Method for calculating control residual stress processing parameters via parameter inversion

一种残余应力、加工参数的技术,应用在通过参数反演计算调控残余应力加工参数领域,达到改善残余应力分布、操作简便、计算时间短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

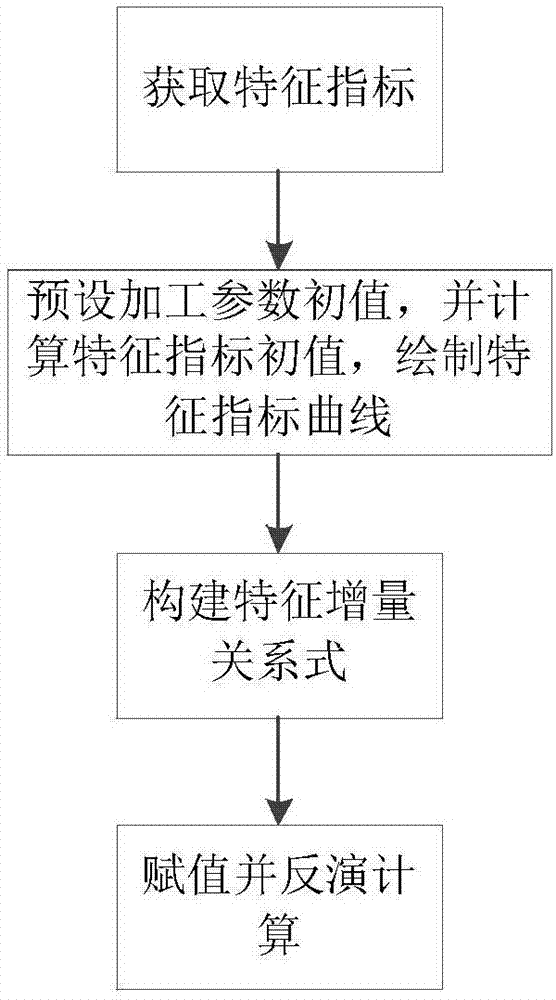

[0036] figure 1 It is a flow chart of a method for adjusting and controlling residual stress processing parameters through parameter inversion calculation constructed according to the preferred embodiment of the present invention, such as figure 1 As shown, the method will be described below with an example of residual stress in orthogonal cutting machining:

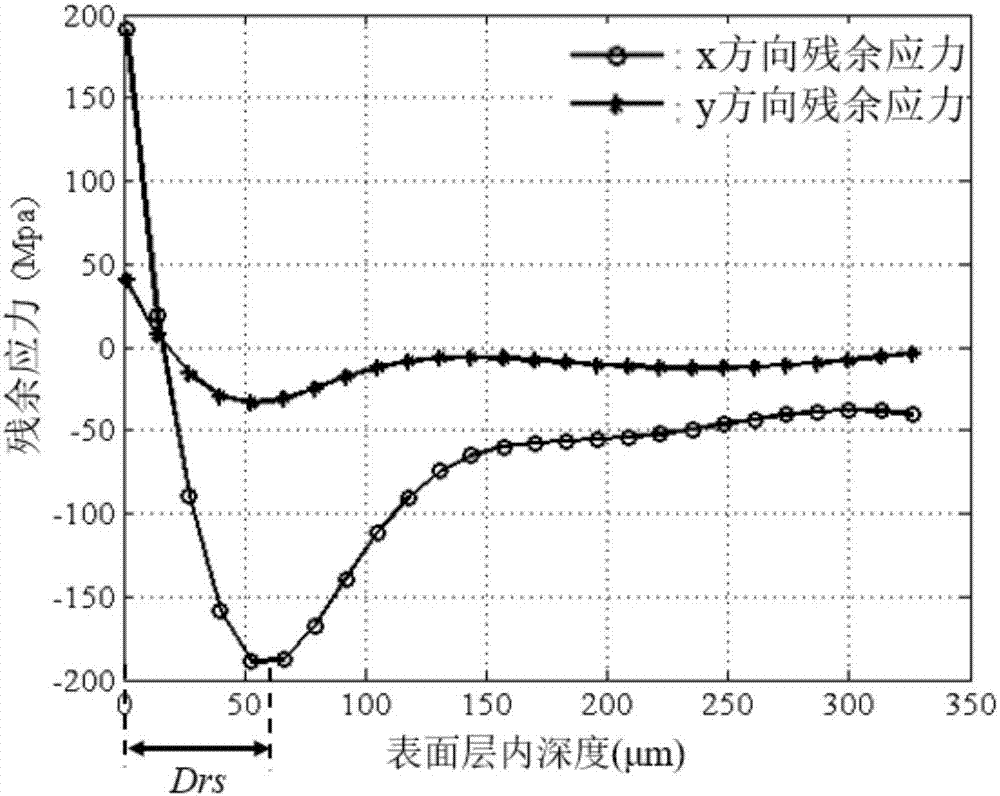

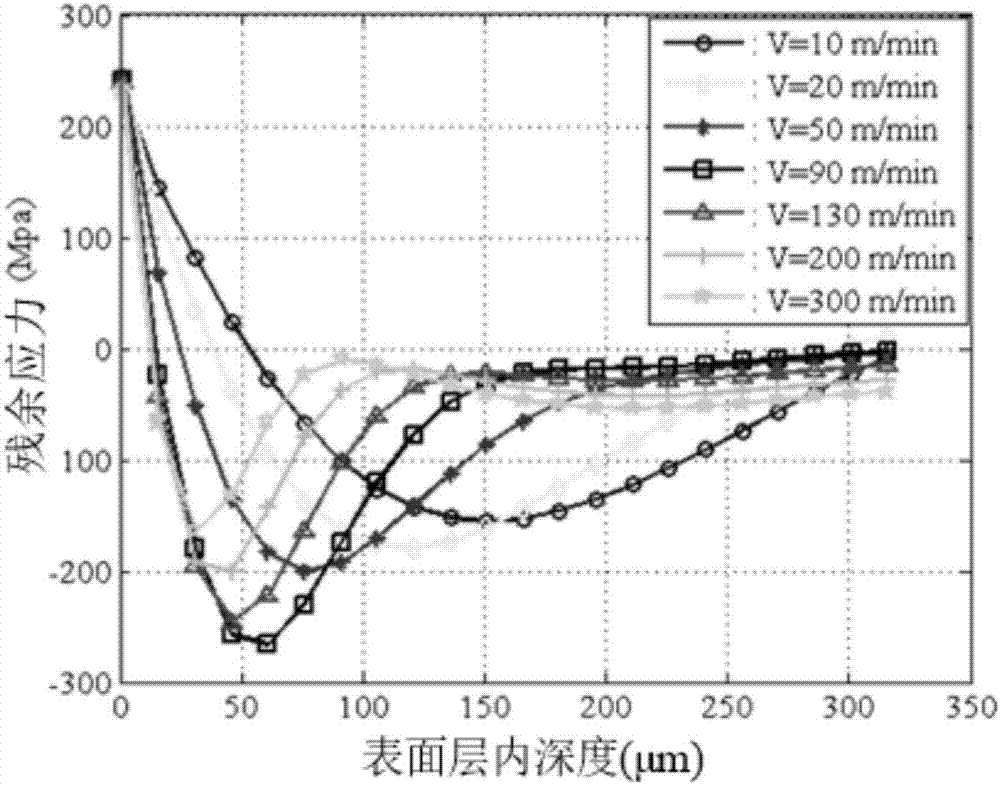

[0037] (a) Determine the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com