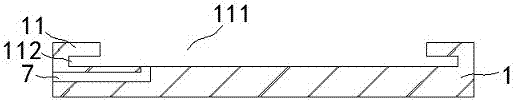

[0028] Such as Figure 1~3 Shown is a luminous road board in this embodiment, including a cement base 1, and a raised strip 11 is provided on the left and right sides of the cement base 1, and an installation cavity 111 with an upward opening is formed in the middle of the two raised strips 11. A metal base 2 is seamlessly installed in the installation cavity 111 and the metal base 2 protrudes from the installation cavity 111. There is an accommodation cavity 22 in the middle of the metal base 2. The PCB board 3 is installed in the accommodation cavity 22, and the top surface of the PCB board 3 There are a plurality of LED patch lamps 4; the metal seat 2 is provided with two notches 23 on the left and right sides of the opening of the accommodating cavity 22, and the left and right ends of a toughened glass plate 5 are correspondingly snapped on the two notches 23 and The top surface of tempered glass plate 5 is flush with the top surface of metal seat 2 .

[0029] The metal ...

Embodiment 2

[0045] Such as Figure 2~4Shown is a luminous road board in this embodiment, including a cement base 1, and a raised strip 11 is provided on the left and right sides of the cement base 1, and an installation cavity 111 with an upward opening is formed in the middle of the two raised strips 11. A metal base 2 is seamlessly installed in the installation cavity 111 and the metal base 2 protrudes from the installation cavity 111. A storage cavity 22 is provided in the middle of the metal base 2, and a plurality of lifting devices are provided on the bottom surface of the storage cavity 22. 8. A horizontal PCB board 3 is installed on the top of a plurality of lifting devices 8, and a plurality of LED patch lamps 4 are arranged on the top surface of the PCB board 3; Notches 23 , the left and right ends of a tempered glass plate 5 are correspondingly clamped on the two notches 23 and the top surface of the tempered glass plate 5 is flush with the top surface of the metal seat 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com