Building rubbish disposal method

A technology for construction waste and disposal methods, which is applied in grain treatment, sustainable waste treatment, climate sustainability, etc., can solve the problems of high transportation costs, construction waste utilization rate of less than 5%, low added value, etc., to achieve The effect of saving building resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

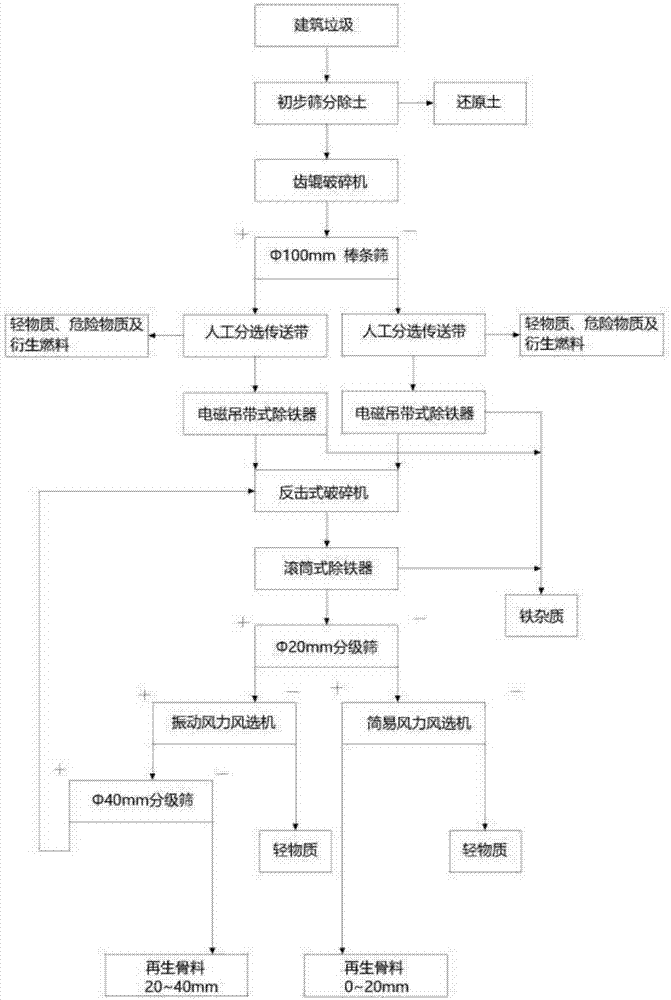

[0027] Such as figure 1 As shown, the preferred embodiment of the present invention provides a kind of construction waste disposal method, and described construction waste disposal method comprises the following steps:

[0028] S10: A soil removal process, wherein the soil removal process is used to separate the soil from the block of construction waste.

[0029] Specifically, the automobile transports the construction waste to the storage yard for centralized storage, and uses a forklift to load the material into the feeding hopper of the apron feeder (including a homogenizer). The material in the funnel enters the apron feeder, and the material The machine moves forward at a certain speed (v=0-0.1m / s), and is evenly fed to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com