High-precision intelligent weighing system

An intelligent weighing and high-precision technology, applied in weighing, measuring devices, instruments, etc., can solve problems such as inaccurate detection results, different weight sensors, and influence of normal working conditions, so as to improve accuracy and accuracy , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

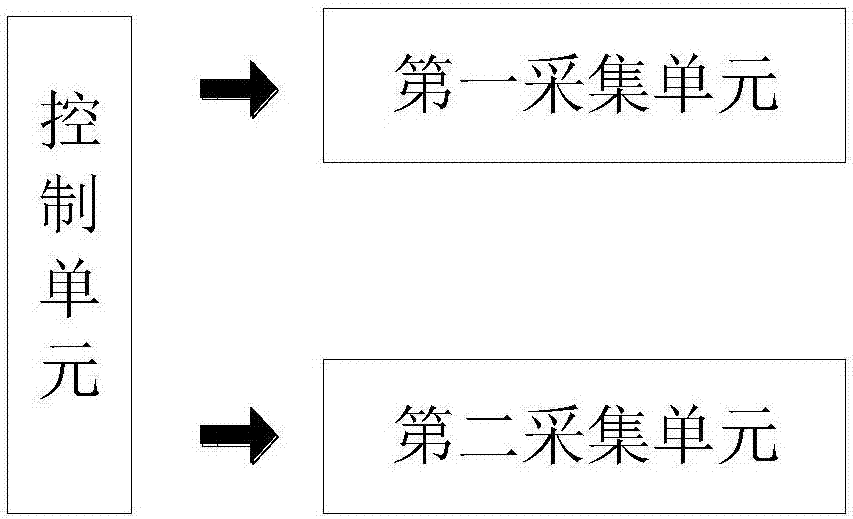

[0021] like figure 1 as shown, figure 1 It is a high-precision intelligent weighing system proposed by the present invention.

[0022] refer to figure 1 , the high-precision intelligent weighing system proposed by the present invention includes:

[0023] The first acquisition unit is used to collect the initial weight W of the target item; the first acquisition unit includes a plurality of acquisition modules, and the installation positions of the plurality of acquisition modules are different, and the initial weight of the target item can be checked from different angles and different positions. Acquisition ensures the comprehensiveness and reliability of the collection results; and any collection module includes multiple weight sensors, the use of multiple weight sensors can further improve the accuracy of the initial weight collection of the target item, and multiple weight sensors can be obtained from different The angle and different positions collect the weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com