Rapidly levelable prefabricated assembled bridge pier structure and its construction method

A prefabricated assembly and bridge pier technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as high requirements for prefabricated parts technology level and degree of transportation protection, non-reusable leveling devices, and inability to meet precise positioning requirements. , to achieve the effect of saving construction period, rapid leveling, and rapid leveling and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0050] The invention discloses a construction method of a prefabricated assembled bridge pier structure capable of fast levelling, which comprises the following steps:

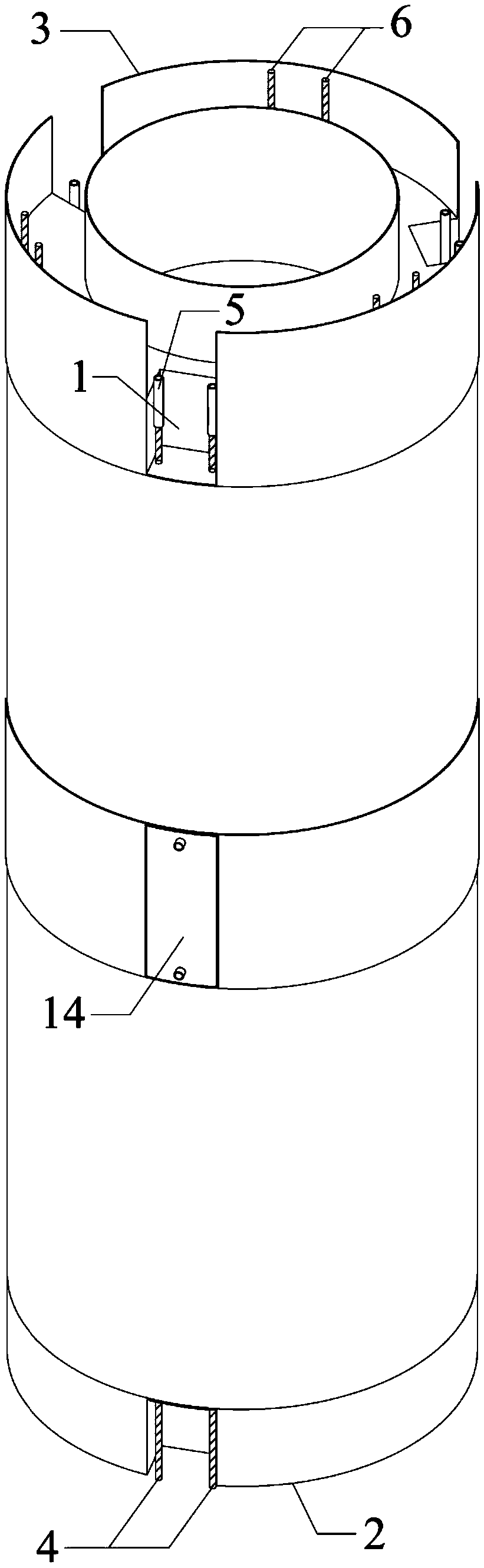

[0051] Step 1: Prepare the following materials, including several prefabricated concrete pier sections to be assembled, and prepare a double-wall steel base 2, a double-wall steel sleeve 3, and six connecting steel bars 4 for each precast concrete pier section. Six positioning steel bars 6, three jacks 13 and 3 steel shields 14.

[0052] in:

[0053] The prefabricated concrete pier segment can be a hollow pier or a solid pier, and the section form can be circular, rectangular or square.

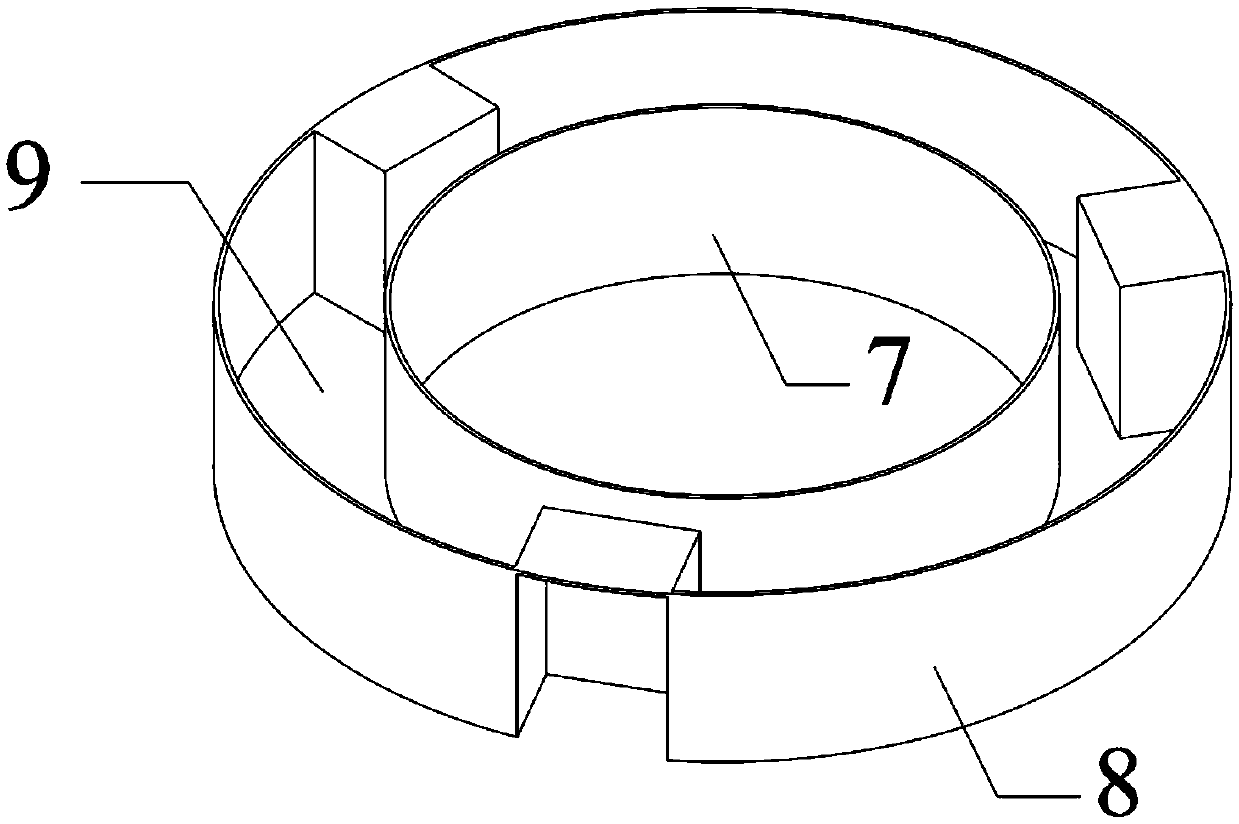

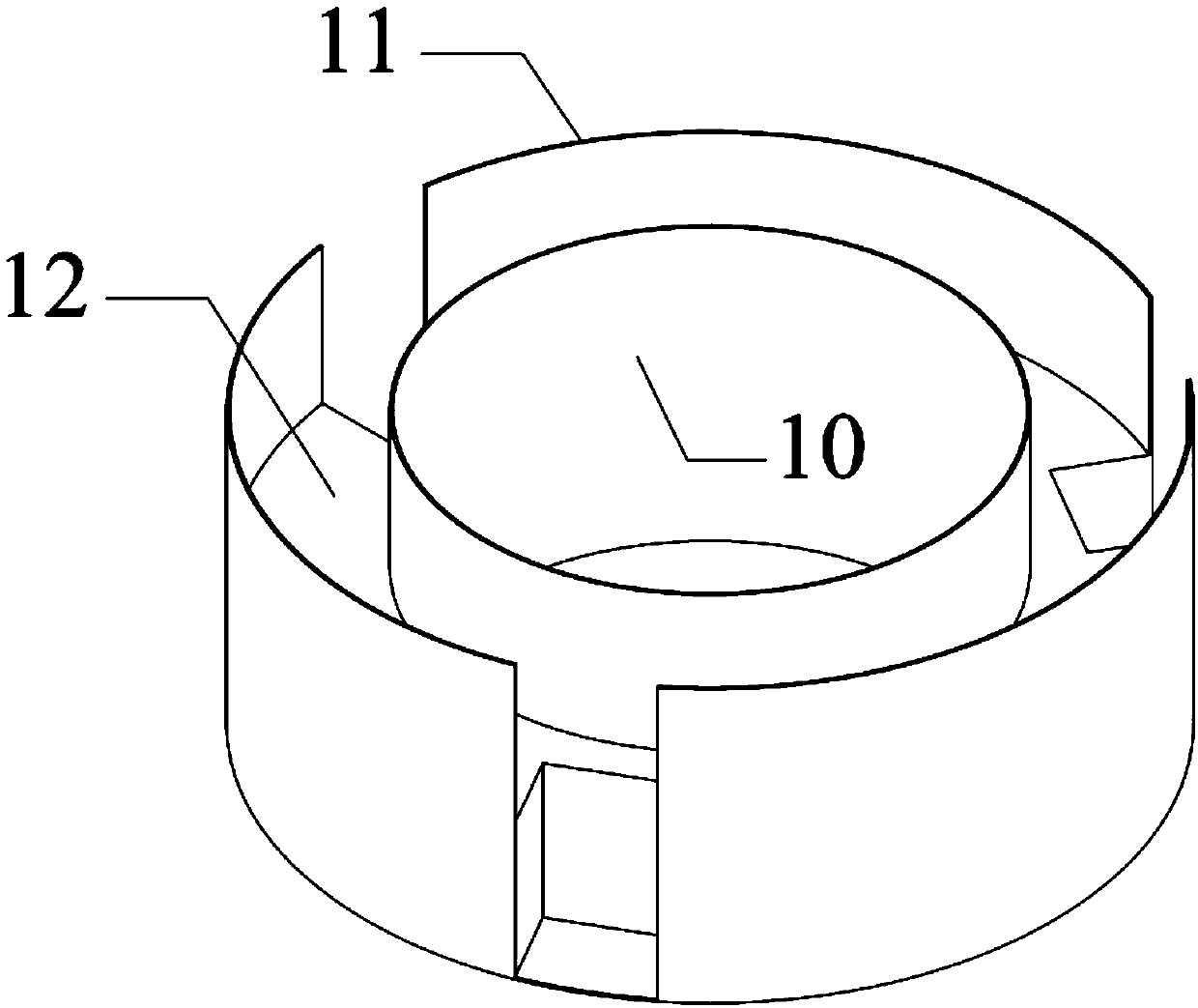

[0054] The upper and lower parts of each prefabricated concrete pier segment are correspondingly and uniformly distributed with three "["-shaped grooves a1 along the circumferential direction; between two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com