Stirring device

A technology of stirring device and stirring paddle, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of uneven density, long stirring time, insufficient stirring, etc. Improve production efficiency and stir evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

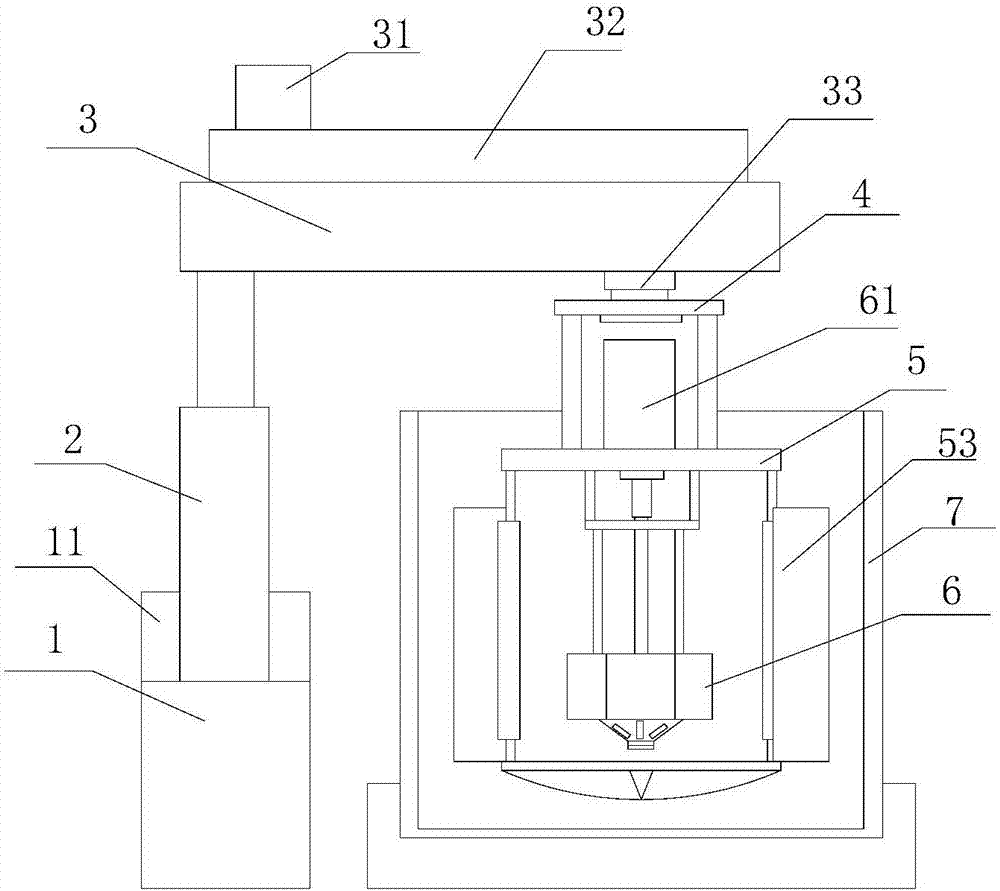

[0015] refer to Figure 1 to Figure 4 A stirring device of the present invention comprises a base 1, a supporting telescopic shaft 2, a driving base 3, a driving mounting frame 4, a fixed stirring mechanism 5, a movable stirring mechanism 6 and a mixing bucket 7, and a supporting telescopic shaft is installed on the base 1. Axle 2, said supporting telescopic shaft 2 is provided with drive base 3, and the bottom of described drive base 3 is provided with drive shaft 33, and described drive shaft 33 is connected with drive mount 4, and the bottom of described drive mount 4 is installed There is a fixed stirring mechanism 5, and the movable stirring mechanism 6 is installed below the fixed stirring mechanism 5. The movable stirring mechanism 6 is provided with a driving cylinder 61 and a stirring part 64, and the driving cylinder 61 drives the stirring part 64 to move up and down. A plurality of first stirring paddles 53 are installed on the periphery of the fixed stirring mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com