Friction and wearing test device with tension and compression mechanisms and test method

A technology of friction and wear testing equipment, which is applied in the direction of testing wear resistance, etc., can solve the problems of material damage, limited, and inability to accurately grasp the time and size of crack initiation, and achieve accurate and stable tension/pressure, and experimental operation process Simple, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

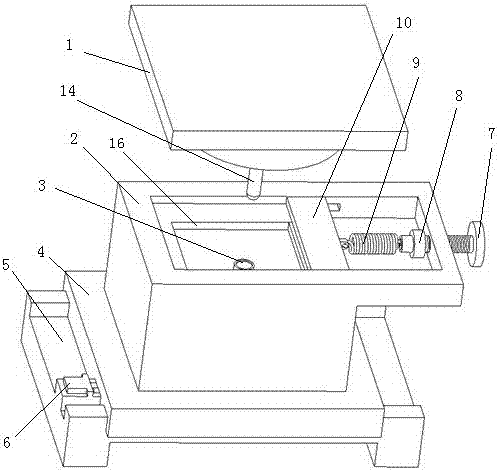

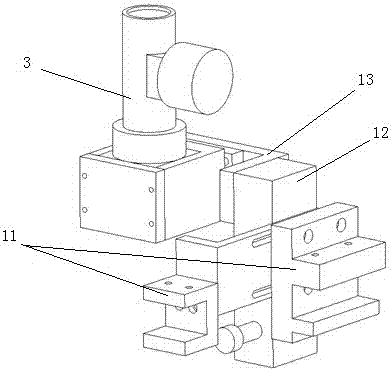

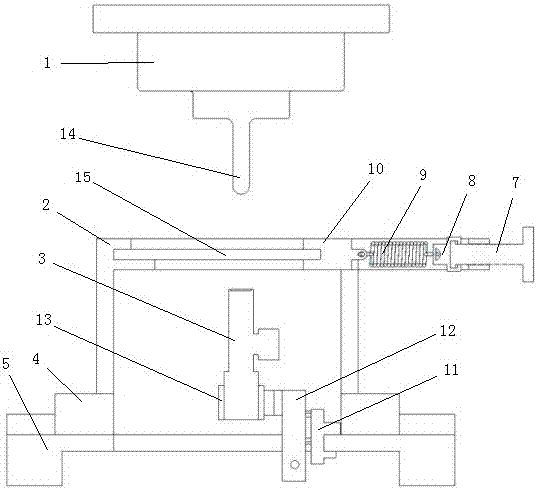

[0035] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0036] It can be seen from the accompanying drawings that this solution includes a frame, a linear guide platform, a sample stage, a stretching base, a workpiece clamping mechanism, a reverse observation mechanism, and a friction ball fixture; the linear guide platform is set on the frame; The sample stage is fixed on the linear guide rail platform; the stretching base is fixed on the sample stage; the middle part of the stretching base is hollowed out; the workpiece clamping mechanism is set in the stretching base; the reverse observation mechanism is set under the stretching base Inside the sample table; the friction ball fixture is fixed on the frame above the stretching mechanism; the linear guide mechanism can slide on the frame.

[0037] A pressure head is fixed below the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com